Hydrogenation gun

A valve body and interface technology, applied in the field of hydrogen refueling guns, can solve problems such as long delivery period, affecting the development of hydrogen refueling stations, and lack of maintenance capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments, but the following embodiments are only preferred embodiments of the present invention, not all. Based on the examples in the implementation manner, other examples obtained by those skilled in the art without creative work shall fall within the protection scope of the present invention. The experimental methods in the following examples are conventional methods unless otherwise specified, and the materials, reagents, etc. used in the following examples can be obtained from commercial sources unless otherwise specified.

[0023] Example:

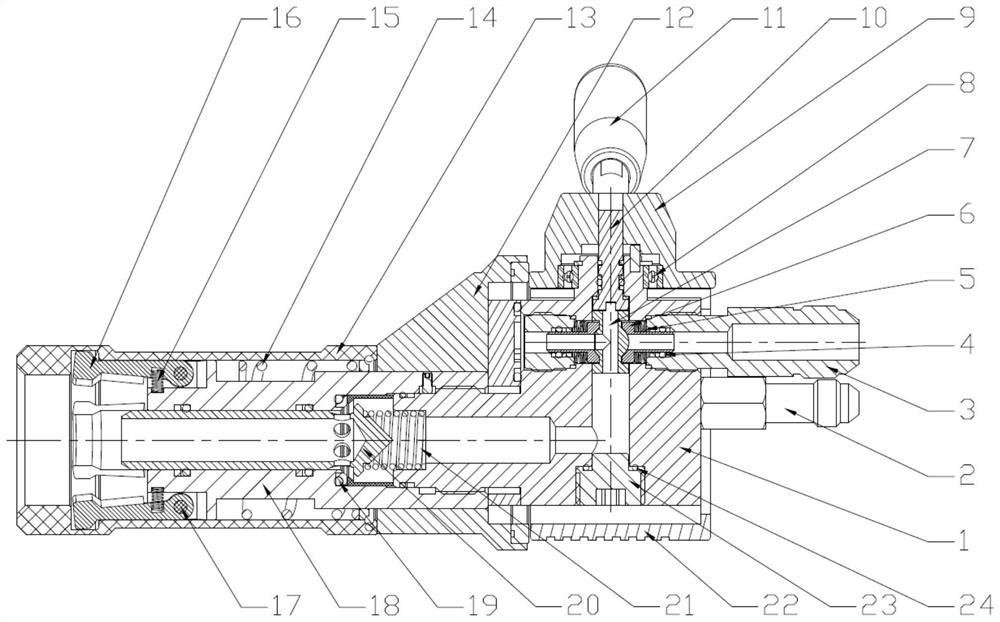

[0024] like Figure 1-4 As shown in the figure, a hydrogenation gun, the valve body 1 is provided with a return air port 2 and an air inlet port 3, the outer wall of the valve body 1 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com