Absolute value displacement measuring system of cubic press

A six-sided top press and displacement measurement technology, which is applied to measuring devices and instruments, can solve problems such as increased synthesis costs, low precision, and position detection errors of working cylinders, and achieve improved production efficiency, fast dynamic response, and stable margins. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

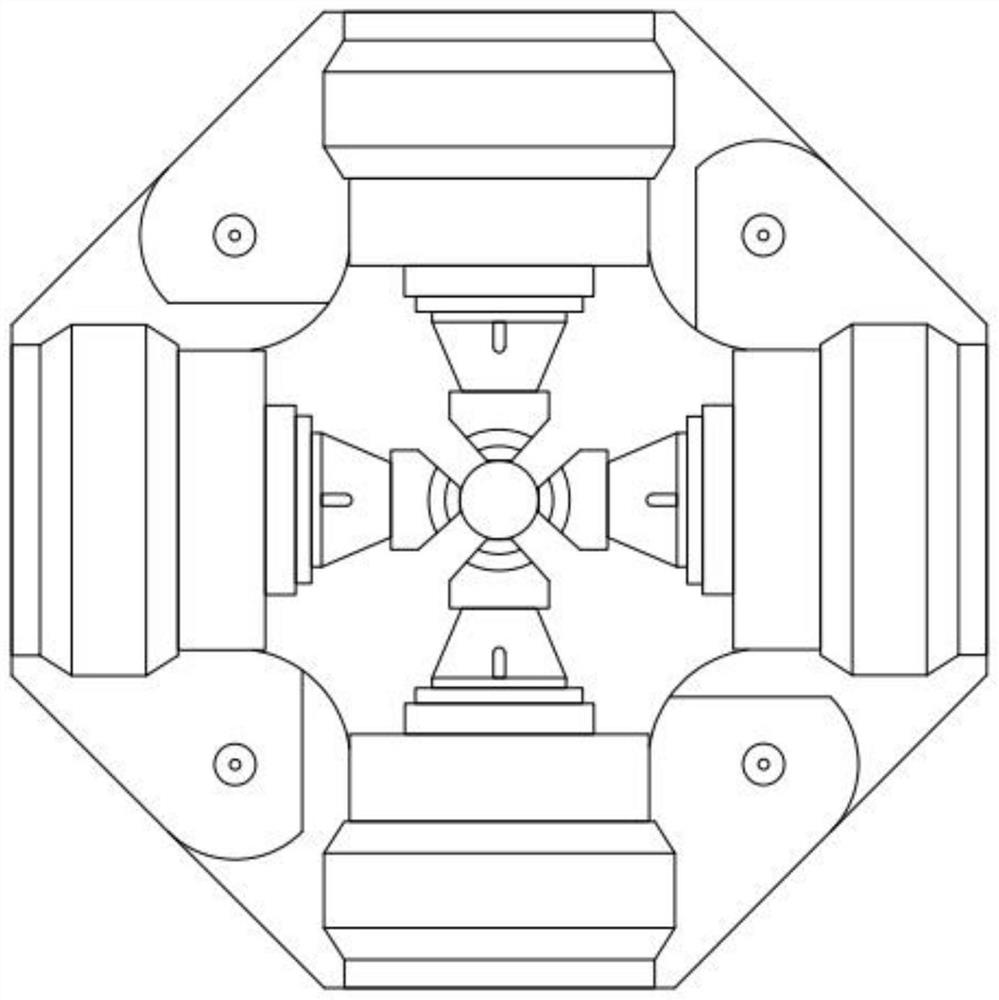

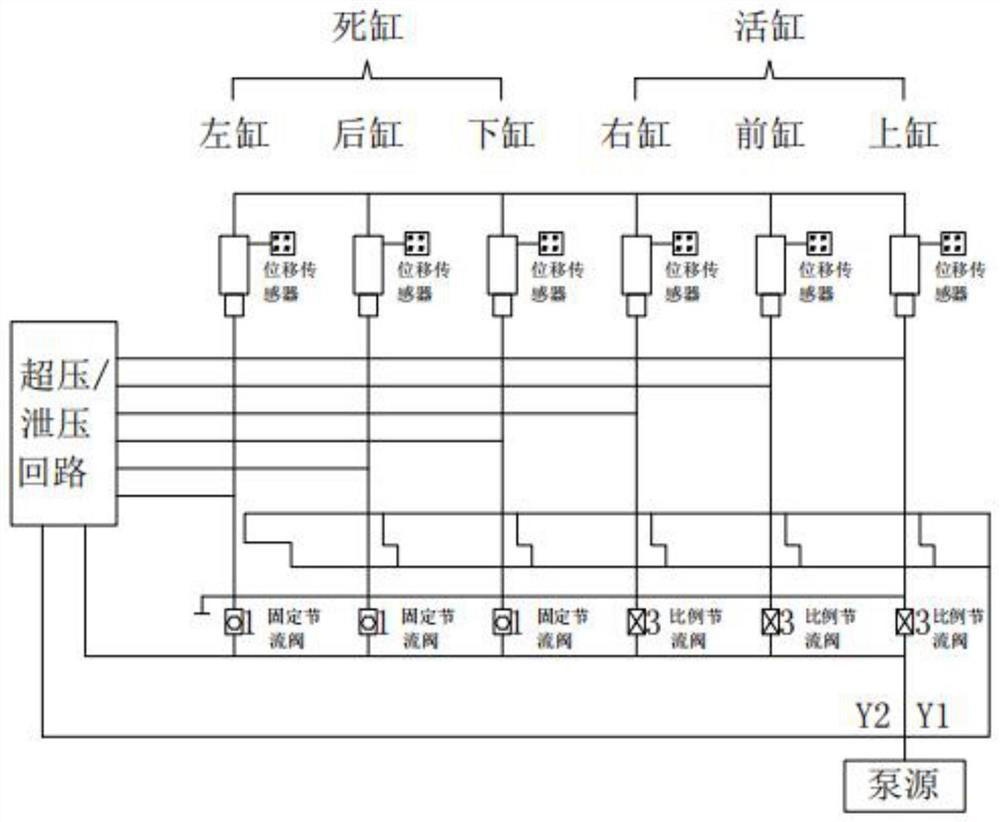

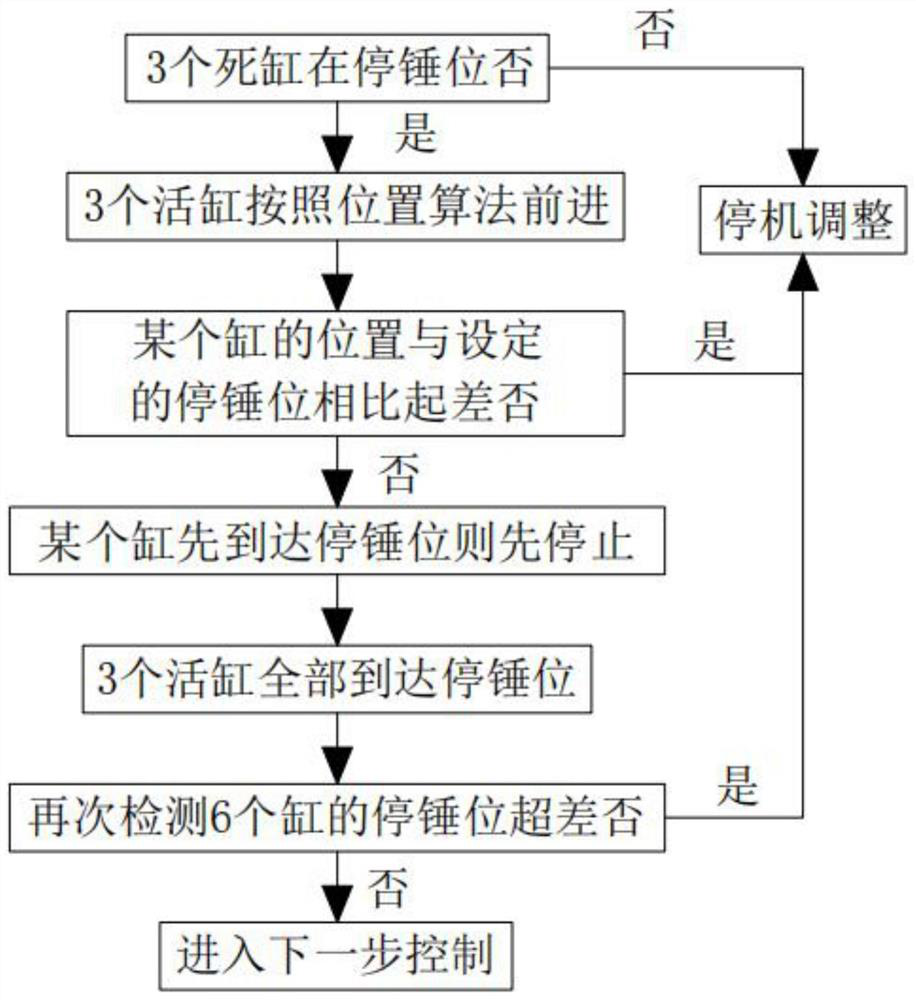

[0020] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 It is the structural schematic diagram of the six-sided top press of the present invention; figure 2 is the control strategy diagram of the present invention; image 3 It is a schematic diagram of the position control principle of the hammer stop position of the present invention. The absolute value displacement measurement system of a six-sided top press includes: a six-sided top press, computer equipment and electro-hydraulic control equipment, the six-sided top press includes 6 cylinders, and the 6 cylinders include three dead cylinders and three Live cylinder, the three dead cylinders are the left cylinder, the rear cylinder and the lower cylinder respectively, and the three live cylinders are the right cylinder, the front cylinder and the upper cylinder respectively;

[0021] The three dead cylinders are connected by a fixed throttle valve, and the three live cylinders are connected by a proporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com