Assembly parameter adaptive optimization method and system for intensive bus duct

A busway, self-adaptive technology, applied in the field of self-adaptive optimization method and system of assembly parameters of dense busway, can solve the problems of poor assembly effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

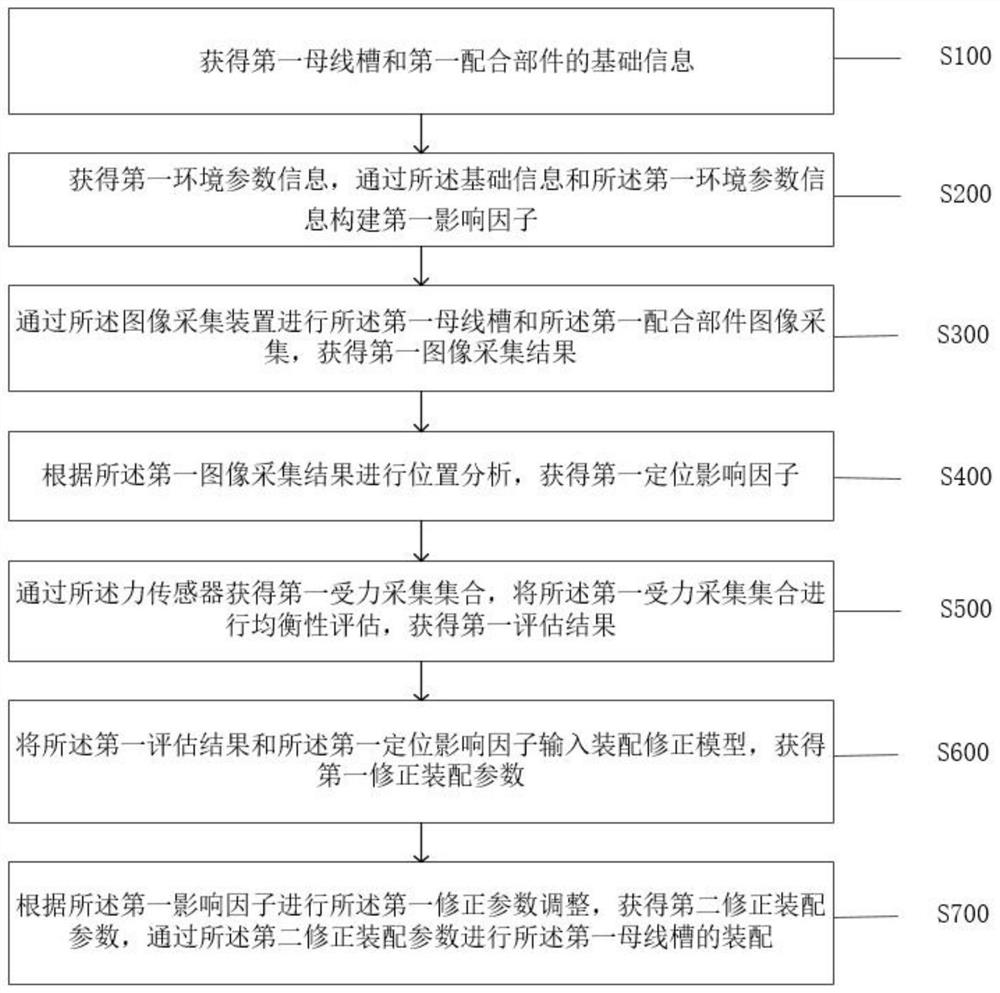

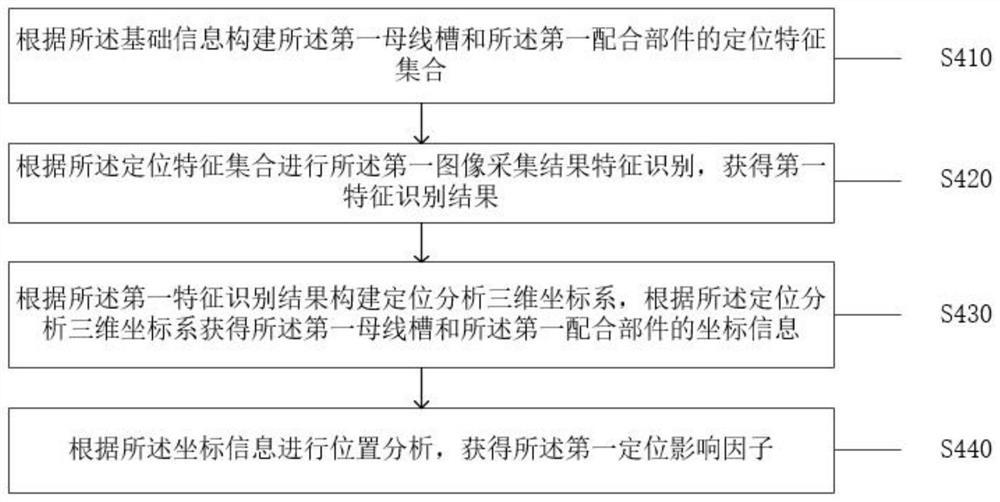

[0027] like figure 1 As shown, the present application provides a method for self-adaptive optimization of assembly parameters of dense bus ducts, the method is applied to an intelligent optimization system for assembly parameters, and the intelligent optimization system for assembly parameters is connected in communication with an image acquisition device and a force sensor, so The methods described include:

[0028] Step S100: obtaining basic information of the first busway and the first mating component;

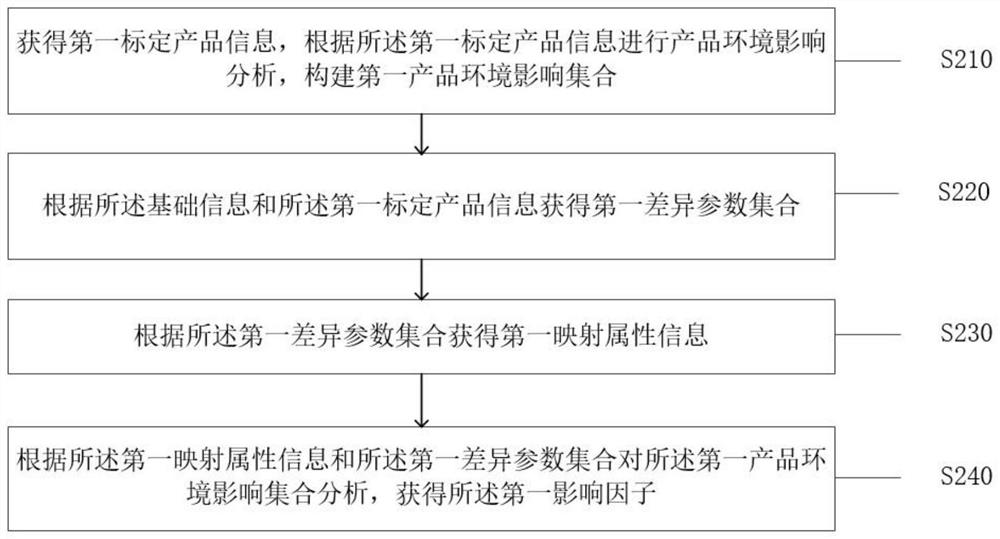

[0029] Step S200: obtaining first environmental parameter information, and constructing a first impact factor by using the basic information and the first environmental parameter information;

[0030] Specifically, the assembly parameter intelligent optimization system is a system for intelligent calculation and optimization of assembly parameters, the image acquisition device is a device that can perform image acquisition, generally a high-definition CCD camera, and the...

Embodiment 2

[0087] Based on the same inventive concept as the method for self-adaptive optimization of assembly parameters of a dense bus duct in the foregoing embodiment, the present invention also provides an adaptive optimization system for assembly parameters of a dense bus duct, such as Figure 5 As shown, the system includes:

[0088] a first obtaining unit 11, the first obtaining unit 11 is used to obtain the basic information of the first bus bar and the first mating component;

[0089] a second obtaining unit 12, the second obtaining unit 12 is configured to obtain first environmental parameter information, and construct a first impact factor by using the basic information and the first environmental parameter information;

[0090] a third obtaining unit 13, the third obtaining unit 13 is configured to perform image capturing of the first busway and the first mating component through an image capturing device to obtain a first image capturing result;

[0091] a first analysis un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com