Carbon dioxide adsorption material and preparation method thereof

An adsorption material, carbon dioxide technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of inability to meet the needs of carbon dioxide capture, poor thermal stability of nitrogen-containing functional groups, uneven distribution, etc. The effect of carbon dioxide adsorption capacity, improvement of surface properties, and increase of carbon dioxide adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A carbon dioxide adsorption material and a preparation method thereof, comprising the following steps:

[0031] Step 1. Take 0.5g of carbon material and ultrasonically treat it in 5ml of ultrapure water for 5-10min; then add 0.1mol / L nitric acid dropwise to the obtained dispersion until the pH value of the dispersion=3; then at a constant temperature of 60°C Digestion for 2 hours. The carbon materials are carbon nanotubes, graphene or activated carbon.

[0032] In step 2, the carbon material activated by nitric acid in step 1 was washed 3 times at normal temperature with ultrapure water, and then dried at a constant temperature of 60°C in a constant temperature drying oven.

[0033] Step 3. After fully mixing the dried carbon material and glass beads obtained in step 2, it is flatly placed into the reaction chamber of the plasma modification equipment.

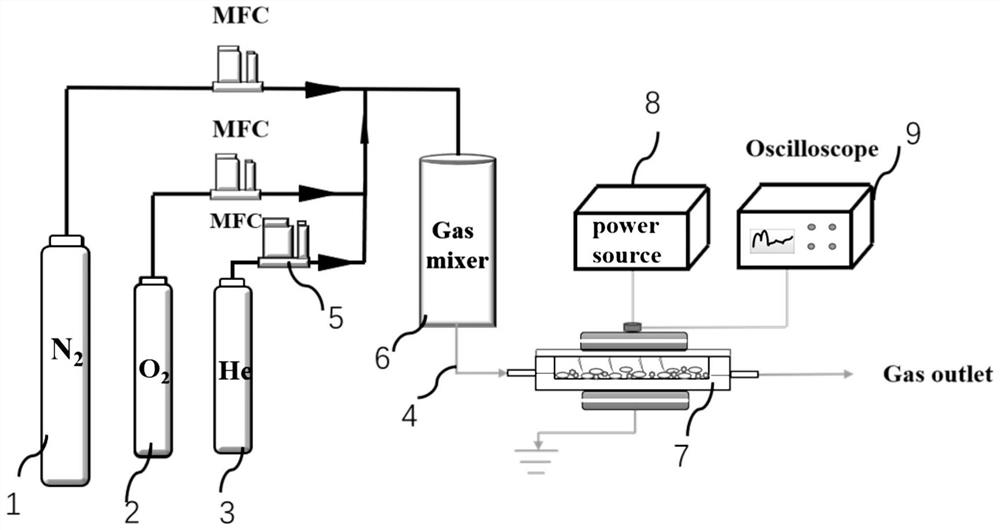

[0034] like figure 1 As shown, the plasma modification equipment includes a nitrogen source 1, an oxygen source 2,...

Embodiment 2

[0037] A carbon dioxide adsorption material and a preparation method thereof, comprising the following steps:

[0038] Step 1. Take 1 g of carbon material, ultrasonically treat it in 10 ml of ultrapure water for 5 min, then add 0.1 mol / L nitric acid to the obtained dispersion dropwise until the pH value of the dispersion is 3, and then digest it for 2 hours at a constant temperature of 60 °C . As the carbon material, carbon nanotubes, graphene or activated carbon are used.

[0039] In step 2, the carbon material activated by nitric acid in step 1 was washed 3 times at normal temperature with ultrapure water, and then dried at a constant temperature of 60°C in a constant temperature drying oven.

[0040] Step 3. After fully mixing the dried carbon material and glass beads obtained in step 2, it is flatly placed into the reaction chamber of the plasma modification equipment. The plasma modification equipment is the same as in Example 1.

[0041] Step 4: Keep the helium volume a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com