Non-aqueous electrolyte and secondary battery

A non-aqueous electrolyte, non-aqueous technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as growth, high-temperature gas production resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] This embodiment is used to illustrate the lithium ion battery disclosed in the present invention and the preparation method thereof, including the following operation steps:

[0117] 1) Preparation of electrolyte

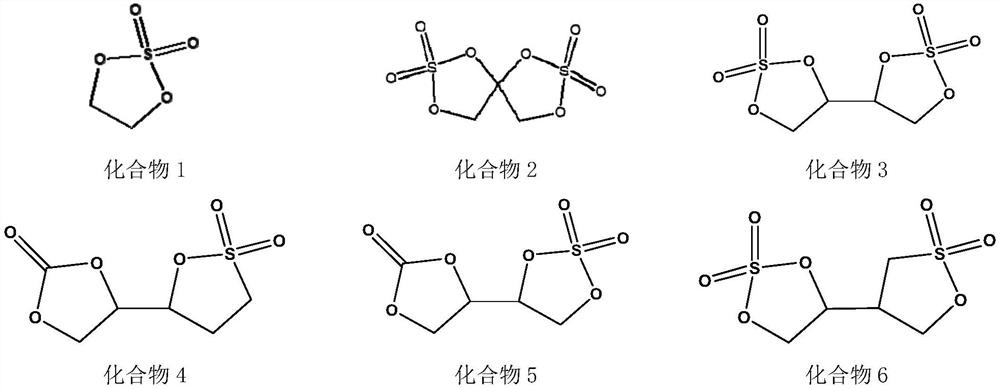

[0118] Ethylene carbonate (EC), dimethyl carbonate (DMC), and ethyl methyl carbonate (EMC) were mixed, and then lithium hexafluorophosphate (LiPF) was added. 6 ) to a mass concentration of 14.4%, add additives. The selection, content, cyclic carbonate content, electrical conductivity and total alcohol mass percentage content of additives in the non-aqueous electrolyte are shown in Table 2.

[0119] 2) Preparation of positive plate

[0120] The cathode active material LiNi is mixed in a mass ratio of 97:1.5:1.5 0.8 Co 0.1 Mn 0.1 O 2 , conductive carbon black Super-P and binder polyvinylidene fluoride (PVDF), and then disperse them in N-methyl-2-pyrrolidone (NMP) to obtain positive electrode slurry. The slurry is evenly coated on both sides of the alumin...

Embodiment 2~33

[0129] Examples 2 to 33 are used to illustrate the lithium ion battery disclosed in the present invention and the preparation method thereof, including most of the operation steps in Example 1, and the differences are:

[0130] The selection, content, cyclic carbonate content, electrical conductivity and total alcohol mass percentage of the additives shown in Table 1 were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com