Isocyanate derivative, preparation method and application thereof, and lubricating grease composition

A technology of isocyanate and derivatives, applied in lubricating compositions, thickeners, organic chemistry, etc., can solve problems such as improving the performance of lubricating grease compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

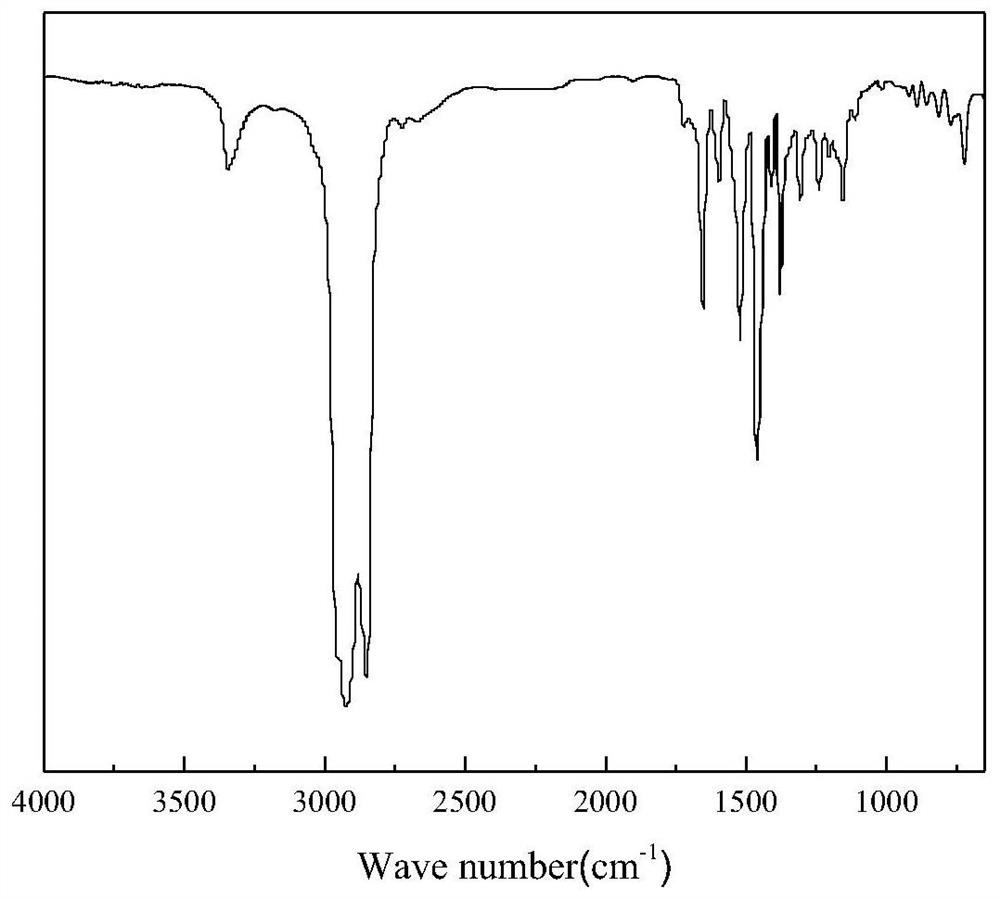

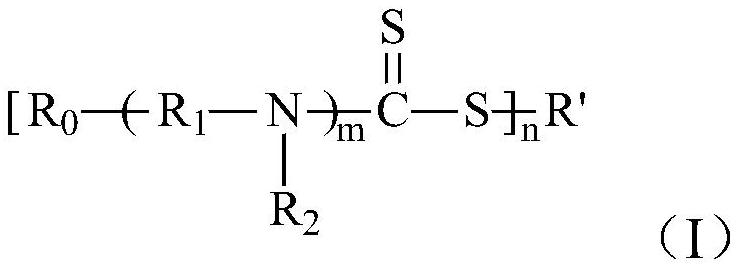

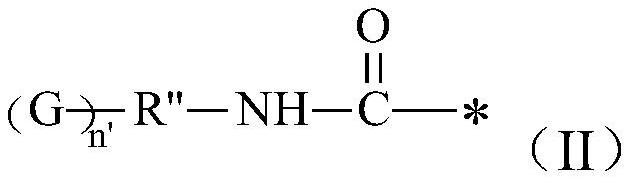

Image

Examples

Embodiment 1

[0098]Mix 4g n-butylamine, 4.38g sodium hydroxide solution with a mass concentration of 50%, 5g toluene and 5g isopropanol, slowly add 4.16g carbon disulfide dropwise within 1h, control the temperature at 30°C, then heat up to 65°C, slowly 2.33 g of dichloromethane was added, and the temperature was controlled at 60-65° C. to react for 2 h, then repeatedly washed with water, heated under reduced pressure to remove water and solvent, and filtered to remove sodium chloride to obtain 8.49 g of butyl dithiocarbamate for use.

[0099] Add 8.49g butyl dithiocarbamate to 30g 500N base oil, add 6.51g phenyl isocyanate to 30g 500N base oil to dissolve, slowly add to the butyl dithiocarbamate and 500N base oil. In the base oil mixture, the temperature was kept at 80 °C and the reaction was fully stirred for 1 h. Continue to heat up to 185° C., refine at a constant temperature for 15 minutes, cool and grind to obtain a grease composition.

[0100] The equation of the main reaction in th...

Embodiment 2

[0104] Mix 3.56g n-butylamine, 3.90g sodium hydroxide solution with a mass concentration of 50%, 5g toluene and 5g isopropanol, slowly add 3.71g carbon disulfide dropwise within 1h, control the temperature at 30°C, and then heat up to 65°C, 2.07g of dichloromethane was slowly added, the temperature was controlled at 60-65°C and the reaction was performed for 2h, then repeatedly washed with water, heated under reduced pressure to remove water and solvent, and filtered to remove sodium chloride to obtain 7.55g of butyldithiocarbamate for use.

[0105] Add 7.55g butyl dithiocarbamate to 30g 500N base oil, add 7.45g p-chlorophenyl isocyanate to 30g 500N base oil to dissolve, then slowly add to the butyl dithiocarbamate In the mixture with 500N base oil, the temperature was kept at 80°C and the reaction was fully stirred for 1h. Continue to heat up to 185° C., keep the temperature for 15 minutes, cool and grind to obtain a grease composition.

[0106] The equation of the main reac...

Embodiment 3

[0109] Mix 7.40g octadecyl primary amine, 2.20g sodium hydroxide solution with a mass concentration of 50%, 5g toluene, and 5g isopropanol, slowly add 2.09g carbon disulfide dropwise within 1h, control the temperature at 30°C, and then heat up to 65°C, slowly add 1.17g of dichloromethane, control the temperature at 60-65°C and react for 2 hours, then repeatedly wash with water, heat under reduced pressure to remove water and solvent, and filter to remove sodium chloride to obtain 9.66g of octadecyldithioamino Formate reserve.

[0110] Add 9.66g of octadecyl dithiocarbamate to 30g of 500N base oil, add 5.34g of phenyl isocyanate to 30g of 500N base oil to dissolve, then slowly add to the octadecyl dithiocarbamate In the mixture of acid ester and 500N base oil, the temperature was kept at 80 °C and the reaction was fully stirred for 1 h. Continue to heat up to 185° C., keep the temperature for 15 minutes, cool and grind to obtain a grease composition.

[0111] The equation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com