Winding device and winding method

A winding device and needle rolling technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problems of cell misalignment, complex structure, and affecting the quality of the cell, so as to improve work efficiency , The effect of improving the winding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

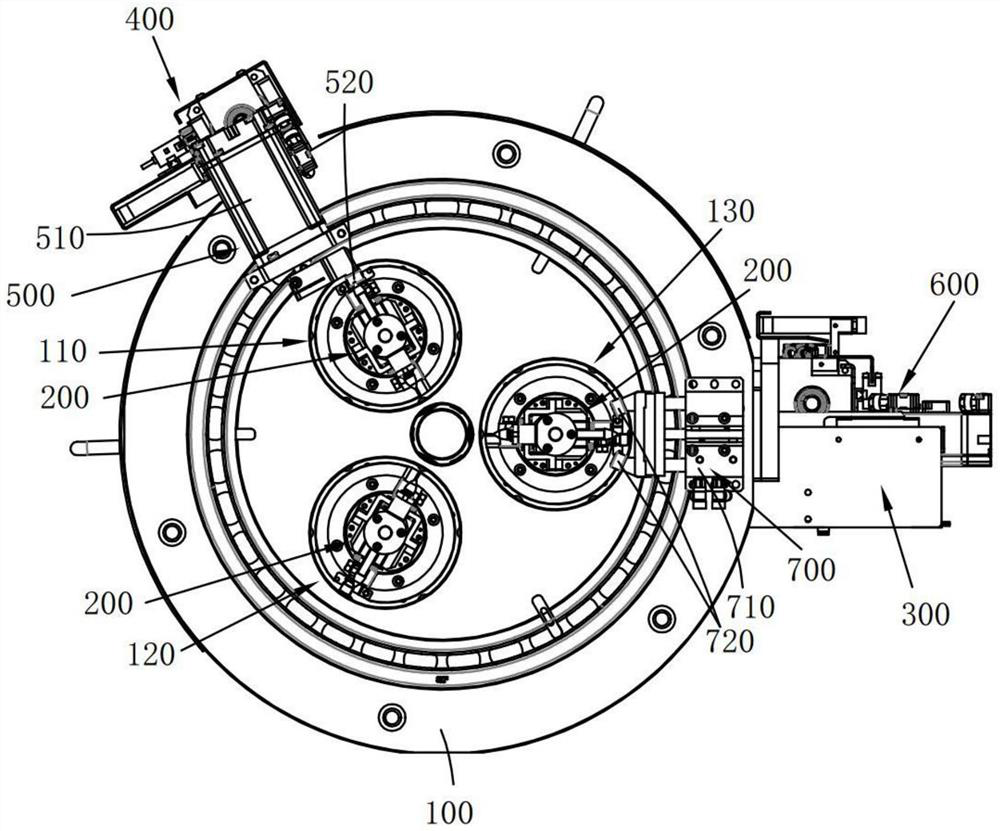

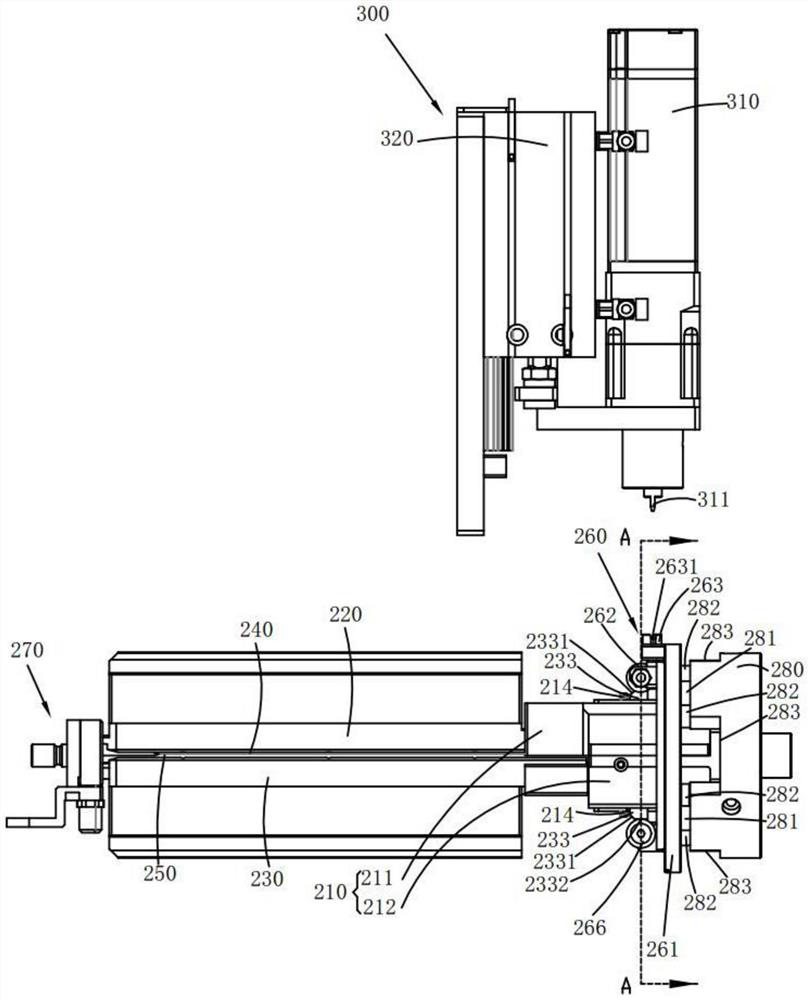

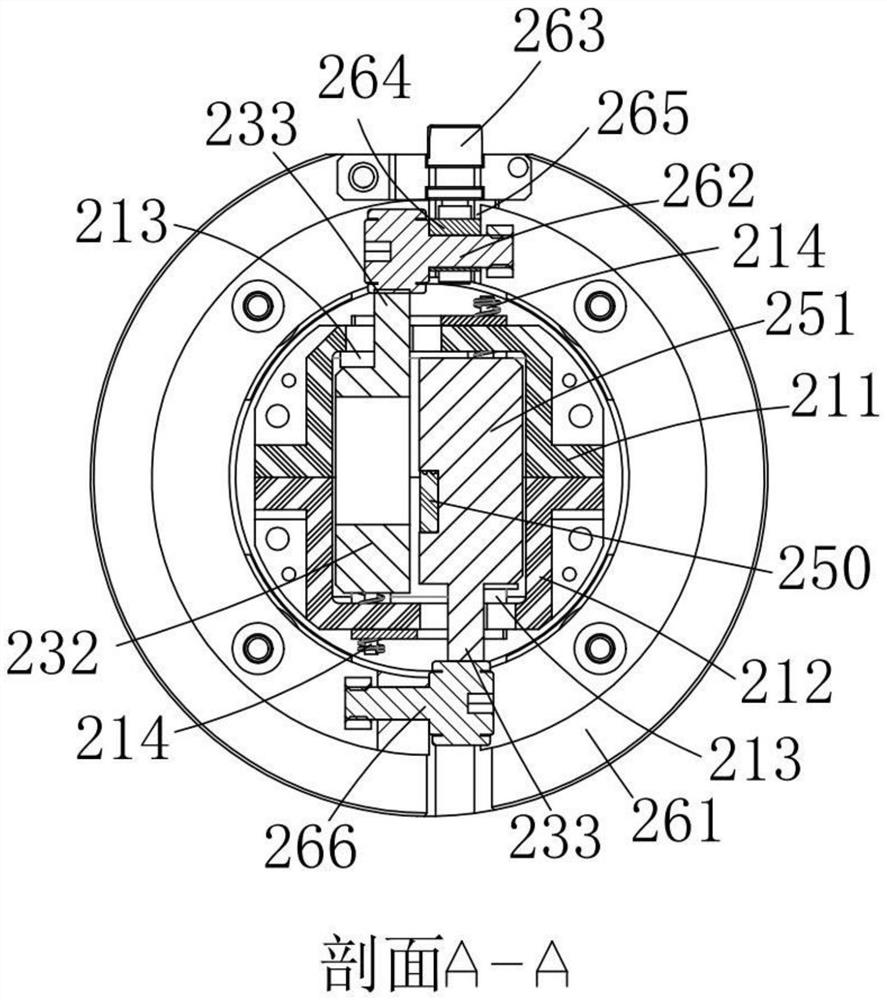

[0030] like figure 1 , figure 2 As shown, the winding device in this embodiment includes a turret 100 that rotates around an axis, and three stations are evenly arranged on the circumference of the turret 100 with the axis as the center, namely the winding station 110 and the gluing station 120 And the blanking station 130, the angle between each station is 120 degrees. Each station is provided with a needle winding mechanism 200. When the turret 100 rotates around its axis, it can drive the needle winding mechanism 200 to switch positions in sequence between different stations, so as to complete the winding, gluing, and unloading of the cell. operate. The needle winding mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com