Reinforcement method of reinforced concrete box type roadbed

A reinforced concrete, box-shaped technology, applied in the direction of instruments, geometric CAD, design optimization/simulation, etc., can solve the problems of inability to adapt to the differentiated geological conditions in different regions, the overall strength is difficult to achieve the specified strength index, and the geological conditions vary greatly. , to achieve the effect of high construction efficiency, good structural strength and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

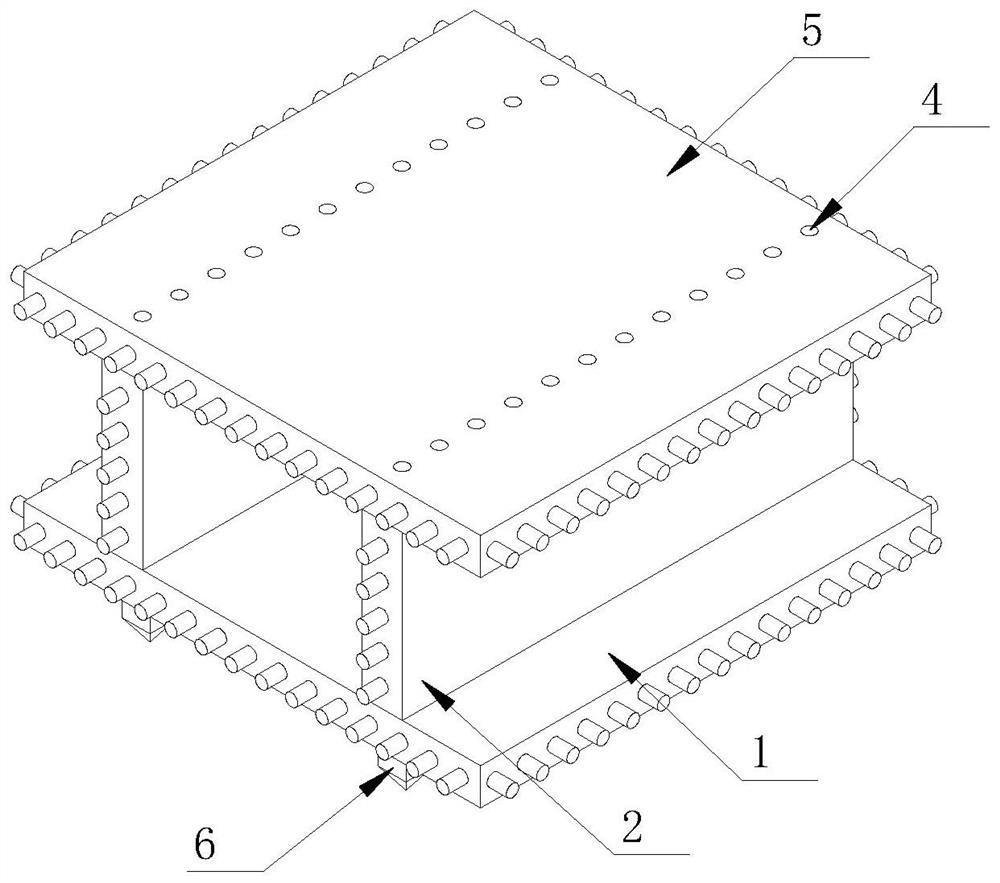

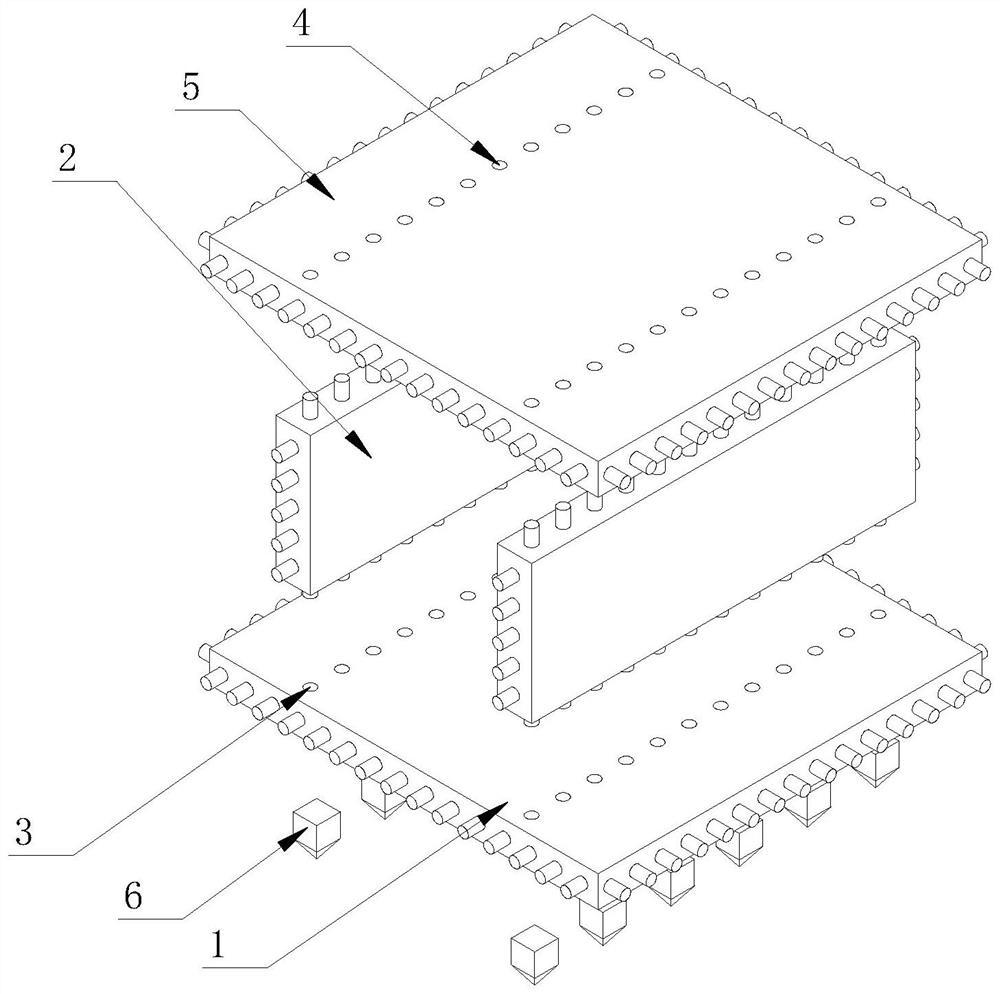

[0127] A reinforcement method for a reinforced concrete box-type subgrade, comprising the following steps:

[0128] Due to the high stiffness of the box-type subgrade along the laying direction of the line, structural damage will generally not occur, so reinforcement is only performed by calculating the cross-section force of the box-type subgrade.

[0129] Selection of materials: In order to standardize the construction and improve the construction efficiency, the steel bars are made of tertiary steel, and the concrete is C40 concrete.

[0130] Roof reinforcement:

[0131] The width of the roof is 8600mm and the height is 500mm. The roof is simplified as a beam with two rigid supports. According to the design specification of high-speed railway, the stressed part of the roof is approximated to bear a uniform load, and according to the plate belt per meter width Calculation.

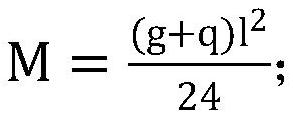

[0132] Mid-span bending moment:

[0133]

[0134]

[0135] Where: M is the mid-span bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com