A hydraulic support installation mechanism and its application

A technology of installation mechanism and hydraulic support, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve problems such as errors in the installation of hydraulic support, restrictions on the assembly process of hydraulic support, and high labor intensity of hydraulic support. The effect of economic benefits and market value, ingenious design and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

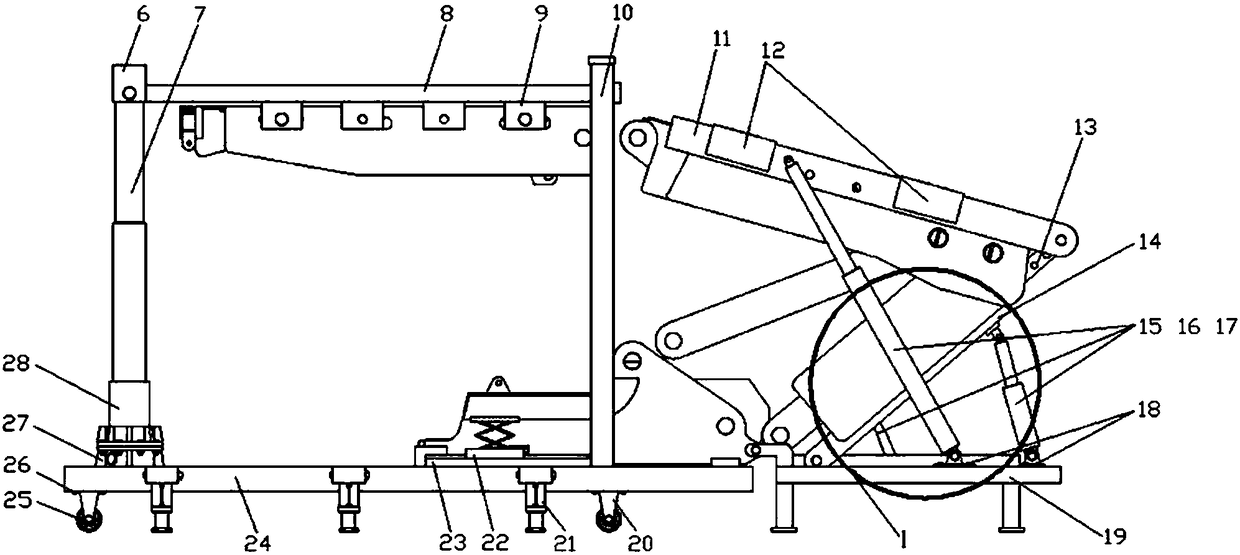

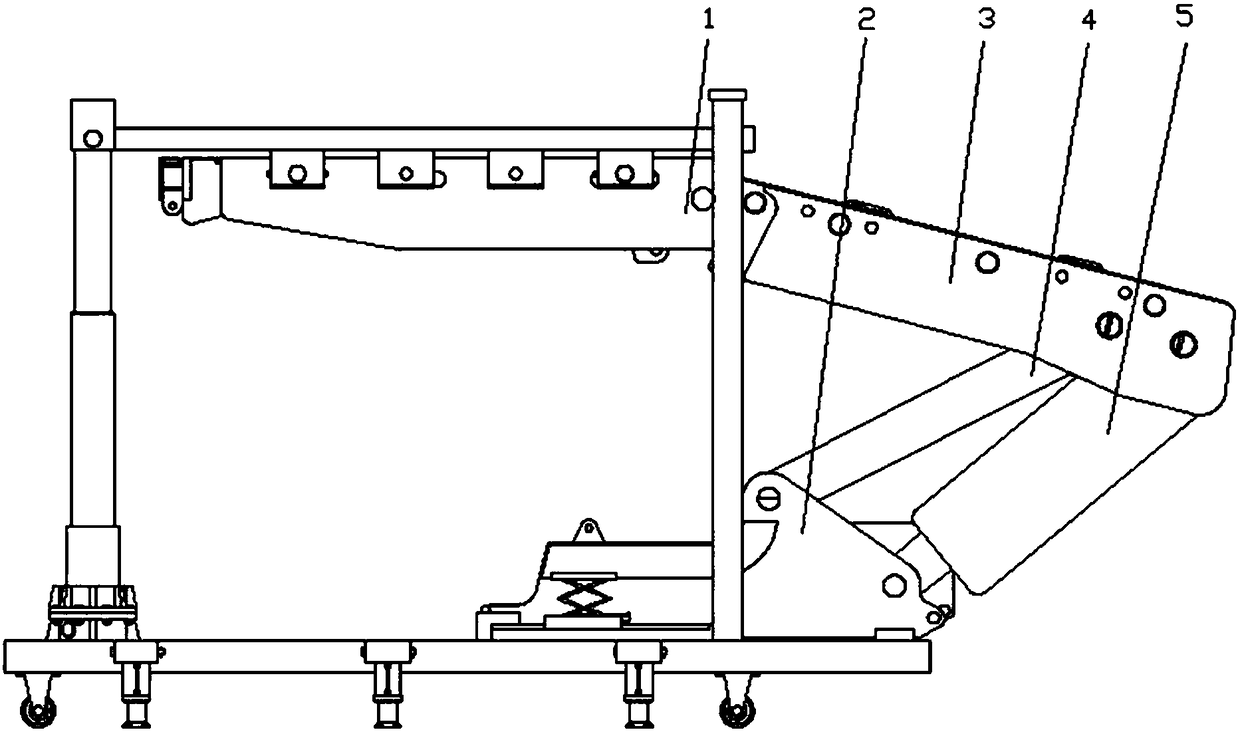

[0043] Such as Figure 1 to Figure 8 As shown, this embodiment provides a hydraulic support installation mechanism, including a top beam displacement mechanism and a cover beam assembly pushing mechanism, wherein:

[0044] The top beam displacement mechanism includes a scooter, a lifting device and a horizontal pushing device, the lifting device is arranged on the scooter, and the horizontal pushing device is arranged on the top of the lifting device;

[0045] The shielding beam assembly pushing mechanism includes base plate 19, load beam frame 11, the first pushing beam frame 13, the second pushing beam frame 14, the third pushing beam frame 68 and three telescopic support rods, the first pushing beam frame 13 One end is hinged with the load beam frame 11, the other end is connected with the second push beam frame 14, and the bottom ends of the second push beam frame 14 and the third push beam frame 68 are respectively hinged with the bottom plate 19; the load beam frame 11, ...

Embodiment 2

[0057] A hydraulic support installation mechanism, the structure is as described in Embodiment 1, the difference is that: the upper and lower sides of the car plate 24 are provided with lifting platform devices, and the lifting platform devices include slide rails 23, sliders 22, and a second horizontal push jack 45. Telescopic hinge 44 and support platform 46; one end of the slide rail 23 is connected with the bearing column 10 through the second pin 47, the slide block 22 is arranged on the slide rail 23, the top of the telescopic hinge 44 is connected with the bottom of the support platform 46, the bottom The end is connected with the slide block 22, and the horizontal second moving jack 45 is connected with the telescopic hinge 44. When the horizontal second moving jack 45 works, the telescopic hinge 44 is driven to extend or shrink in the vertical direction so as to drive the lifting of the supporting platform. The lifting table device provides some auxiliary functions for...

Embodiment 3

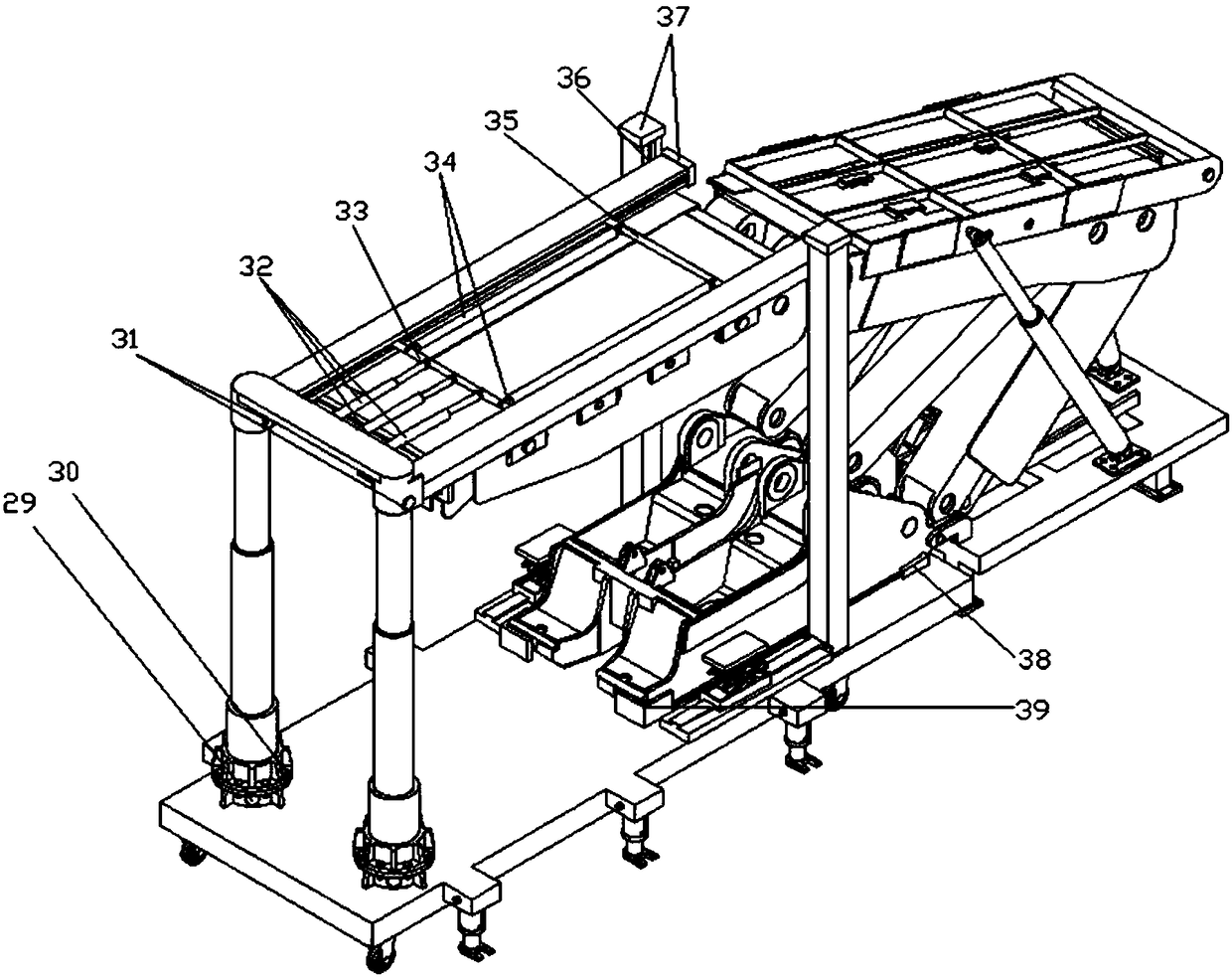

[0060] A hydraulic support installation mechanism, the structure is as described in Embodiment 2, the difference is that four positioning blocks are also arranged on the vehicle plate 24, and the four positioning blocks are symmetrically arranged on both sides of the lifting platform device and connected with the lifting platform The device is parallel, wherein two positioning blocks 38 are positioned at the right side of the lifting platform device, and two positioning blocks 39 are positioned at the left side of the lifting platform device (such as figure 2shown), the four positioning blocks can slide on the vehicle plate 24 (the vehicle plate is provided with corresponding grooves) to adjust the distance between the positioning blocks. Its advantages are that, firstly, the positioning block acts as a positioning guide for the base, so that after the base is moved in place, the mounting holes at the bottom ends of the front and rear connecting rods in the cover beam assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com