Product automatic feeding and discharging clip, detection system and detection method

A technology for automatic loading and unloading of materials and products, applied in the direction of transportation and packaging, conveyor objects, sorting, etc., can solve problems such as falling, easy-to-collision products, and easy-to-collision problems, to avoid product damage, high degree of automation, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

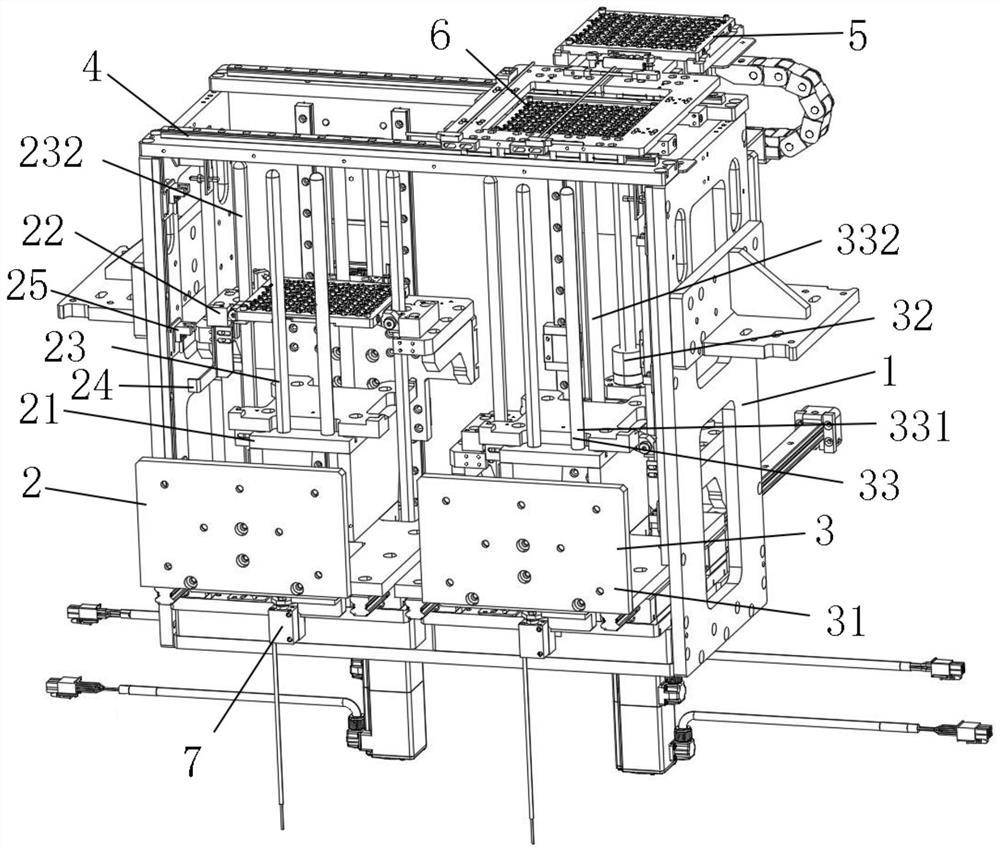

[0082] like Figure 1-Figure 7 As shown in the figure, an automatic loading and unloading magazine for products, which realizes loading and unloading of products by moving a feeding tray, includes a chassis 1, and a feeding device 2 and a feeding device 3 arranged side by side are arranged in the chassis. A running device 4 is arranged above the device and the unloading device, and a feeding device 5 is arranged on one side of the running device;

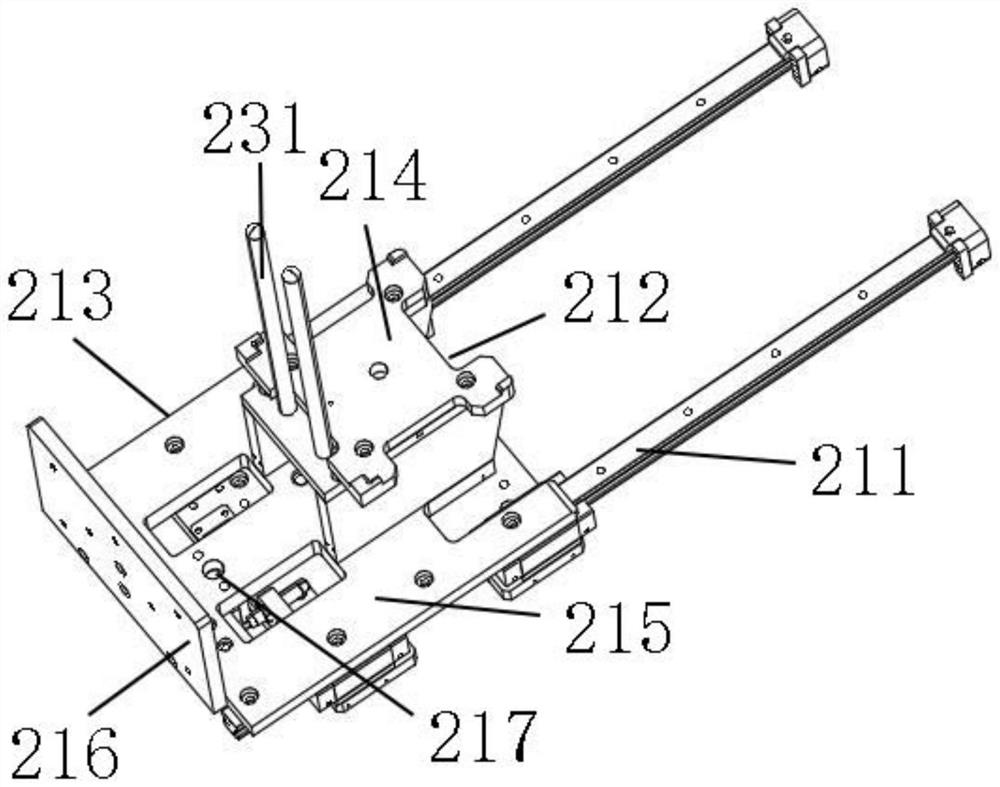

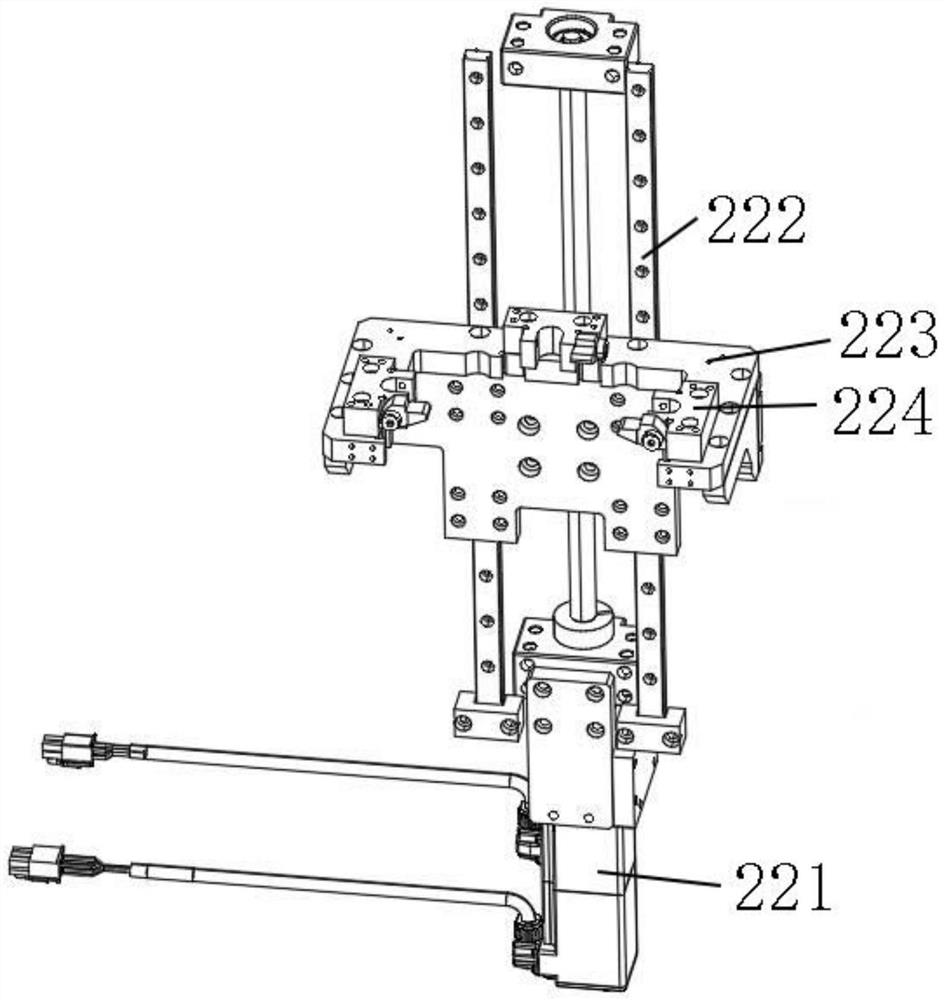

[0083] The loading device includes a loading bin 21, a loading carrying device 22 and a first guiding device 23, and the loading bin is located below the loading carrying device and moves horizontally relative to the chassis; The loading carrying device performs vertical reciprocating motion relative to the chassis between the loading bin and the operating device, so as to move the tray on the loading bin to a position close to the running device; The first guide device is located around the material tray and guides the vertical re...

Embodiment 2

[0120] This embodiment is carried out on the basis of the above-mentioned first embodiment, and the same points as the above-mentioned embodiment will not be repeated.

[0121] This embodiment mainly introduces a detection system related to the first embodiment, including detection equipment and the automatic product loading and unloading magazine as described in the first embodiment, the detection equipment is located in the operation device of the automatic product loading and unloading magazine Above, the detection equipment is used to detect the feeding tray in the operation device. If the detection results of the products in the feeding tray are all qualified, it will be moved to the feeding device for feeding; if the detection result of the product in the feeding tray is not The qualified ones are moved to the feeding device for feeding. The detection system further includes a control system, the control system includes a data receiving module, a data processing module a...

Embodiment 3

[0123] This embodiment is carried out on the basis of the above-mentioned second embodiment, and the same points as the above-mentioned embodiment will not be repeated.

[0124] This embodiment mainly introduces a detection method that this application also claims to protect, using the detection system as described in the second embodiment, and the specific steps are as follows:

[0125] S1. Move the feeding bin to the direction away from the chassis and place the trays in the feeding bin for stacking. After the stacking is completed, the feeding bin moves in the direction close to the chassis until it is located in the feeding bin. below the loading carrier;

[0126] S2. The loading and carrying device moves to the bottom of the lowermost material tray and drives the stacked material trays to move in a direction close to the running device;

[0127] S3. When the uppermost material tray moves to the range that can be clamped by the operation tray clamping mechanism, the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com