Steam pipeline butterfly valve with pressure relief function

A technology of steam pipes and butterfly valves, which is applied in the field of butterfly valves, can solve problems such as time-consuming maintenance, reduced work efficiency, and increased air pressure, and achieves the effects of avoiding pipeline damage, saving costs and time, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

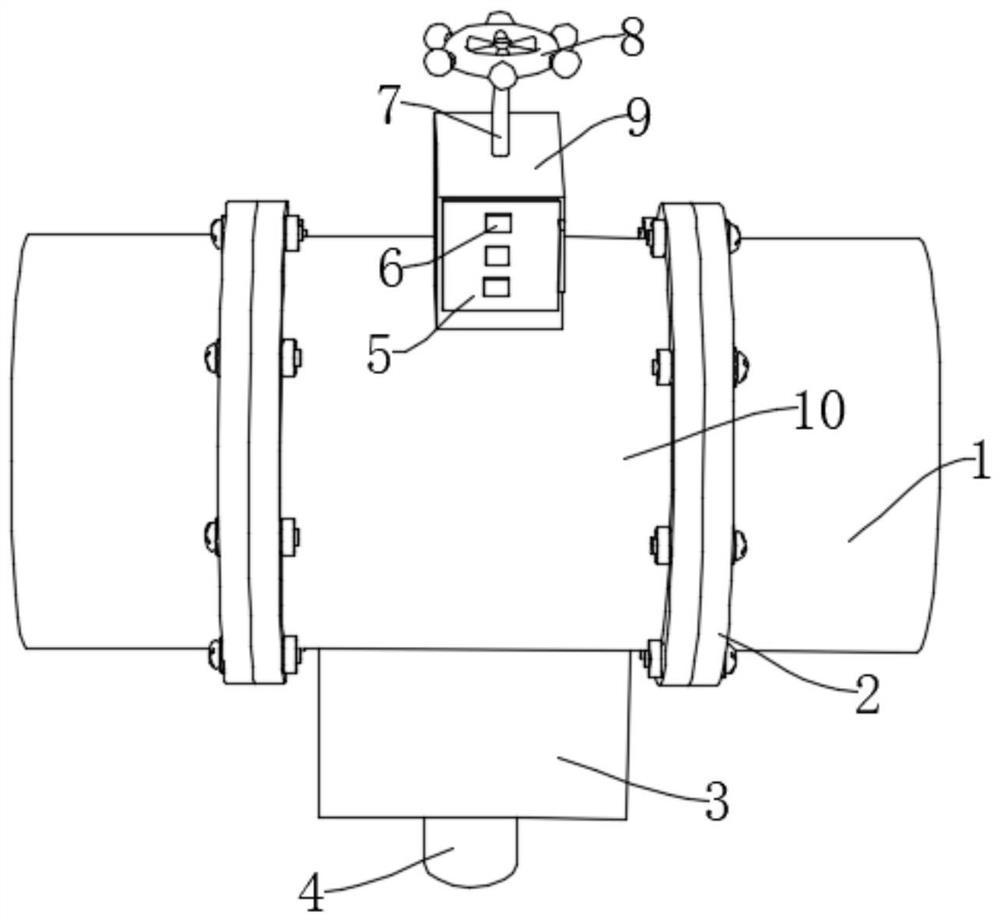

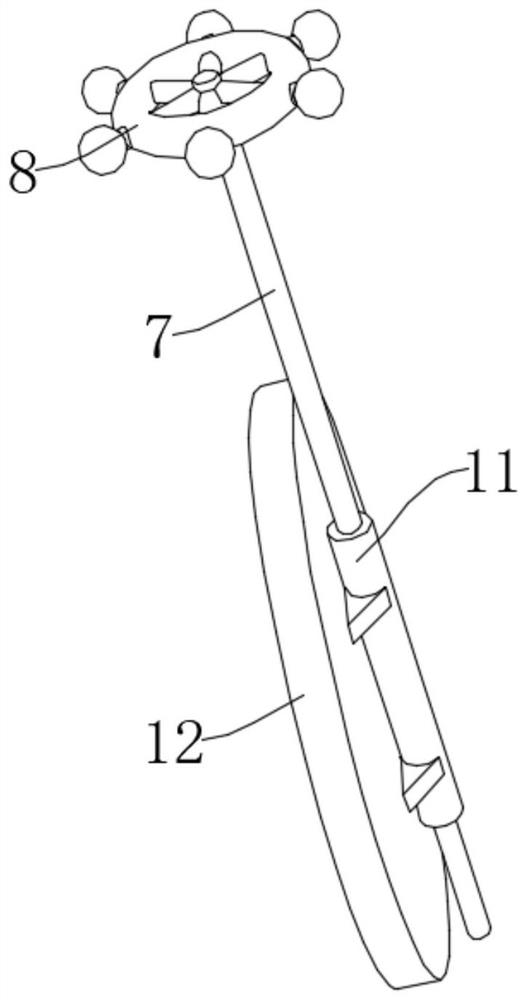

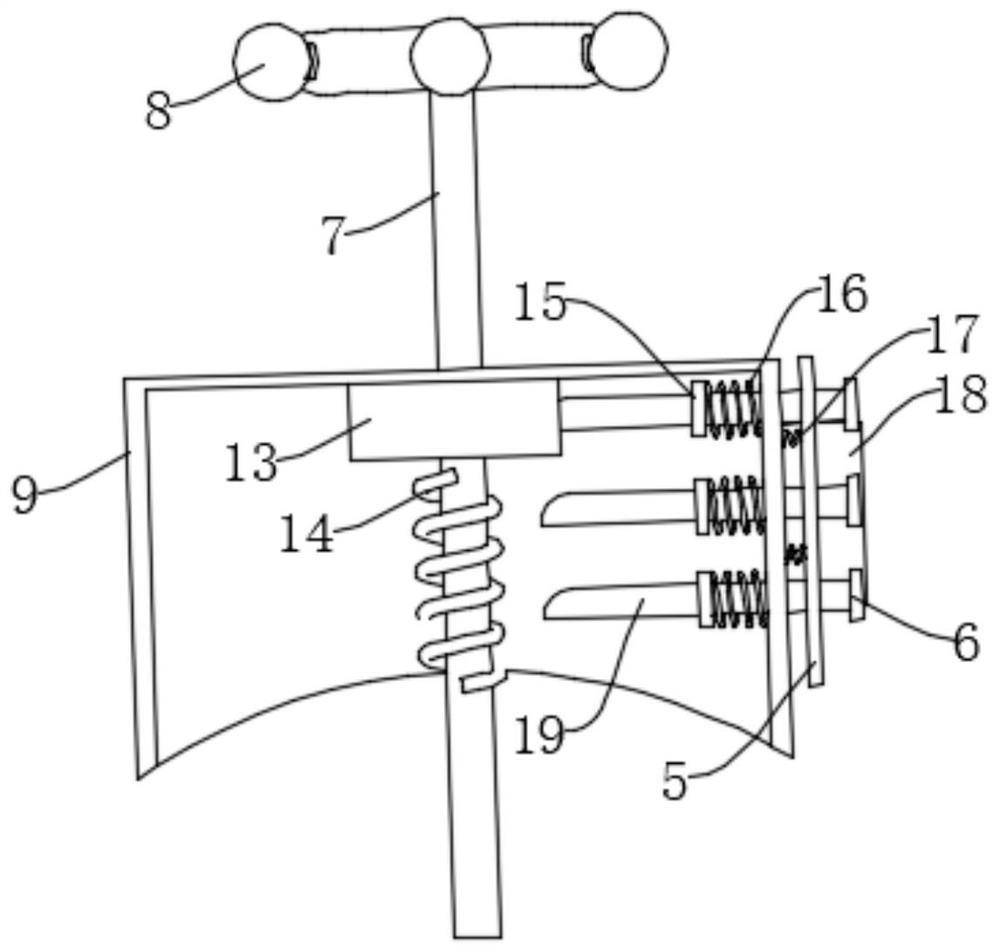

[0031] refer to Figure 1-Figure 7 , a steam pipeline butterfly valve with a pressure relief function, comprising a butterfly valve body 10, both ends of the butterfly valve body 10 are fixedly connected with a connecting pipe 1, the top of the butterfly valve body 10 is fixedly connected with a second rectangular box 9, the second rectangular box The inner wall of 9 is slidably connected with a sliding block 13, the inner wall of the sliding block 13 rotates through a rotating shaft 7, the top of the rotating shaft 7 penetrates the second rectangular box 9 and is fixedly connected with a handle 8, and the outer wall of the rotating shaft 7 is slidably provided with a fixed cylinder 11, One side of the fixing cylinder 11 is fixedly connected with the valve flap 12 used in cooperation with the butterfly valve body 10, and one side of the second rectangular box 9 is provided with a fixing component for fixing the sliding block 13;

[0032] The bottom of the butterfly valve body ...

Embodiment 2

[0035] refer to Figure 1-Figure 7 , a steam pipeline butterfly valve with a pressure relief function, comprising a butterfly valve body 10, both ends of the butterfly valve body 10 are fixedly connected with a connecting pipe 1, the top of the butterfly valve body 10 is fixedly connected with a second rectangular box 9, the second rectangular box The inner wall of 9 is slidably connected with a sliding block 13, the inner wall of the sliding block 13 rotates through a rotating shaft 7, the top of the rotating shaft 7 penetrates the second rectangular box 9 and is fixedly connected with a handle 8, and the outer wall of the rotating shaft 7 is slidably provided with a fixed cylinder 11, One side of the fixed cylinder 11 is fixedly connected with the valve flap 12 used in conjunction with the butterfly valve body 10 , one side of the second rectangular box 9 is provided with a fixed component for fixing the sliding block 13 , and the fixed component includes a sliding through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com