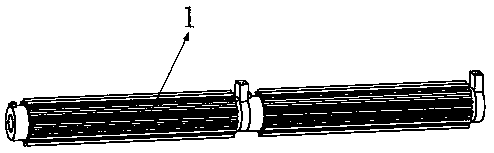

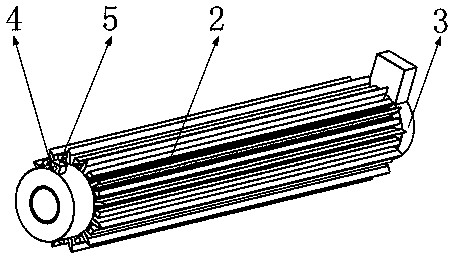

Engineering pipeline

A kind of pipeline and engineering technology, applied in the direction of pipeline protection, pipeline damage/wear prevention, pipe/pipe joint/pipe fittings, etc., can solve the problems of pipeline breakage, health impact, and the pipeline is hit by foreign objects, and achieve the effect of preventing pipeline damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

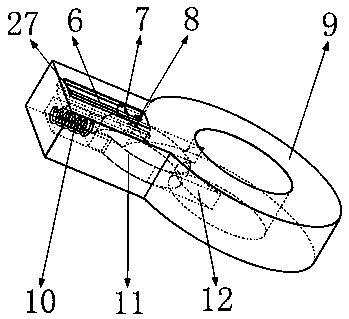

[0045] Specific implementation: when people use the pipeline designed by the present invention; when the pipeline is hit and the impact point is located on the anti-smashing tooth 19; under the action of the impact force, the anti-smashing tooth 19 will swing around the axis of the tooth rotation shaft 16; The swinging of the anti-smashing teeth 19 will drive the drive ring column 23 to rotate; the rotation of the driving ring column 23 will drive 13 anti-smashing teeth 19 to swing around the corresponding tooth shafts 16 respectively; During the swinging process, the overall pipeline will be driven downward; the soil around the pipeline will be rolled to the upper side of the pipeline; the soil passing through the upper side of the pipeline can buffer the impact force of the pipeline; the pipeline is protected; when two adjacent When the anti-smashing teeth 19 are hit; the impact force will extrude the extruding block 18; the extruding block 18 will move downward; the extrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com