Transmission belt, use of transmission belt of this type as poly V-belt, and method for producing transmission belt of this type

A technology for transmission belts and V-ribbed belts, which is applied in the field of transmission belts, can solve problems such as defects, short service life, and poor cutability of transmission belts, and achieve the effects of improved performance, long service life, and increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

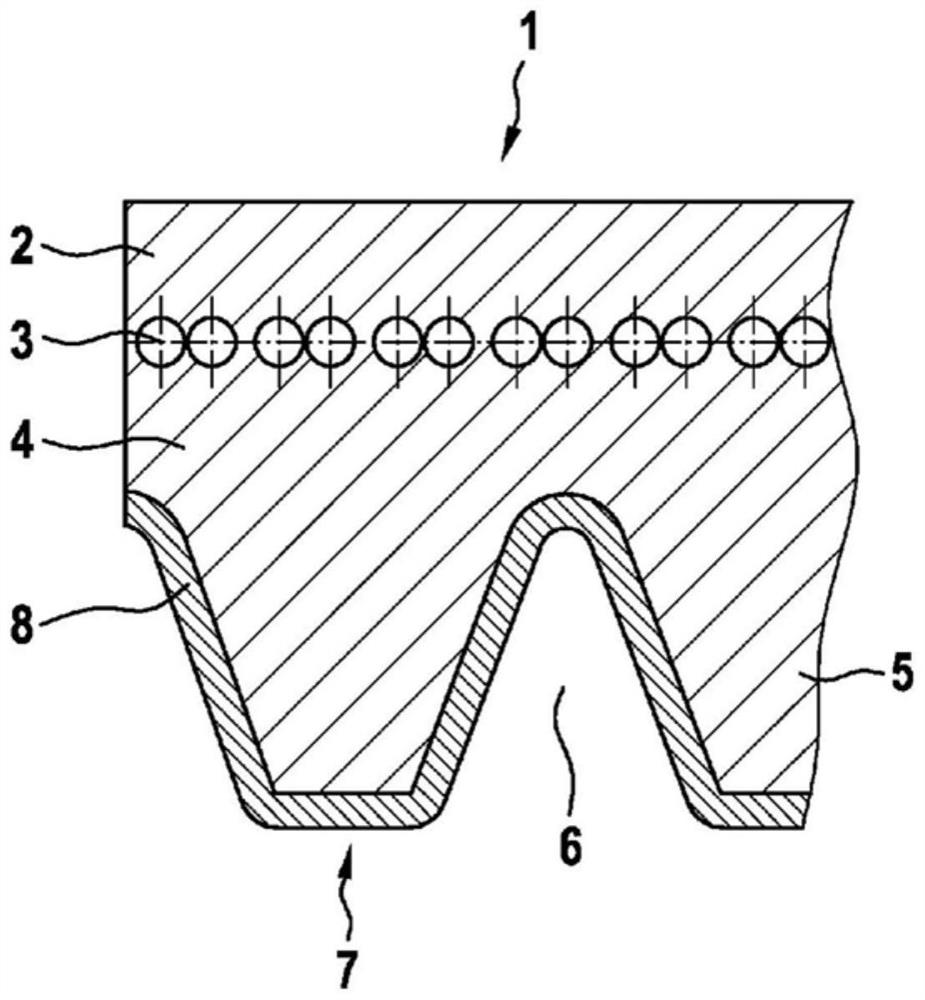

[0045] figure 1 A partial section of a drive belt is shown, the main body of which is formed by the outer layer 2 and the bottom structural hybrid 4 . Extending between the top layer 2 and the bottom structural hybrid 4 is a layer of tension threads consisting of a plurality of tension threads 3 . The tension wires 3 are preferably arranged parallel to each other. It is also conceivable that the tension wires 3 are arranged offset relative to each other.

[0046] like figure 1 The drive belt 1 shown is in the form of a V-ribbed belt. For this purpose, the base structure 4 has a plurality of ribs 5 arranged parallel to each other, which are delimited by grooves 6 to each other. The side of the bottom structural hybrid 3 opposite the tension wires 3 or the top layer 2 forms a force transmission surface 7 extending through the ribs 5 and through the grooves 6 .

[0047] The force transmission surface 7 may have a coating 8 . The coating 8 may be a flocked coating, in partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Torsion | aaaaa | aaaaa |

| Torsion | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com