Plastic pipe chamfering device

A chamfering device and plastic pipe technology, which is applied in the field of pipe processing, can solve the problems of low efficiency, manpower consumption, and high error rate, and achieve the effects of high chamfering efficiency, stable clamping, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

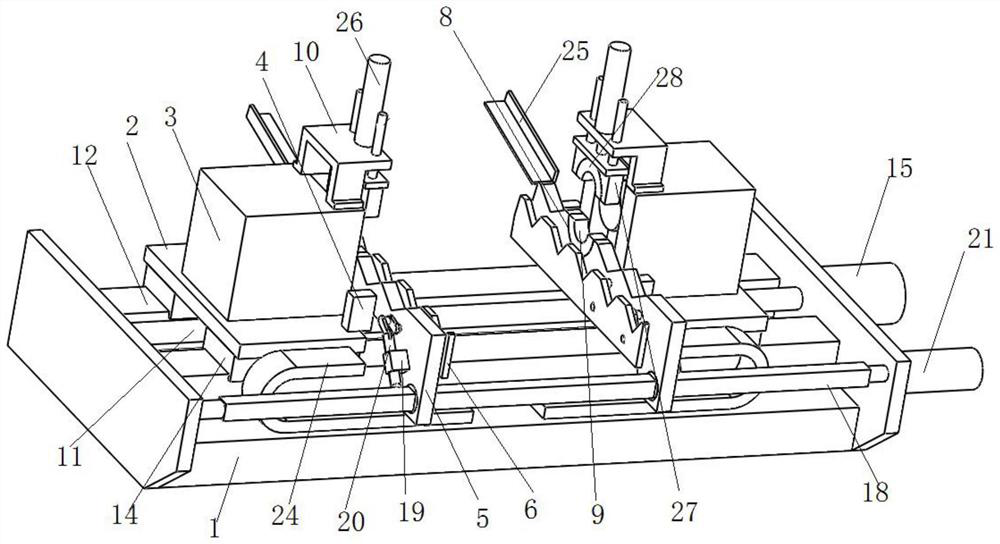

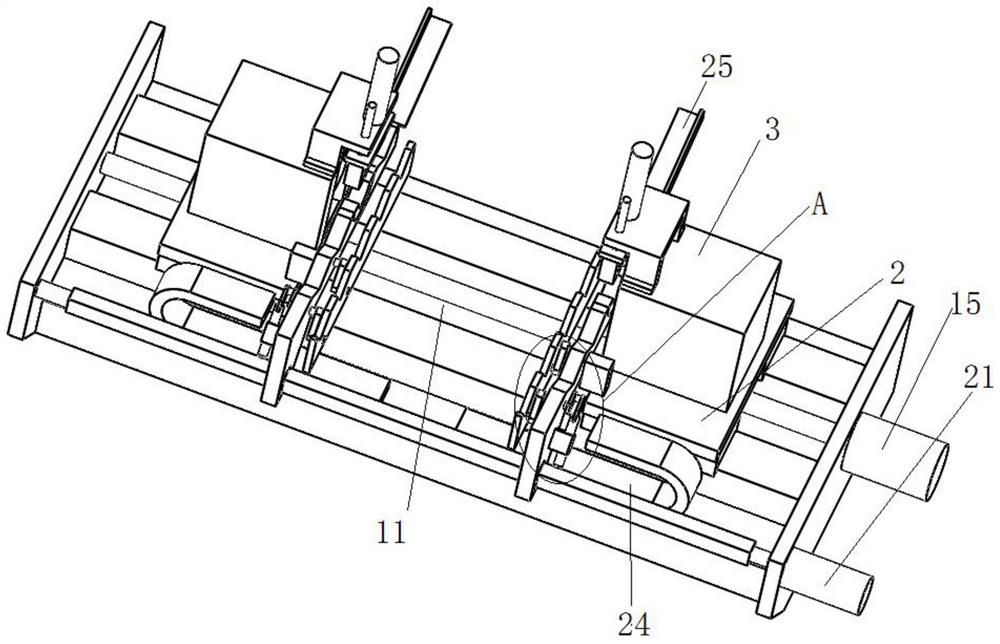

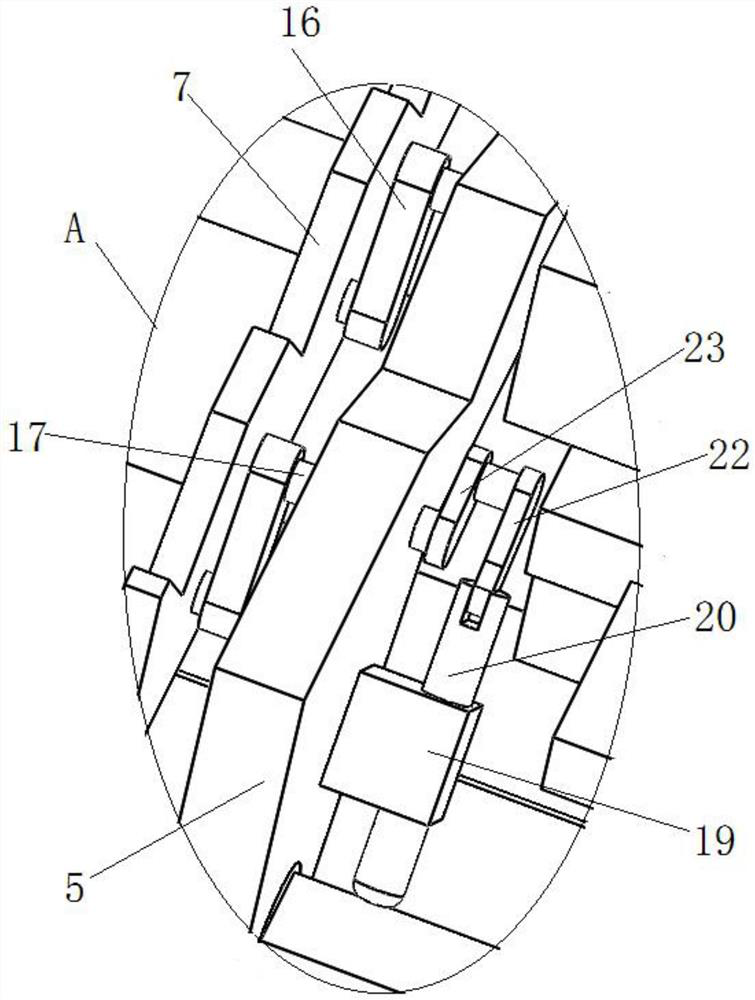

[0021] When implemented, such as Figure 1-4 As shown in the figure, a plastic pipe chamfering device includes a workbench 1, on which a sliding table 2 is symmetrically and slidably provided, and the sliding table 2 is fixedly installed with a chamfering device for chamfering both ends of a plastic pipe. The angle machine body 3, one side of the cutter head of the chamfer machine body 3 is fixedly installed with a fixing plate 5 for placing the plastic pipe through the mounting block 4, and the fixing plate 5 is rotated by a linear reciprocating mechanism. The transfer plate 6 of the pipe, the fixed plate 5 and the transfer plate 6 are provided with placement grooves 7, and the fixed plate 5 is provided with a clamping groove 8 corresponding to the cutter head of the chamfering machine body 3, so A clamping block 9 is detachably installed in the clamping gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com