Filling and rotating all-in-one machine

An all-in-one machine and cover technology, applied to packaging machines, conveyor objects, packaging, etc., can solve the problems of high technical level requirements for adjustment personnel, failure of machines to automatically identify fault alarms, and lower technical level of operators, etc., to achieve Guaranteed the quality of filling and packaging, simple mechanical and electrical debugging, and the effect of lowering the technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In the following description, numerous specific details are set forth in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other instances, some technical features known in the art have not been described in order to avoid obscuring the present invention.

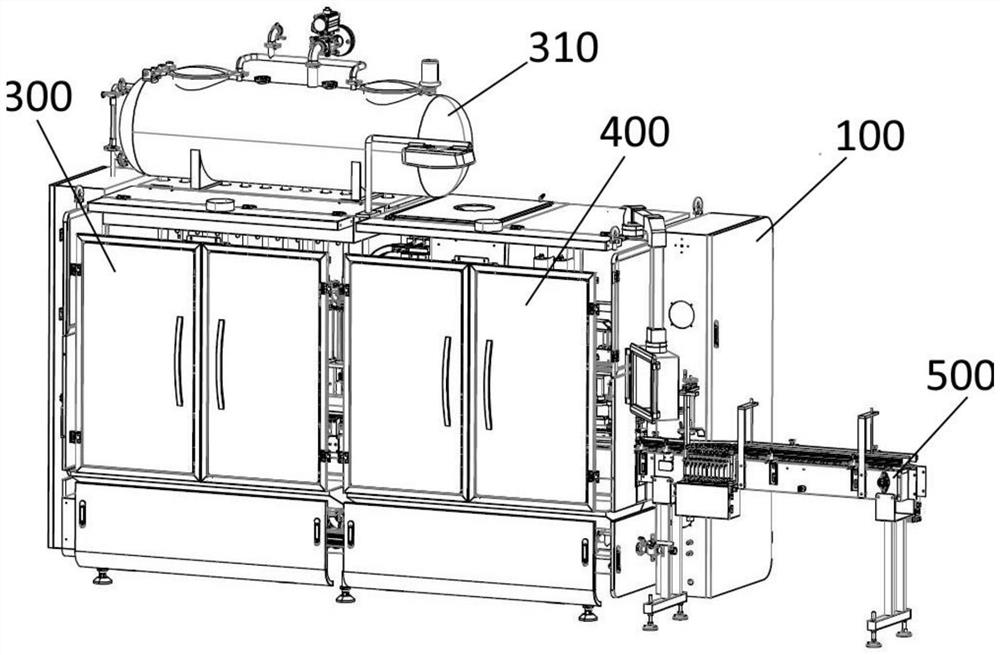

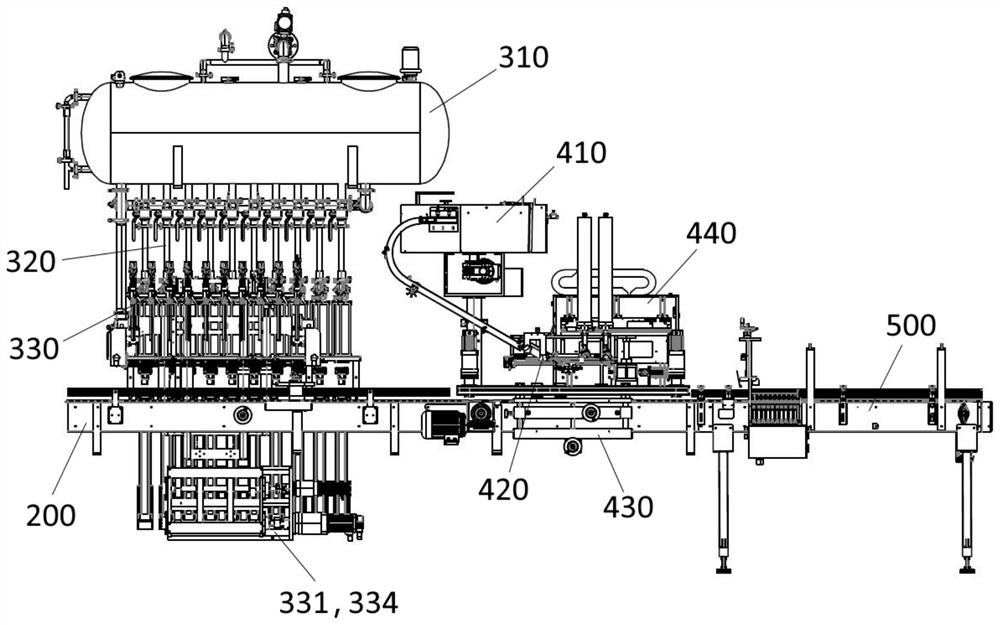

[0060] See attached Figures 1 to 2 , In this embodiment, the applicable material packaging range of the filling and spinning integrated function can cover the fields of chemical oil, food and beverage, etc., the filling dosage range is in the range of 80-1000mL, and the packaging materials used in the equipment can be suitable for plastic bottles, glass bottles, etc. The filling and rotating integrated machine includes: a frame 100 , a conveying mechanism 200 , a filling mechanism 300 and a capping mechanism 400 .

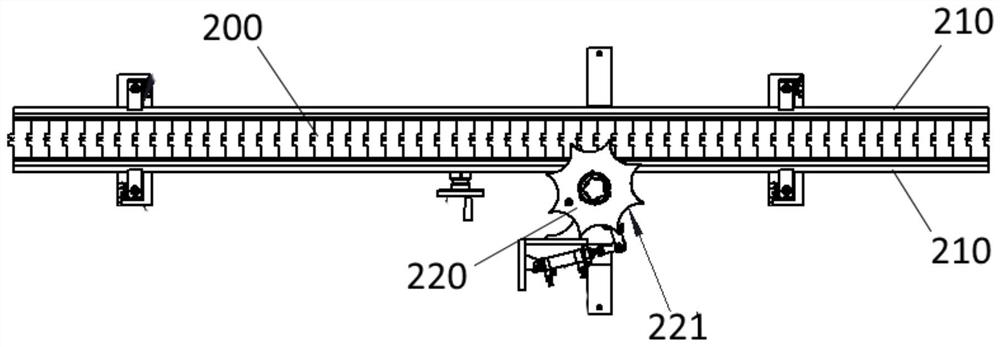

[0061] The conveying mechanism 200 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com