Negative-pressure large-cloth-bag dust removal device for industrial silicon submerged arc furnace

A technology for bag dust removal and submerged arc furnace, applied in the field of submerged arc furnace, can solve the problems of leakage of large bags, influence of induced draft fan, and high filtration load of large bags, and achieve the effect of reducing filtration load and improving filtration capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

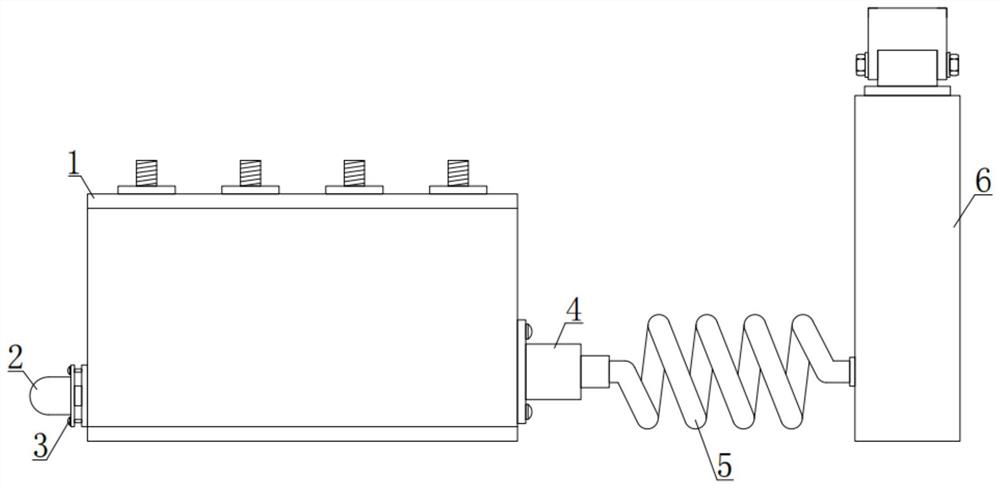

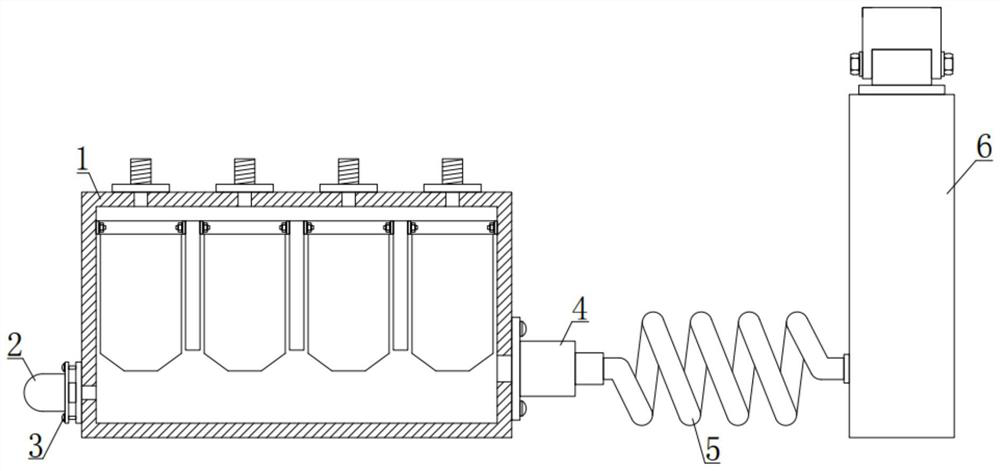

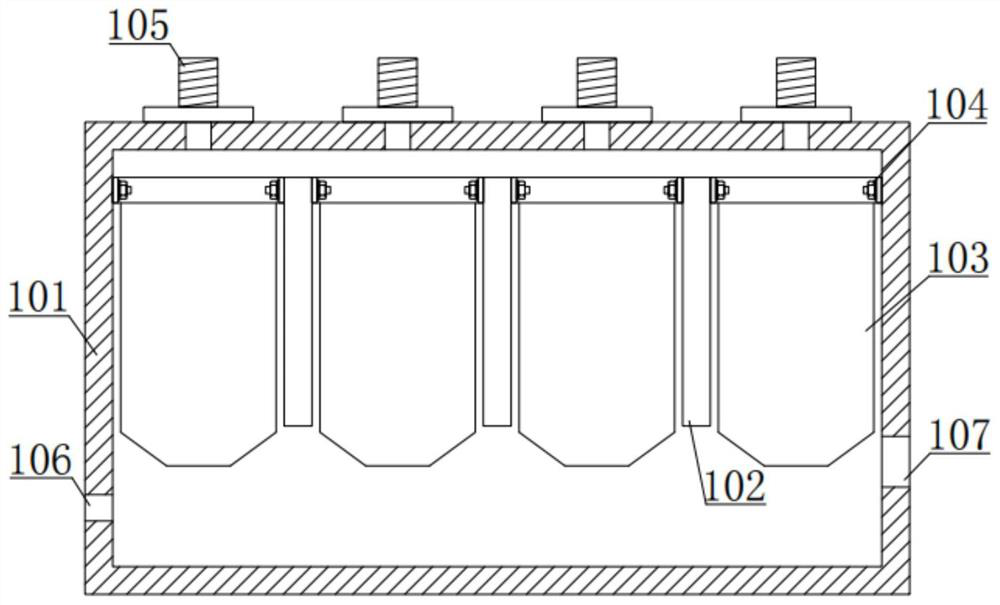

[0033] see figure 1 , an industrial silicon submerged arc furnace negative pressure large bag dust removal device, including a dust removal component 1, a sealing cover 2, a snap bolt 3, an external filter component 4, an extension pipe 5 and an induced draft fan component 6, and the lower left side of the dust removal component 1 passes through The snap bolt 3 is installed with the sealing cover 2, and the opening of the dust removal component 1 is sealed by the sealing cover 2 to prevent the leakage of smoke and dust during the dust removal process. An external filter component 4 is installed on the lower right side of the dust removal component 1 for auxiliary filtering of smoke and dust. An extension pipe 5 is installed in the external filter assembly 4, and an induced draft fan assembly 6 is installed at the end of the extended pipe 5. The external filter assembly 4 is connected with the induced draft fan assembly 6 by the extension pipe 5, and the induced draft fan assemb...

Embodiment 2

[0040] The difference between this embodiment and the first embodiment is that the internal structure of the dust bag assembly 103 is different.

[0041] The dust bag assembly 103 includes a fixed outer frame 1031, a connecting ear plate 1032, an assembly frame 1033, a bag bracket 1034, bracket bolts 1035, a bag body 1036, a snap screw 1037, a positioning nut 1038 and a secondary filter screen 1039. The outer frame is fixed. The side of the 1031 is provided with a connecting lug plate 1032. The connecting lug plate 1032 is used to assemble the connecting bolts 104. The lower side of the fixed outer frame 1031 is provided with an assembly frame 1033. The assembly frame 1033 is the overall shell of the dust bag assembly 103. The bag bracket 1034 is installed on the inner side, the bracket bolts 1035 are installed on the bag bracket 1034, and the bag bracket 1034 is installed on the inner side of the assembly frame 1033 by using the bracket bolts 1035. The lower side of the bag br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com