Rotary crane device

A technology of slewing platform and slewing mechanism, which is applied in hoisting devices, cranes, hydroelectric power generation, etc. It can solve problems such as low hoisting accuracy and efficiency, large sloshing, and inability to ensure automatic and precise positioning of gates into slots, etc., to improve installation Convenience, easy installation, and the effect of improving hoisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

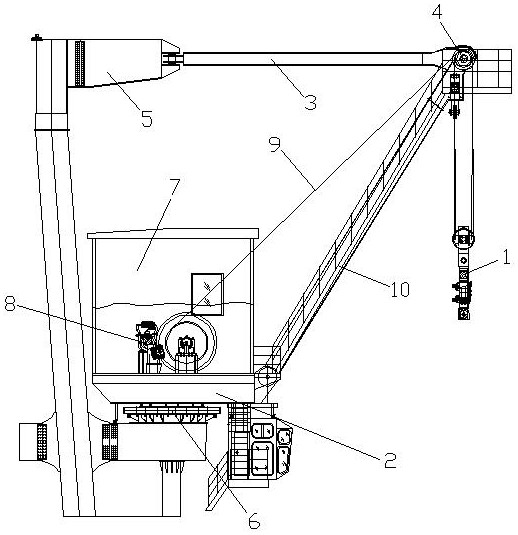

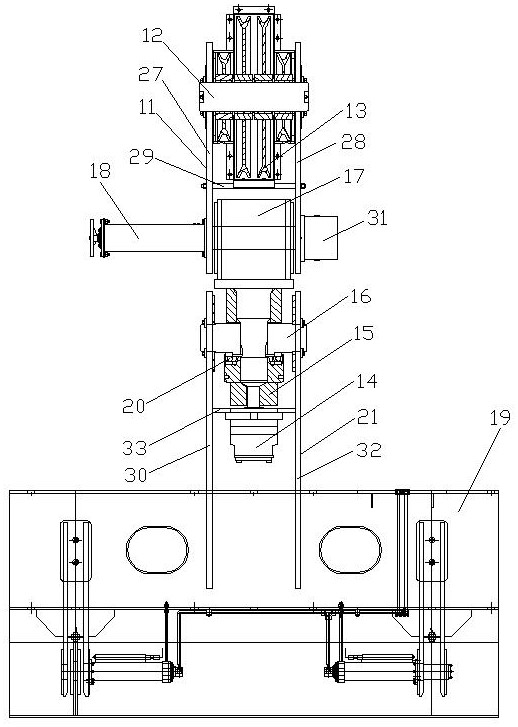

[0031] see figure 1 and figure 2 , a slewing hoisting device, including a spreader 1, a slewing platform 2, a pull rod 3, a pulley block 4, a slewing mechanism 6 installed under the gantry 5 and a slewing machine room 7 installed on the slewing mechanism 6 through the slewing platform 2, the slewing machine room A hoisting mechanism 8 is installed in 7, a wire rope 9 is wound on the hoisting mechanism 8, a boom 10 is installed on the slewing machine room 7, the pulley block 4 is installed on the top of the boom 10, and one end of the pull rod 3 is hinged with the top of the gantry 5 , the other end of the pull rod 3 is hinged with the arm frame 10, and the hanger 1 includes an upper hanger 11, a pulley shaft 12, a movable pulley block 13, a pin 18, a lifting head 17, a lower hanger 21, a hook beam 16, a hanger The hook nut 15, the rotary drive member 14 and the grab beam 19, the movable pulley block 13 is installed on the upper hanger 11 through the pulley shaft 12, and the ...

Embodiment 2

[0034] see figure 1 and figure 2, a slewing hoisting device, including a spreader 1, a slewing platform 2, a pull rod 3, a pulley block 4, a slewing mechanism 6 installed under the gantry 5 and a slewing machine room 7 installed on the slewing mechanism 6 through the slewing platform 2, the slewing machine room A hoisting mechanism 8 is installed in 7, a wire rope 9 is wound on the hoisting mechanism 8, a boom 10 is installed on the slewing machine room 7, the pulley block 4 is installed on the top of the boom 10, and one end of the pull rod 3 is hinged with the top of the gantry 5 , the other end of the pull rod 3 is hinged with the arm frame 10, and the hanger 1 includes an upper hanger 11, a pulley shaft 12, a movable pulley block 13, a pin 18, a lifting head 17, a lower hanger 21, a hook beam 16, a hanger The hook nut 15, the rotary drive member 14 and the grab beam 19, the movable pulley block 13 is installed on the upper hanger 11 through the pulley shaft 12, and the m...

Embodiment 3

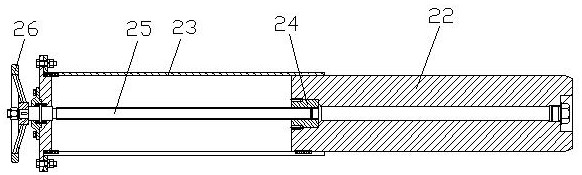

[0040] see Figure 1-Figure 3 , a slewing hoisting device, including a spreader 1, a slewing platform 2, a pull rod 3, a pulley block 4, a slewing mechanism 6 installed under the gantry 5 and a slewing machine room 7 installed on the slewing mechanism 6 through the slewing platform 2, the slewing machine room A hoisting mechanism 8 is installed in 7, a wire rope 9 is wound on the hoisting mechanism 8, a boom 10 is installed on the slewing machine room 7, the pulley block 4 is installed on the top of the boom 10, and one end of the pull rod 3 is hinged with the top of the gantry 5 , the other end of the pull rod 3 is hinged with the arm frame 10, and the hanger 1 includes an upper hanger 11, a pulley shaft 12, a movable pulley block 13, a pin 18, a lifting head 17, a lower hanger 21, a hook beam 16, a hanger The hook nut 15, the rotary drive member 14 and the grab beam 19, the movable pulley block 13 is installed on the upper hanger 11 through the pulley shaft 12, and the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com