Multiple-stage type roll paper color printing drying box

A drying box and multi-stage technology, applied in the field of multi-stage roll paper color printing drying box, can solve the problems of affecting the quality of roll paper, low degree of automation, and low work efficiency, so as to shorten the winding production line and occupy space The effect of small area and easy winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

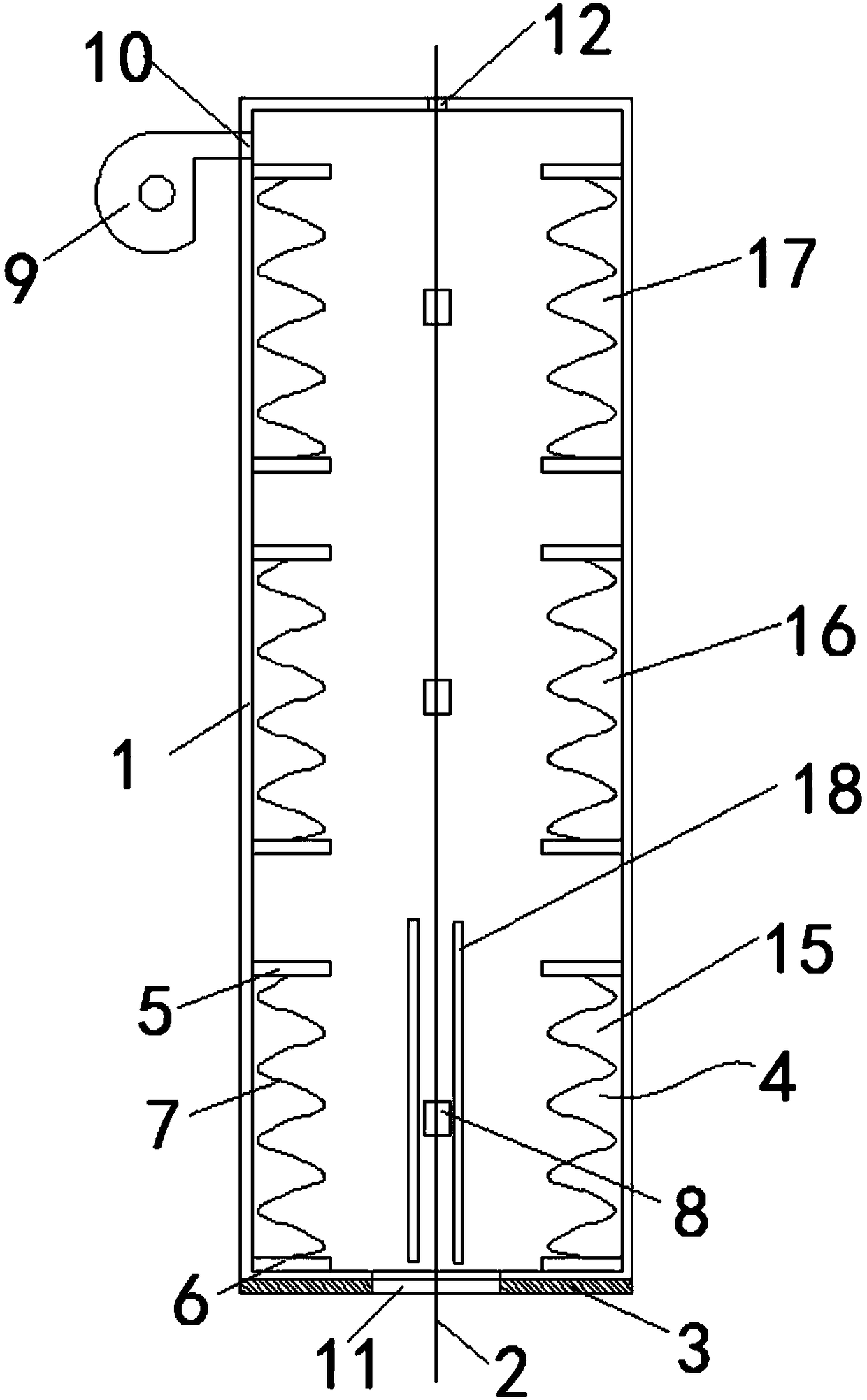

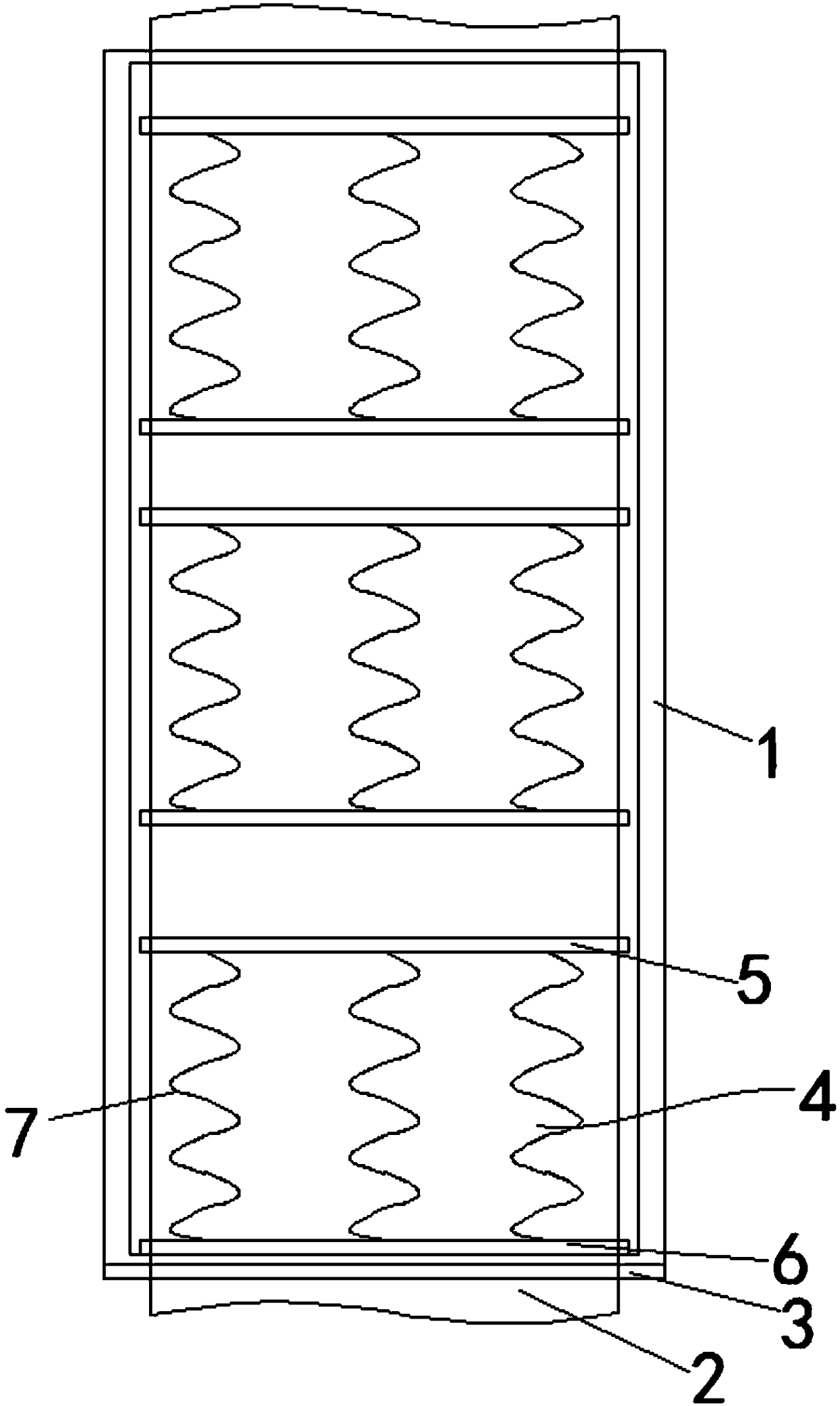

[0017] Such as Figure 1-Figure 4 As shown, the present invention is a multi-stage roll paper color printing drying box, the drying box includes a box body 1, the box body 1 is vertically arranged, and the bottom and top of the box body 1 are respectively provided with paper tape inlets and the paper tape outlet, the box body 1 is located between the paper tape entrance and the paper tape exit, and is sequentially provided with a preheating section 15 heating device located on one or both sides of the paper tape 2, and a high-temperature drying section 16 for heating device and drying section 17 heating device, the preheating section heating device 15, the high temperature drying section heating device 16 and the drying section heating device 17 all include a horizontal positive plate 5, a negative plate 6 and no less than two vertical The heating wire 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com