Finish rolling strip steel deviation detection system and method based on binocular linear array camera

A line scan camera, strip deviation technology, applied in the field of strip rolling, can solve the problems of strip wedge index fluctuation, no effective monitoring means, strip surface scratches, etc., to reduce data transmission delay, improve Communication stability, ease of use and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

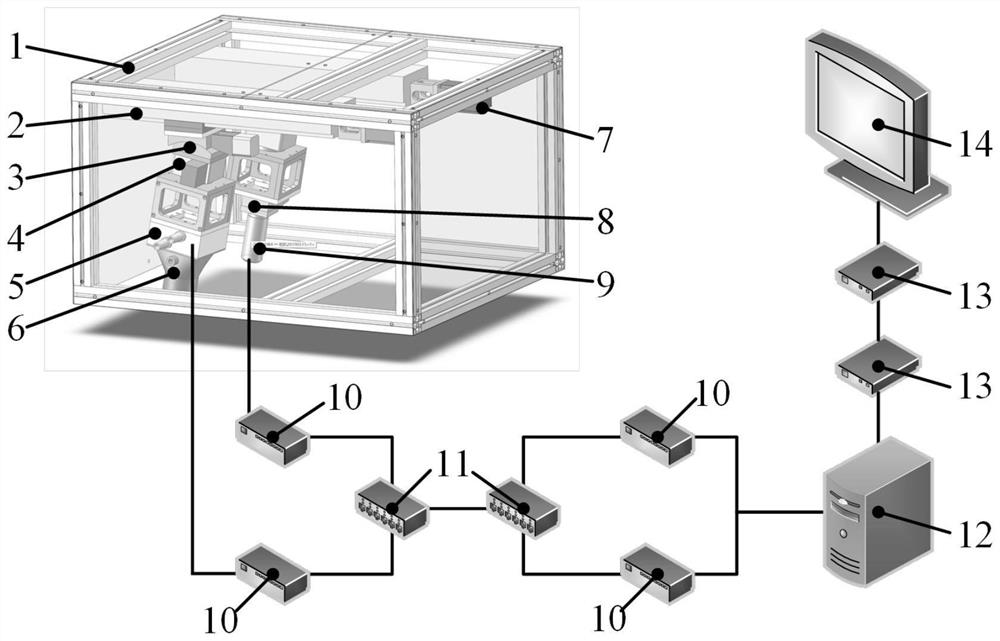

[0057] An embodiment of the present invention provides a system for detecting the deviation of a finishing strip steel based on a binocular line scan camera, comprising: a camera mounting bracket (1), two line scan cameras (8) and lenses (9), and two sets of cameras Adjustment device (2, 3, 4), four photoelectric converters (10), image processing server (12), optical fiber junction box (11), KVM switch (Keyboard Video Mouse, KVM) (13) and terminal a display (14); wherein,

[0058] The camera adjusting devices (2, 3, 4) are fixedly mounted on the camera mounting bracket (1), and are used for adjusting the spatial pose of the line scan camera (8);

[0059] Two line scan cameras (8) are fixed between the two finishing mills through the camera m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com