Agricultural film breaking seeder with mulching film protection function

A kind of protection function and seeder technology, applied in seeder parts, agriculture, sowing, etc., can solve the problems of tearing of mulch film, loss of heat preservation and water retention function of mulch film, affecting seed survival rate, etc., and achieve the effect of adjusting the sowing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

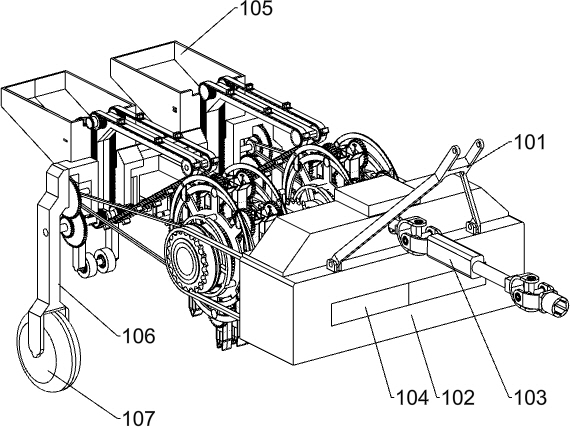

[0030] A film-breaking planter with mulch protection function for agriculture, such as Figure 1-Figure 11 As shown, a connecting frame 101 is included, and the rear end of the connecting frame 101 is hinged with a transfer case 102 for distributing power. The power input end of the transfer case 102 is universally connected with a transmission shaft 103 for transmitting power. It is universally connected with the output shaft of the tractor, and the output shaft of the tractor provides the power for this device to work. A first fixing frame 104 is fixed in the transfer case 102, and the rear end of the first fixing frame 104 is fixed with a fixing frame 104 for storing The two feeding frames 105 of the seeds are arranged symmetrically on the left and right sides, the left and right sides of the rear end of the first fixing frame 104 are fixed with a second fixing frame 106, and the lower parts of the two second fixing frames 106 are both rotated. The wheels 107 are connected,...

Embodiment 2

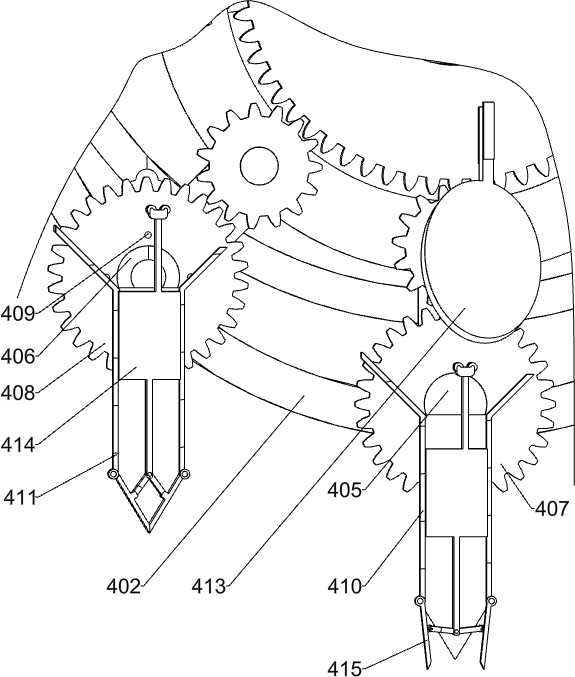

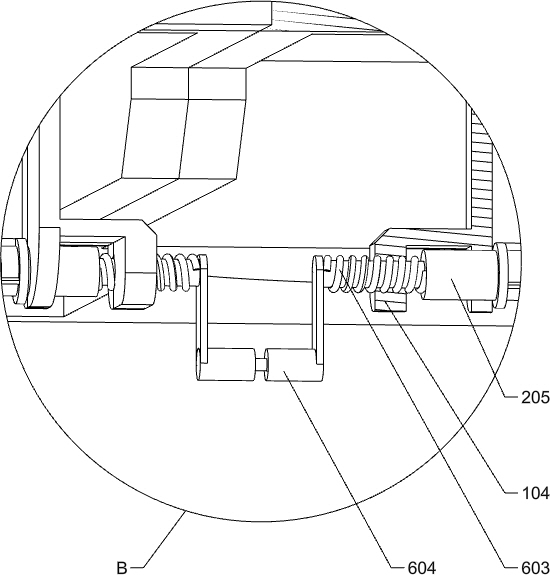

[0037] On the basis of Example 1, as Figure 2-Figure 4 As shown, the seed transport mechanism includes a first fixing rod 201, and there are two first fixing rods 201. The two first fixing rods 201 are welded to the left and right sides of the middle of the first fixing frame 104 respectively. Two sleeve rods 202 are rotatably connected to the rods 201. The four sleeve rods 202 and the power output end of the transfer case 102 are all driven by pulleys and belts. The rotating rod 203, the sleeve rods 202 on the opposite sides of the two first fixed rods 201 are respectively connected, and the adjacent first rotating rods 203 are driven by pulleys and belts, and the opposite sides of the two first rotating rods 203 are all keyed The first gear 204 is connected, and the two second fixing frames 106 are rotatably connected with spline rotating rods 205. The two spline rotating rods 205 are respectively located on the lower side of the adjacent first rotating rods 203. The oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com