Lifting type compact shelf

A compact rack, lift-type technology, applied in the field of compact racks, can solve the problems of easy dust accumulation, small floor space, large floor space, etc., to achieve the effect of reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

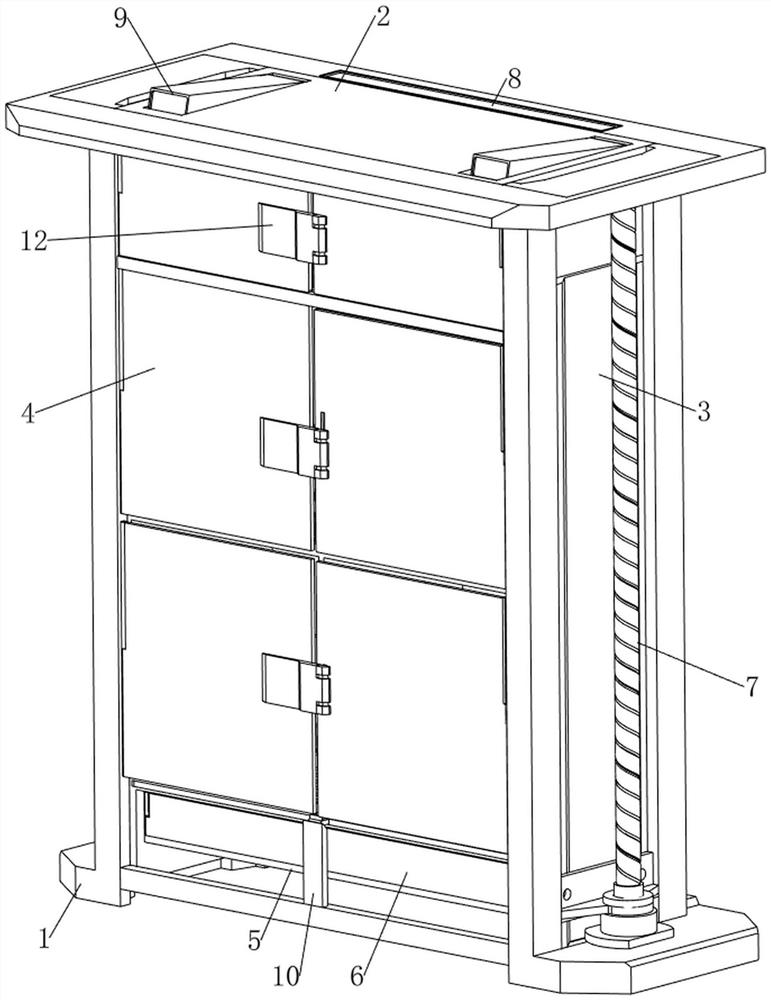

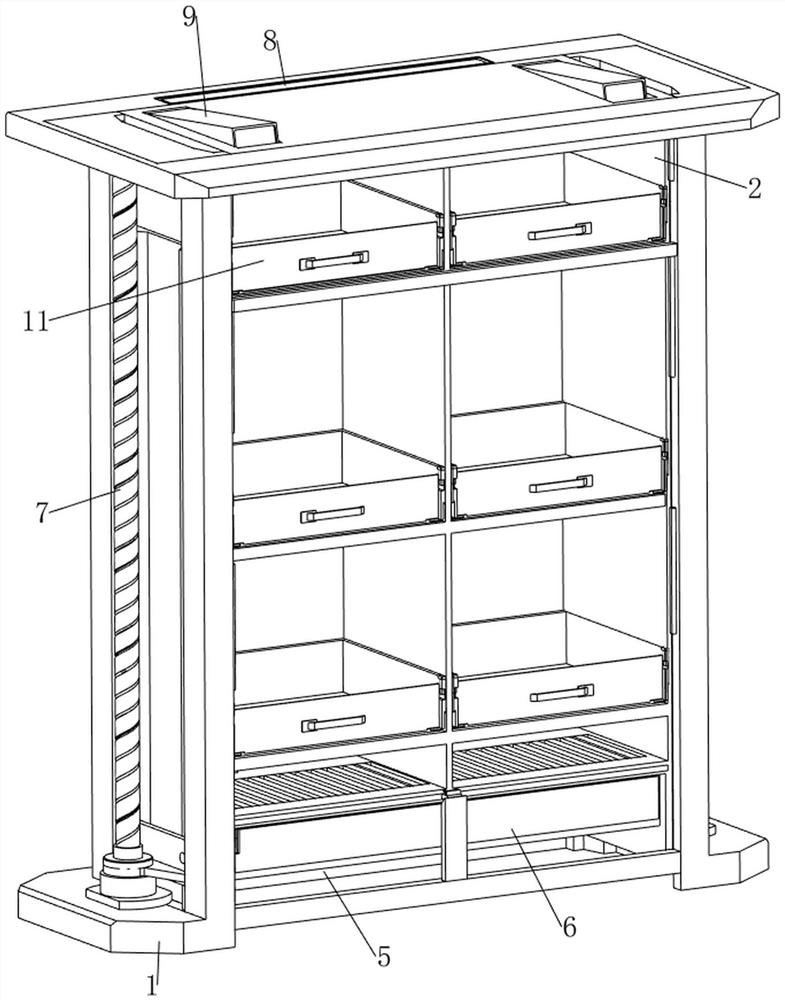

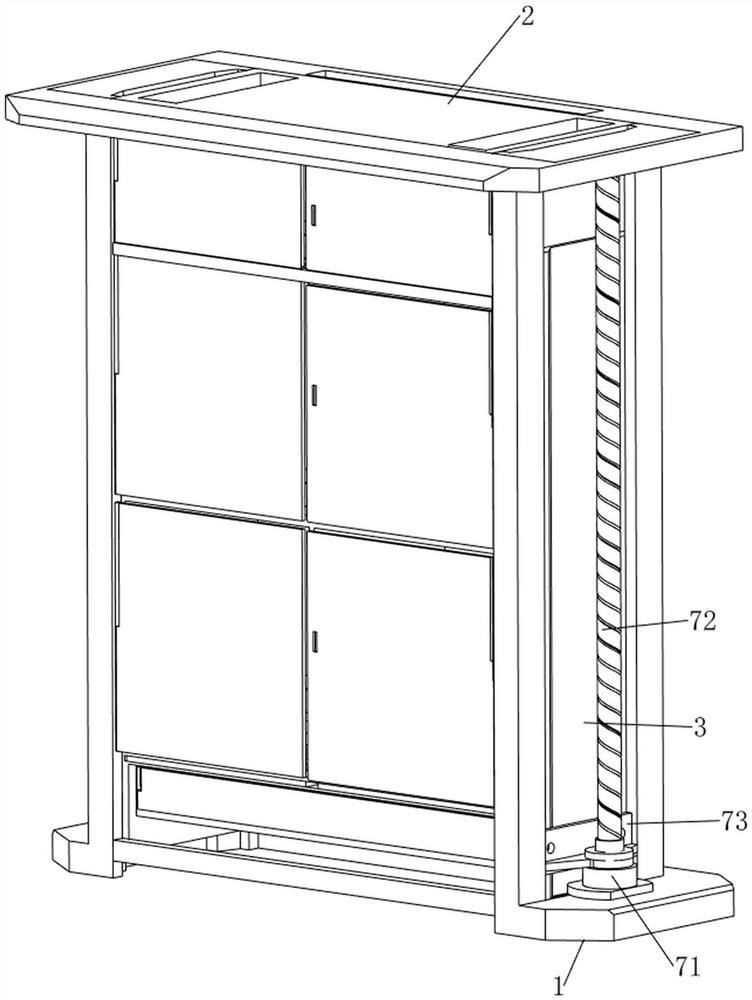

[0035] A lift-type compact rack, such as Figure 1-2 As shown, it includes a supporting slide rail 1, a cabinet 2, a slider 3, a first rotating plate 4, a storage box 5, a second rotating plate 6, a lifting mechanism 7 and a prompting mechanism 8, and the left and right sides of the supporting slide rail 1 are The sliding connection is provided with a slider 3, and a cabinet 2 is arranged between the sliders 3. The cabinet 2 is used for storing items. There are three cavities on the left and right sides of the cabinet 2 respectively. A rotating plate 4, the first rotating plate 4 can cover the front side of the cavity of the cabinet 2, a storage box 5 is slidably connected to the lower part of the cabinet 2, and a second rotating plate 6 is rotatably connected to the left front side of the storage box 5. The two rotating plates 6 are used to cover the front side of the storage box 5 , a lifting mechanism 7 is provided between the support slide rail 1 and the slider 3 to drive ...

Embodiment 2

[0040] On the basis of Example 1, as figure 1 , figure 2 , Figure 7 and Figure 8 As shown, it also includes a display mechanism 9, which can display the items placed in the cabinet 2. The display mechanism 9 includes a third rotating plate 91, a first sliding plate 92, a second telescopic spring 93, a second rotating shaft 94, and a torsion spring. 95 and the cam 96, the left and right sides of the top rear side of the cabinet 2 are rotatably connected with the third rotating plate 91, and the third rotating plate 91 is slidably connected with the first sliding plate 92, and the first sliding plate 92 can be in the first sliding plate 92. The three rotating plates 91 slide inside, and a second telescopic spring 93 is provided between the top of the first sliding plate 92 and the third rotating plate 91. Under the action of the second telescopic spring 93, the first sliding plate 92 can be driven to move and reset. , the left and right sides of the upper part of the cabin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com