Self-adaptive water level lifting and plane constraint positioning floating equipment

A plane-constrained, self-adaptive technology, applied in the directions of transportation and packaging, floating buildings, ship construction, etc., can solve the problem of no external power supply, the inability to realize adaptive water level lifting and precise positioning, and increase the complexity and cost of floating facilities and other issues to achieve the effect of adapting to changes in water level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

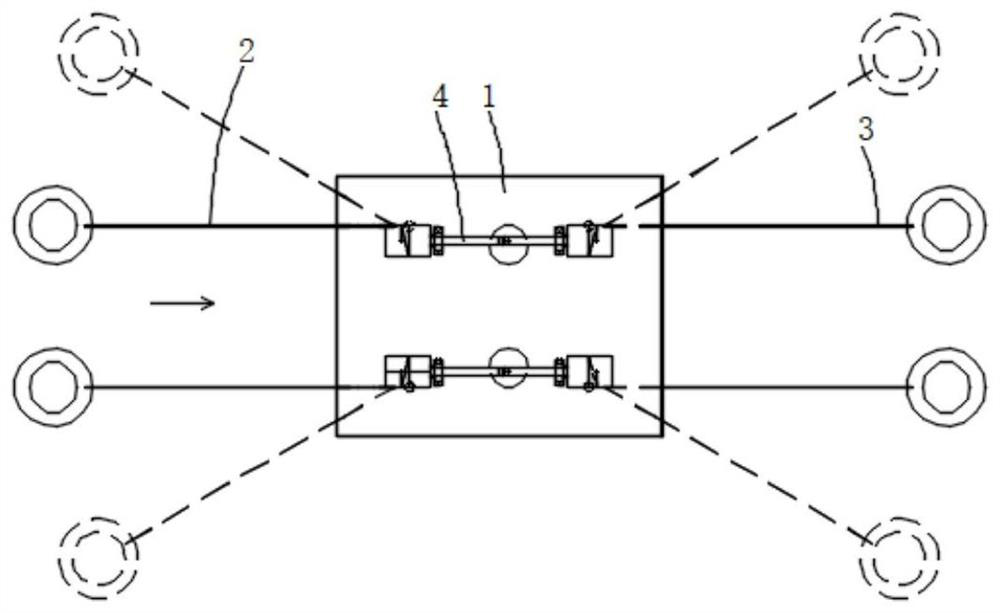

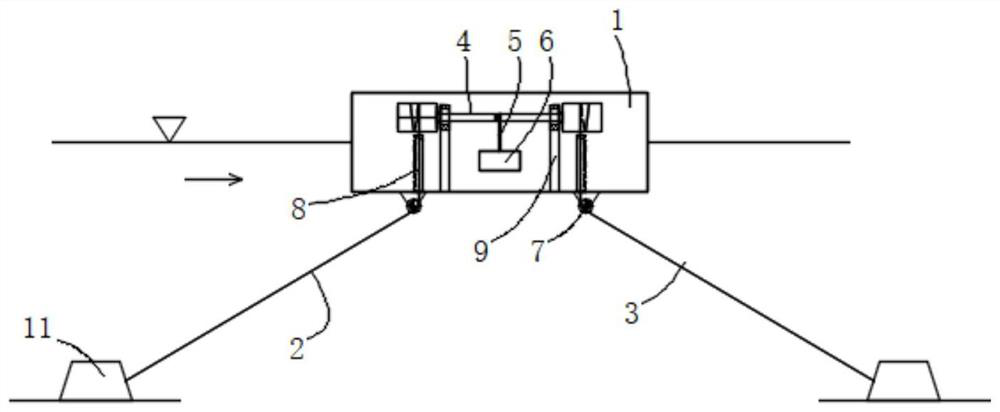

[0044] Example 1: A floating device with adaptive water level lifting and plane constraint positioning, such as Figure 1-4 As shown, it includes a floating platform 1 floating on the water surface, and also includes a floating platform self-positioning system. The floating platform self-positioning system includes a front end cable 2 arranged at one end of the floating platform facing the water flow direction and a rear cable 2 arranged at one end facing away from the water flow direction. The end cable 3, the lower end of the front end cable 2 is anchored under water obliquely forward, the lower end of the rear end cable 3 is anchored under water obliquely backward, and the self-positioning system of the floating platform also includes a rotating drum member 4 arranged horizontally along the direction of the water flow. 4 is rotatably mounted on the floating platform 1, the front end of the drum member has a front end cable winding section, the upper end of the front end cabl...

Embodiment 2

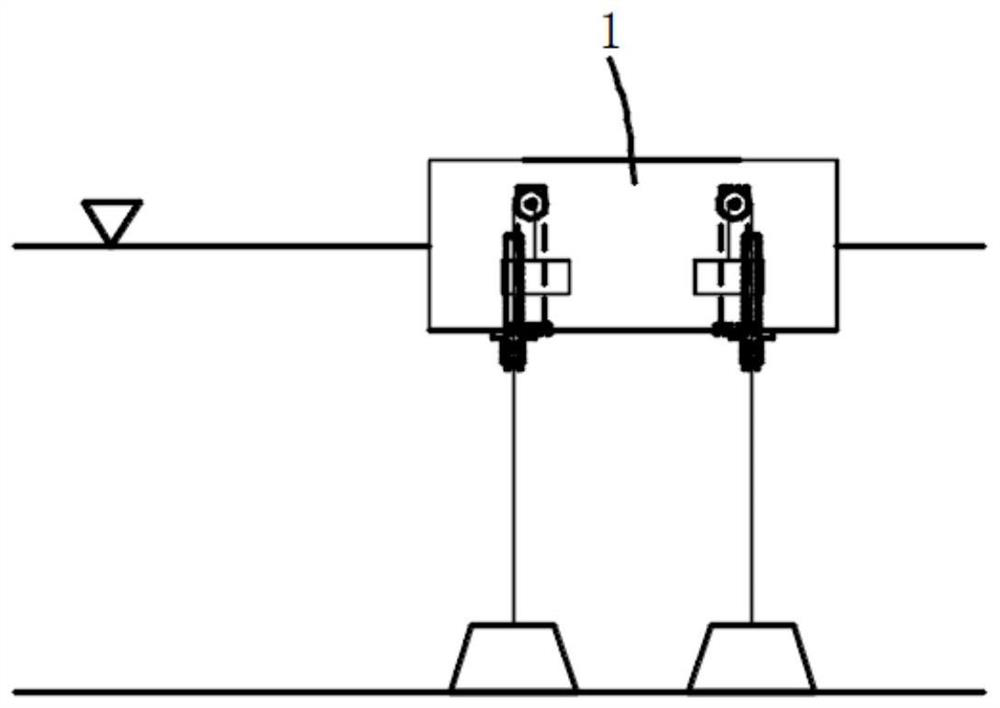

[0066] Embodiment 2: Compared with Embodiment 1, the difference between this embodiment is only that the specific implementation of the device structure is slightly different. Figure 5-6The shown self-adaptive water level lifting and plane restraint positioning floating equipment is realized, and the self-coupling floating table positioning also includes the floating equipment floating on the water surface. Self-adjusting system, the self-coupling floating platform positioning self-adjusting system includes two rotating drum members 4 ′ arranged horizontally and spaced apart. The rotating drum members 4 ′ are arranged along the water flow direction and are rotatably installed on the floating platform. The front end of the component has a front end cable winding section and is wound with a front end cable 2', and the rear end of the drum component has a rear end cable winding section and is wound with a rear end cable 3', and the lower end of the front end cable 2' faces the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com