Magnesium oxide powder feeding hopper and copper pipe copper sheath magnesium oxide insulated cable filling method

A technology of magnesium oxide powder and insulating cable, which is used in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problem of uneven density distribution of magnesium oxide powder, shorten the service life of fireproof cables, and reduce the conductivity of fireproof cables. and other problems, to achieve the effect of improving the resistance to bending and extrusion impact, high hardness, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

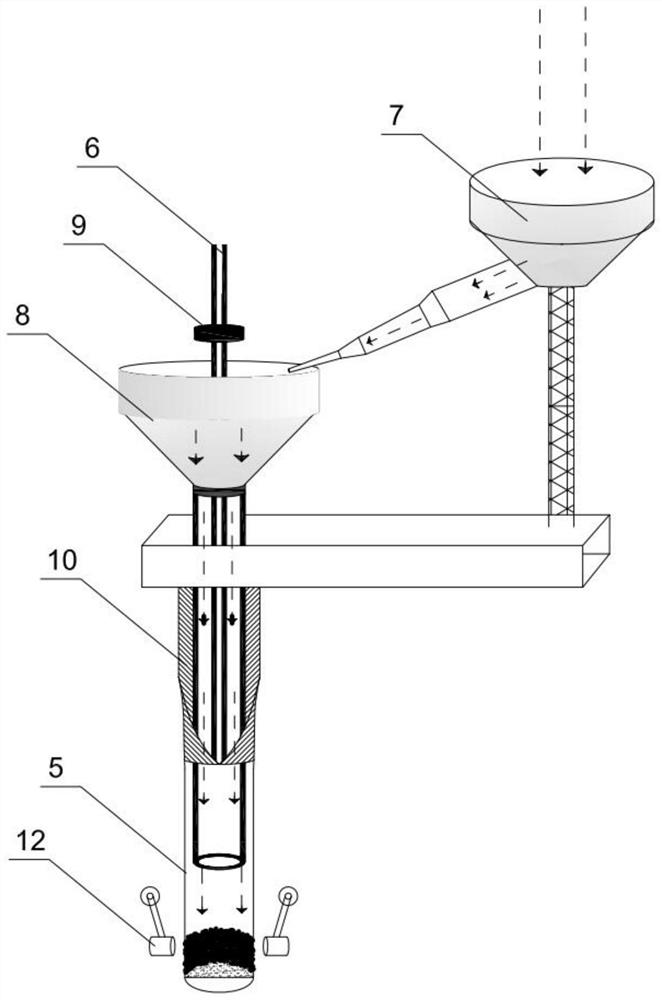

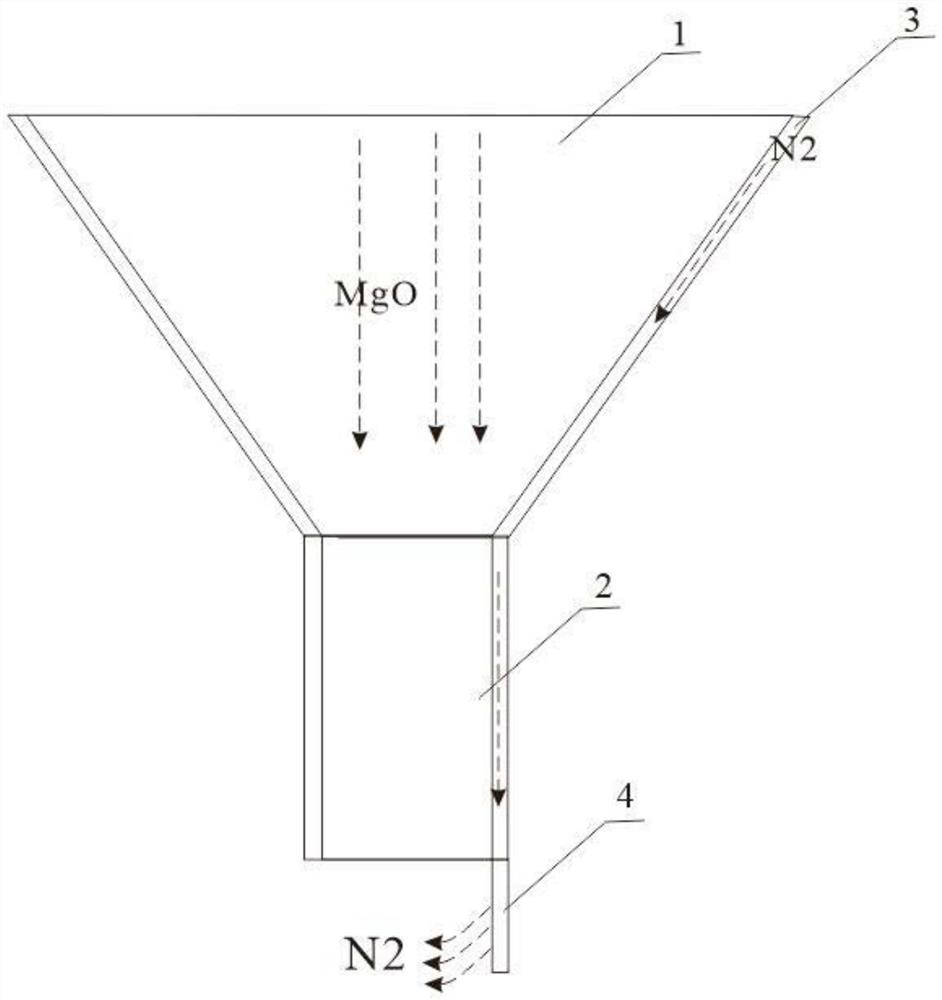

[0030] like figure 1 As shown, the existing filling system has an upper hopper 7, a lower hopper 8, a fixed core tube sleeve 9, a copper core 6, a copper tube copper sheath 5 and a drainage tube, and the upper end of the drainage tube is connected to the discharge port of the lower hopper 8. , the lower end of the drainage tube extends into the copper tube copper sheath 5 rolled with the copper tape 10, the fixed core tube sleeve 9 is located above the lower hopper 8, and the copper core 6 passes through the fixed core tube sleeve 9 and sequentially from the lower hopper 8 , The drainage tube extends into the copper tube copper sheath 5 after passing through, and the magnesium oxide powder is placed in the upper hopper, passes through the upper hopper for first-level buffering, and the lower hopper for second-level buffering, and then enters the drainage tube. The moving speed of the copper tape and the copper core is consistent with the flow rate of the magnesium oxide powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com