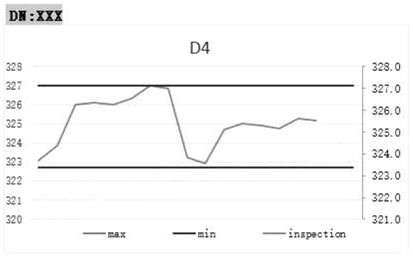

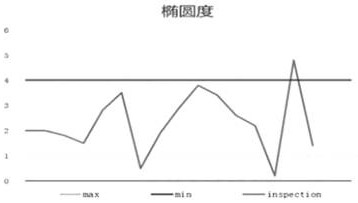

Device and method for detecting ovality and diameter of large-diameter spheroidal graphite cast pipe

A detection device and detection method technology, applied in the direction of measurement device, optical device, instrument, etc., can solve the problems of limited diameter range, unable to complete the detection task, unable to cover cast pipe products, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

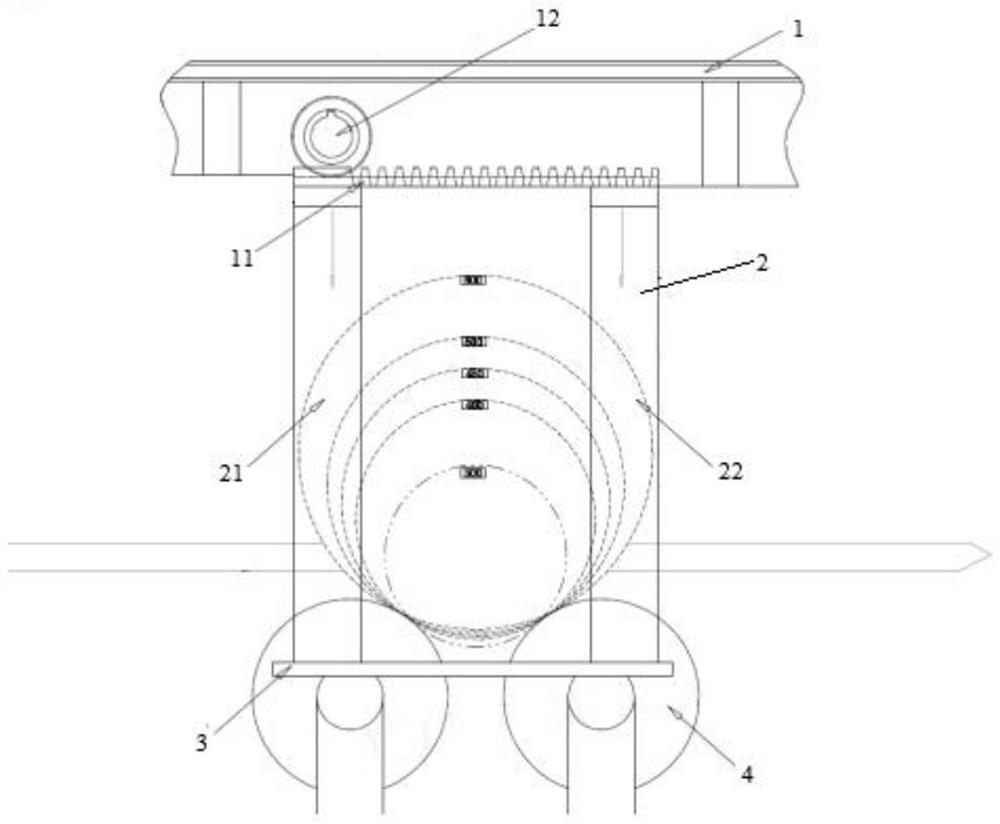

[0038] from Figure 1-2 It can be seen that a device for detecting the ovality and diameter of a large-diameter ductile cast pipe in this embodiment includes a fixing bracket 1 and a sensor assembly 2. The frame body of the fixing bracket 1 is equipped with a sensor assembly 2, and the sensor assembly 2 It consists of a first sensor 21 and a second sensor 22, and the first sensor 21 and the second sensor 22 are arranged in parallel and spaced apart;

[0039] The first sensor 21 is composed of a first transmitter 211 and a first receiver 212, and the second sensor 22 is composed of a second transmitter 221 and a second receiver 222. The first transmitter 211 and the second transmitter 221 are respectively installed in the On the fixed bracket 1, one side of the fixed bracket 1 is provided with slider guide rails 3 at intervals, the first receiver 212 and the second receiver 222 are respectively installed on the slider guide rail 3, and the ductile iron pipe is placed on the fir...

Embodiment 2

[0058] from image 3 It can be seen that a large-diameter nodular cast pipe ovality and diameter detection device includes a fixed bracket 1 and a sensor assembly 2, wherein the sensor assembly 2 is provided with two groups as required, and four groups of LED or laser transmission type are used. The sensors are arranged in parallel horizontally, and the detection range can be expanded on the basis of Example 1, covering a variety of ductile cast pipe models, and the detection task can be completed through the background software data collection, calculation, and judgment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com