Optical film, method for producing same, polarizing plate, and display device

A manufacturing method and technology of optical films, which are applied in the directions of optics, polarizing elements, lighting devices, etc., to achieve the effects of sufficient film thickness, good adhesion and thin film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0316] The present invention will be specifically described below with reference to Examples, but the present invention is not limited to these Examples. In addition, although the representation of "part" or "%" is used in an Example, unless otherwise indicated, "mass part" or "mass %" are represented.

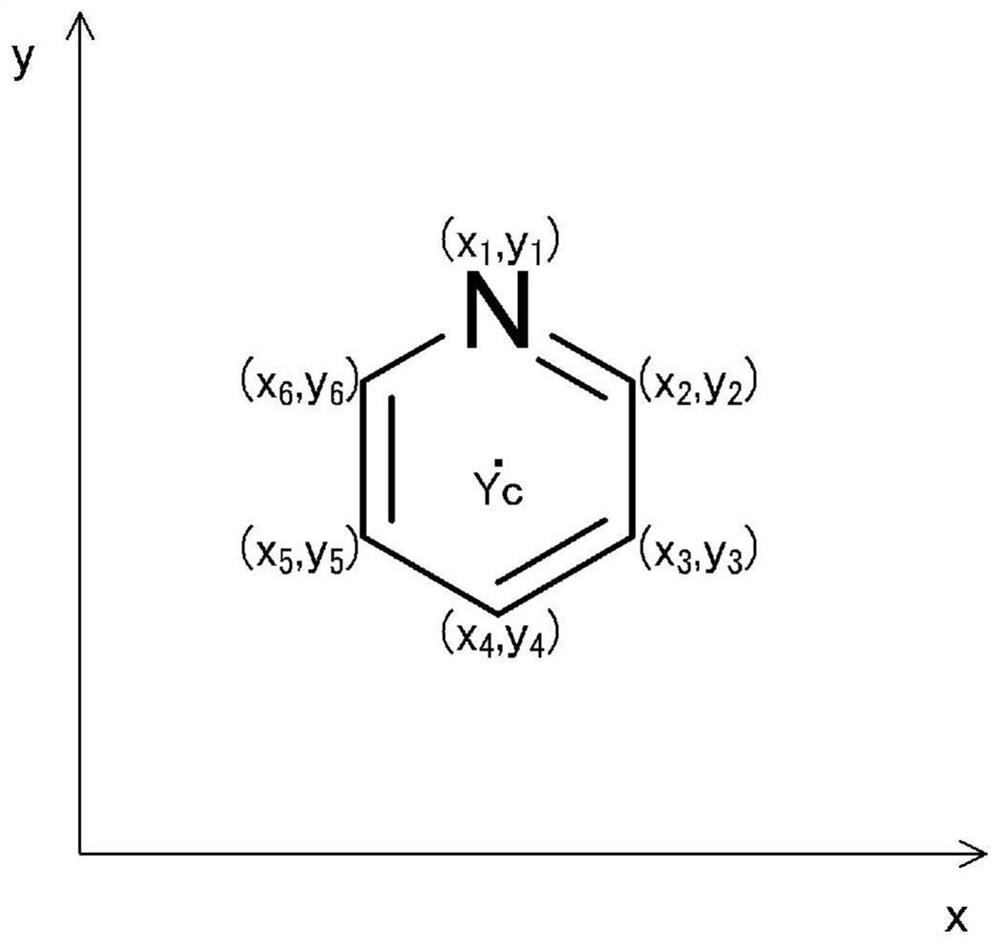

[0317] [Optical film]

[0318] 1. The material of the optical film

[0319] (1) Cycloolefin resin

[0320] As the cycloolefin resin having a polar group, a cycloolefin resin A composed of a unit having a structure represented by the following formula (I) was used (in the formula (I), R is CH 3 ). In addition, as the cycloolefin resin having no polar group, the cycloolefin resin B composed of a unit having a structure in which the group represented by COOR in the following formula (I) was substituted with a hydrogen atom was used.

[0321] [hua 5]

[0322] Formula (I)

[0323]

[0324] (2) Additives

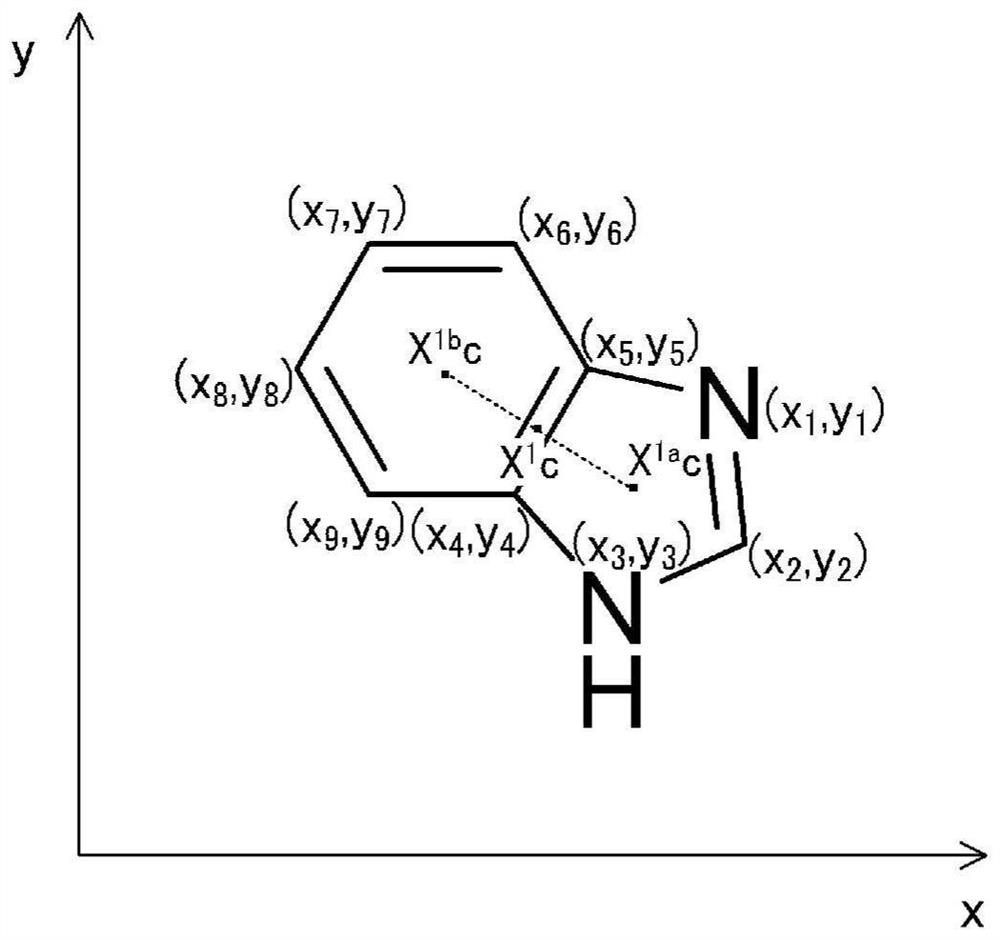

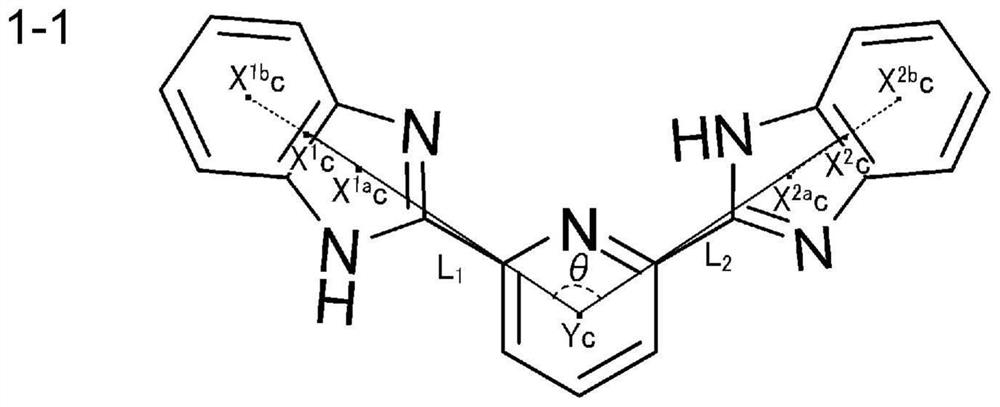

[0325] (2-1) Compound (1)

[0326] As compound (1), compounds 1-1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com