Elevation installation method for H-shaped steel type column or support

An installation method and H-beam technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of inaccurate installation, and achieve the effect of speeding up the installation progress, high efficiency and slow progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] An elevation installation method for an H-shaped steel column or bracket of the present embodiment includes the following steps:

[0043] S1. Measure the depth of the cup mouth to ensure that the depth of the cup mouth meets the requirements of the grouting layer;

[0044] S2. Measure the elevation of the upper plane of the base of the cup mouth, and process the upper plane of the cup mouth to ensure that the upper plane of the cup mouth is flat;

[0045] S3. According to the weight of the H-shaped steel column or bracket and the width of the cup mouth, select the appropriate elevation plate;

[0046] S4. According to the depth of the H-shaped steel column or bracket inserted into the cup mouth, mark the insertion line on the H-shaped steel column or bracket that is flush with the elevation of the upper plane of the cup mouth foundation;

[0047] S5. Weld the elevation plate on the H-shaped steel column or bracket;

[0048] S6. Install H-shaped steel columns or bracke...

Embodiment 2

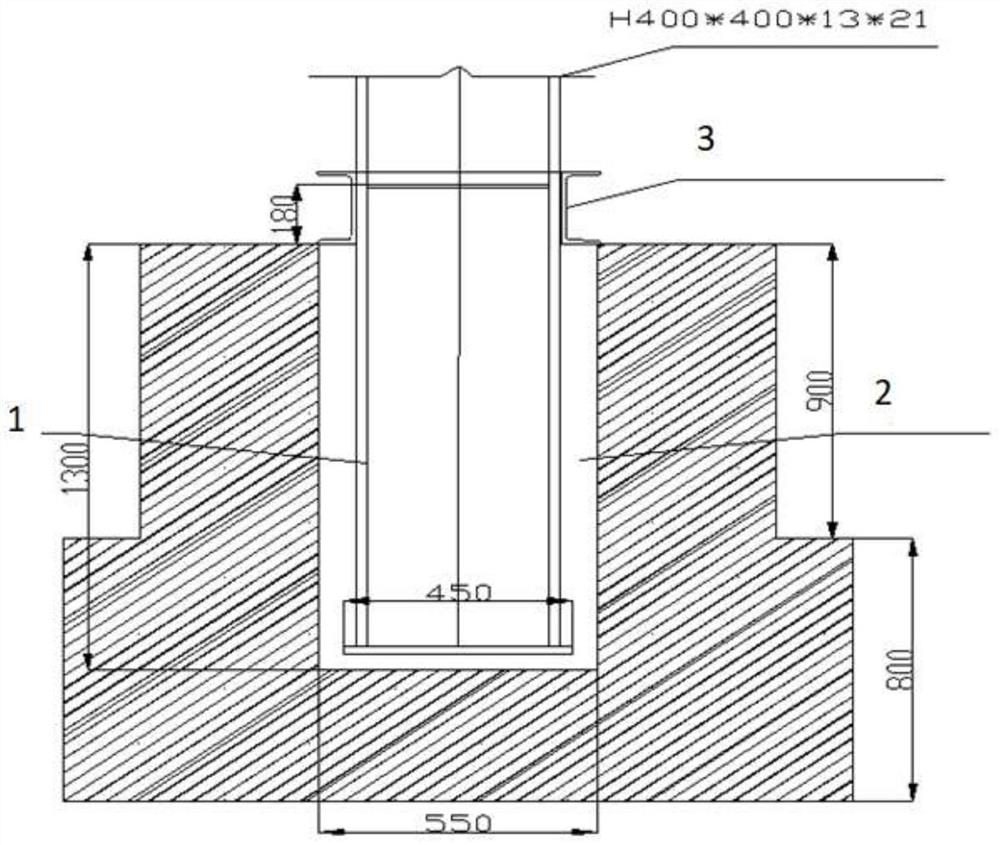

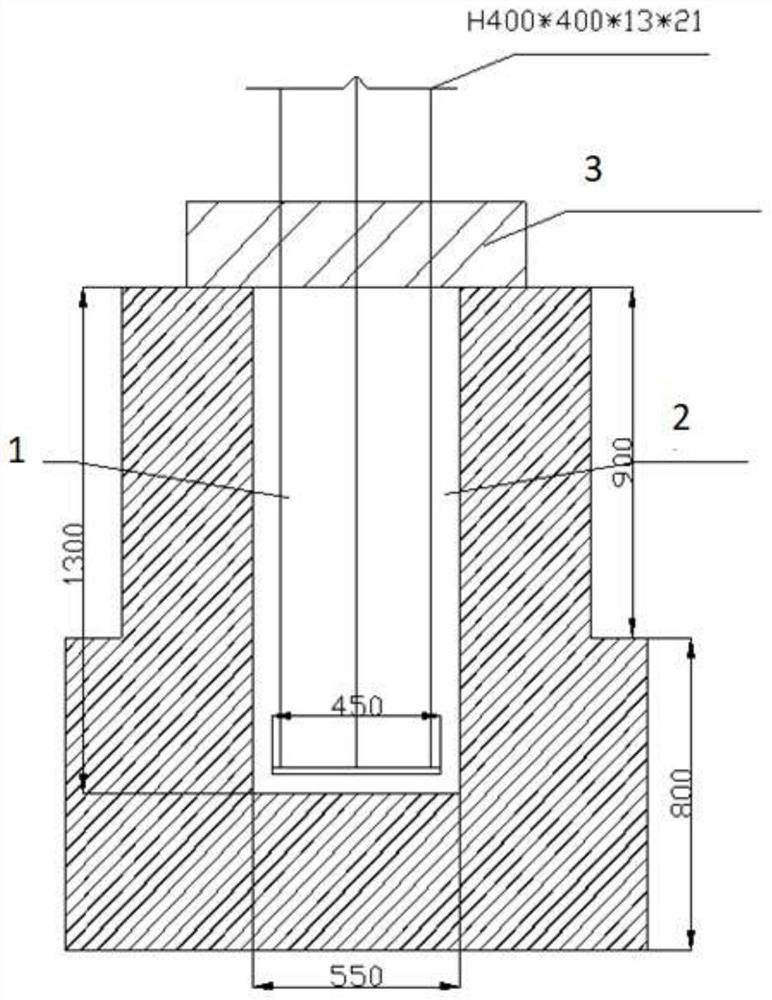

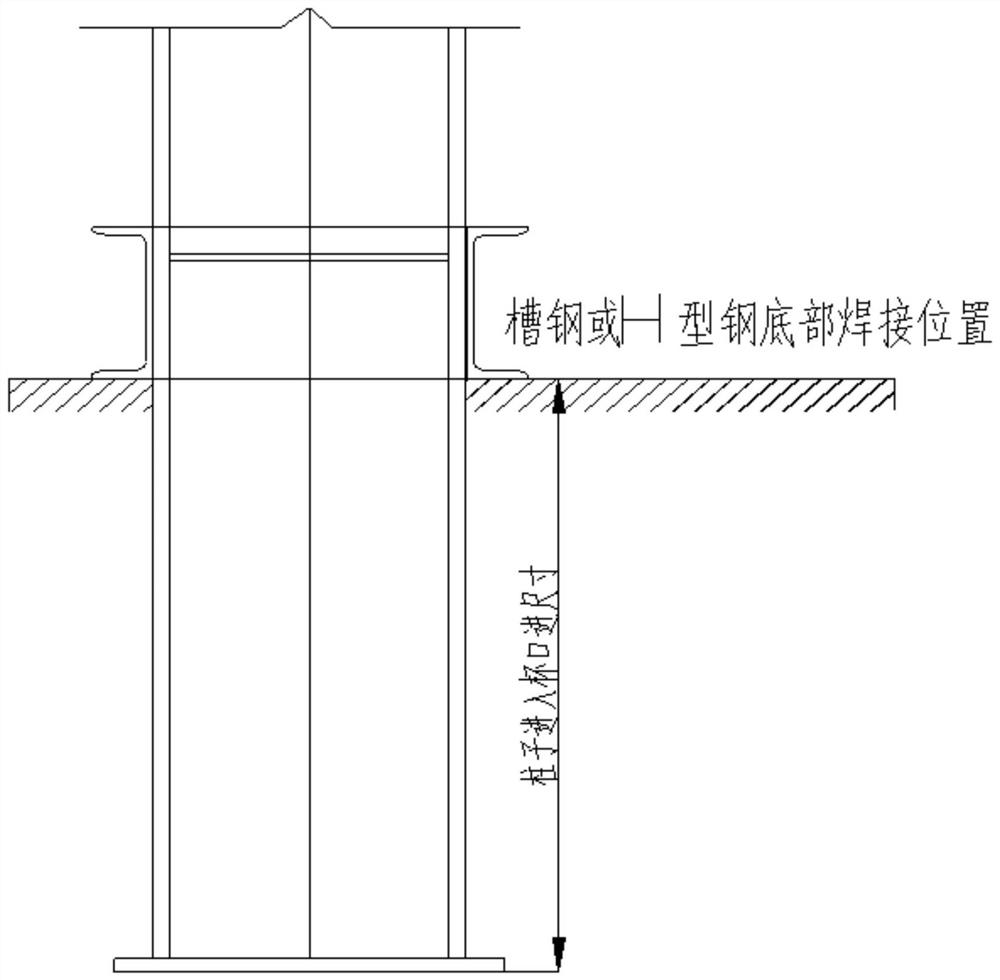

[0057] like Figure 1-4 As shown, an installation effect diagram of an elevation installation method of an H-shaped steel column or bracket is shown, including an H-shaped steel column or bracket 1 , a cup mouth 2 , an elevation plate 3 , and a triangular wedge 4 . like figure 1 and 2 As shown, part of the H-shaped steel column or bracket 1 is placed in the cup mouth 2, the H-shaped steel column or bracket 1 is welded with the benchmark plate 3, and the elevation plate 3 is supported on the cup mouth 2, so that the H-shaped steel column or bracket 1 extends The length of the cup inlet 2 is a design requirement. like image 3 As shown, the welding position of the H-shaped steel column or bracket 1 and the bottom of the elevation plate 3 is the plane elevation of the cup mouth 2, so as to ensure that the length of the H-shaped steel column or bracket 1 extending into the cup mouth 2 is more accurate. like Figure 4 As shown, the H-shaped steel column or bracket 1 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com