Fermentation equipment for preventing loss of nutrient substances in feed

A technology of nutrients and fermentation equipment, applied in the field of fermentation equipment, can solve the problems of feed heat cannot be discharged from the fermentation tank in time, loss of nutrients, high local temperature, etc., and achieve the effect of preventing local temperature from being too high, strong applicability, and easy heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

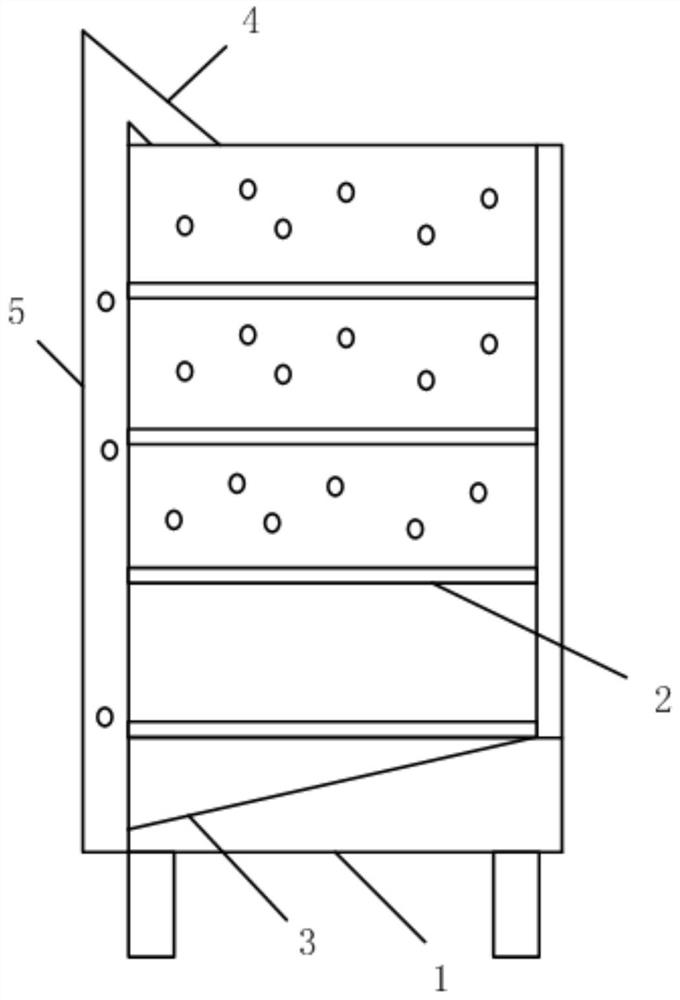

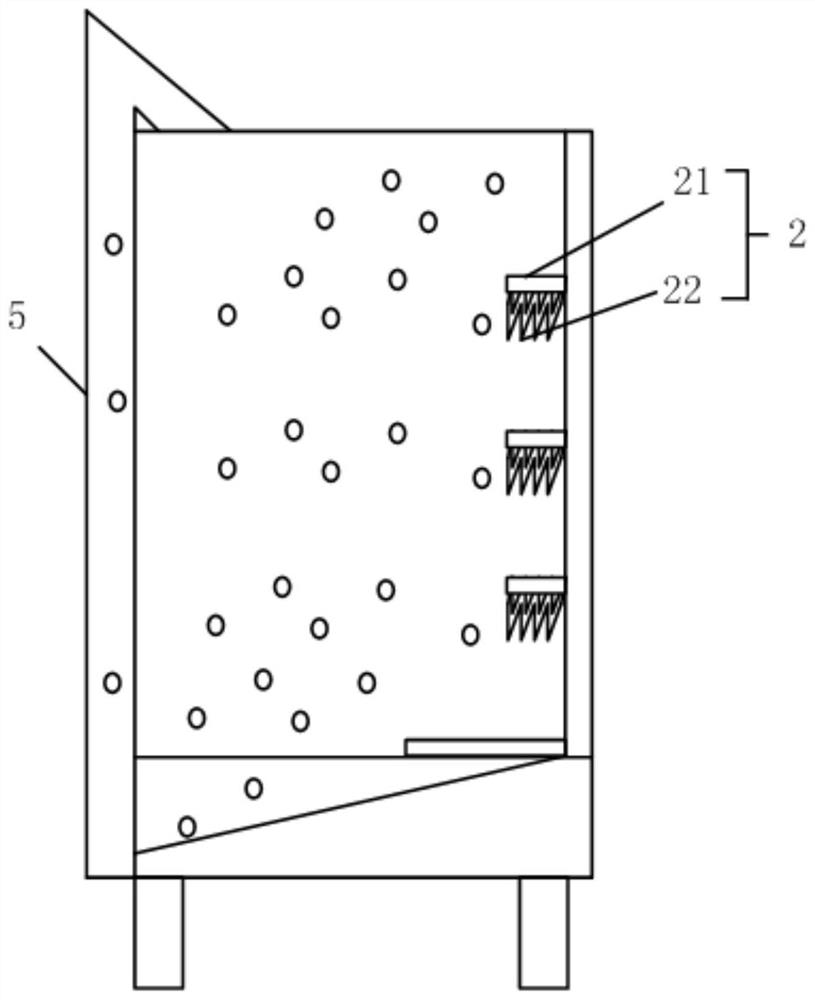

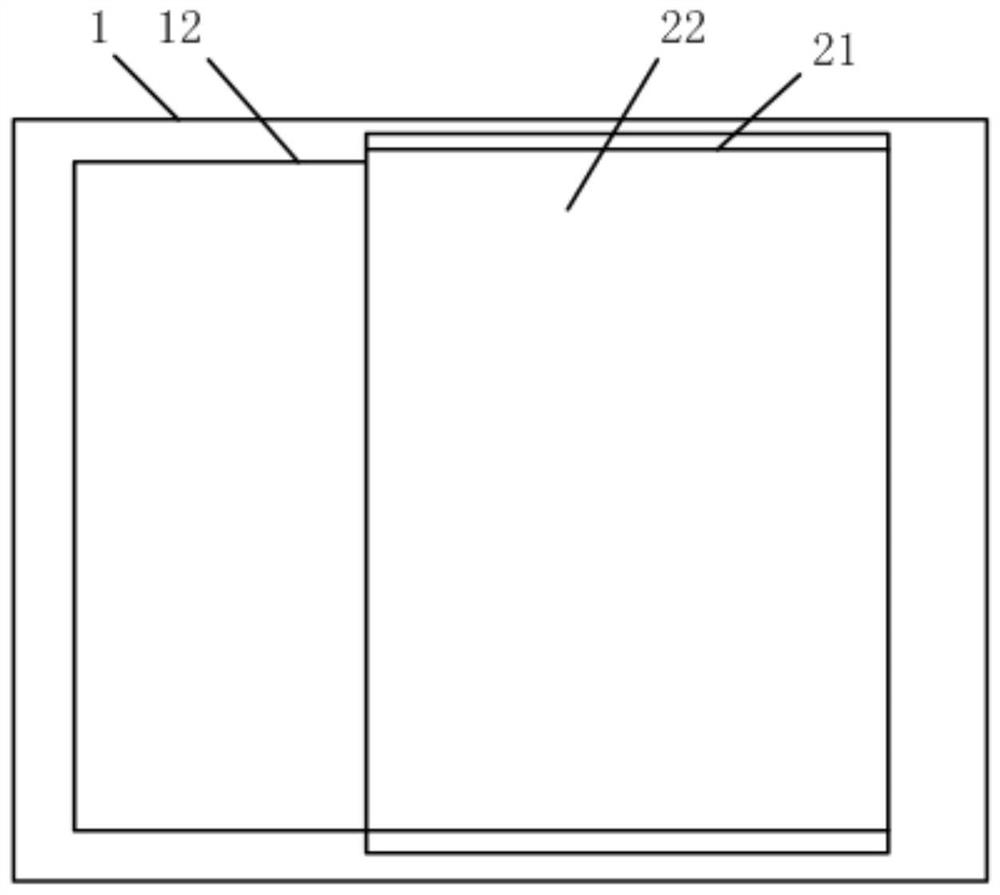

[0037] A fermentation device for preventing the loss of nutrients inside the feed, see Figure 1-3 , including a tank body 1, the inner wall of the tank body 1 is in the shape of a cube, which adopts the structure of the tank body 1 in the prior art, such as the structure of the tank body 1 with a temperature control device.

[0038]The tank body 1 is provided with a material interception device 2, a bottom circulation port 3 and a top circulation port 4. The bottom circulation port 3 is located below the material interception device 2 and is located at the bottom of the tank body 1. The top of the bottom circulation port 3 is connected to the material interception device. There is a distance between the bottoms of 2. The top circulation port 4 is located at the top of the tank body 1, and is located above the material interception device 2. There is a material lifting device 5 outside the tank body 1, and the bottom of the material lifting device 5 communicates with the bottom...

Embodiment 2

[0047] A fermentation equipment for preventing the loss of nutrients inside the feed, the structure is basically the same as that of Example 1, the difference is that, see Figure 4-7 , the interception device 2 includes two top telescopic rods 23, two bottom telescopic rods 24, a top baffle 25, and a bottom baffle 26. The top telescopic rod 23 and the bottom telescopic rod 24 both adopt the electric telescopic rod structure of the prior art; The installation methods of the top telescopic rods 23 and the two bottom telescopic rods 24 refer to the position of the electric telescopic rods 21 in Embodiment 1. The difference is that the two bottom telescopic rods 24 are arranged under the top telescopic rods 23 in a one-to-one correspondence. And it is opposite to the extension direction of the top telescopic rod 23, for example, see Figure 5 , the fixed end of the top telescopic rod 23 is installed on the right side wall of the tank body 1, the telescopic end extends towards the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com