Butt flange metal sealing cover structure

A technology of metal sealing and butt joint flange, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing components, etc., which can solve the problem of inability to guarantee sealing performance and connection firmness, easy wear of sealing ring, inconvenient operation, sealing performance, etc. problem, to achieve the effect of improving the connection firmness, sealing effect and connection tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

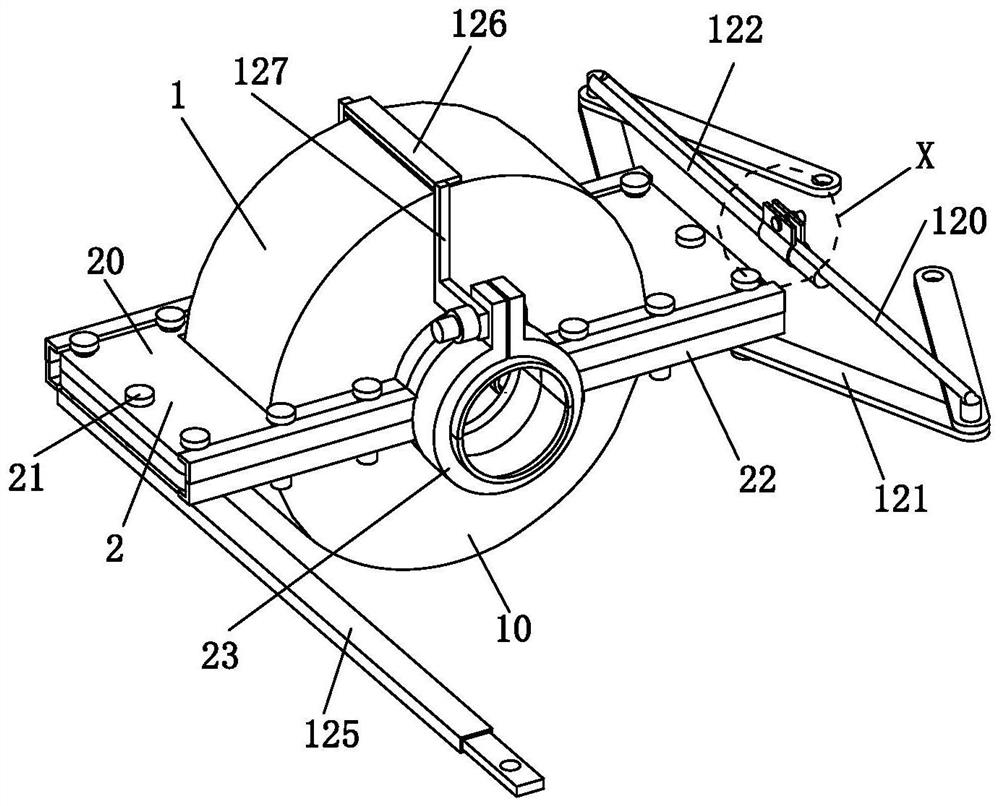

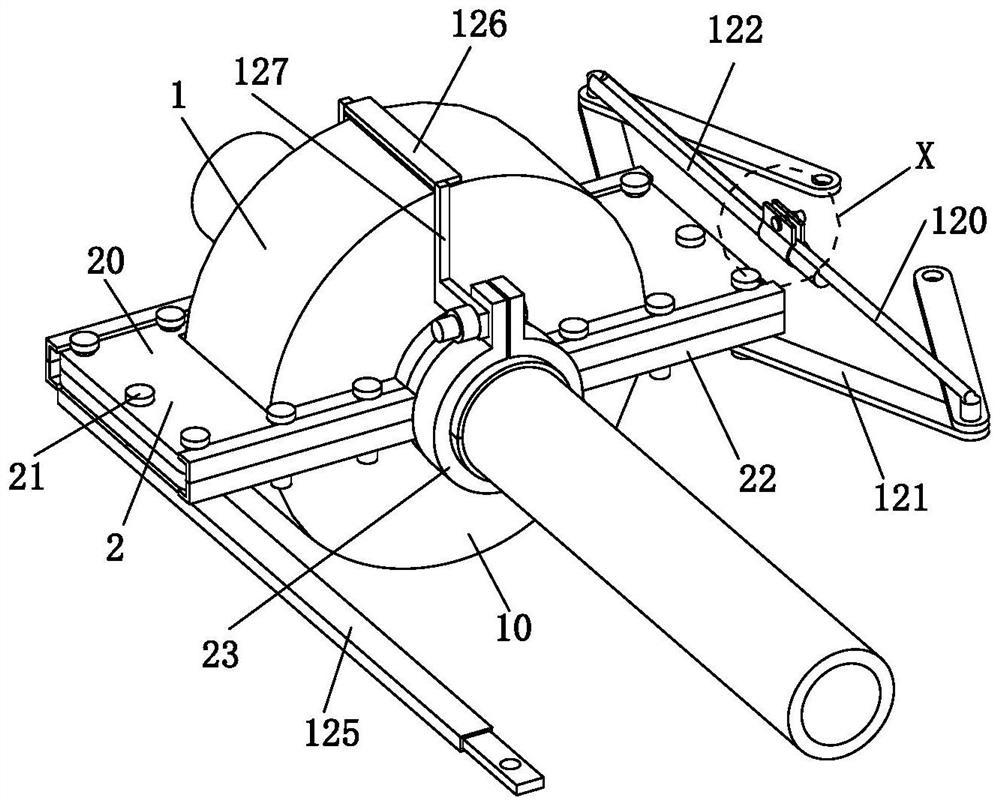

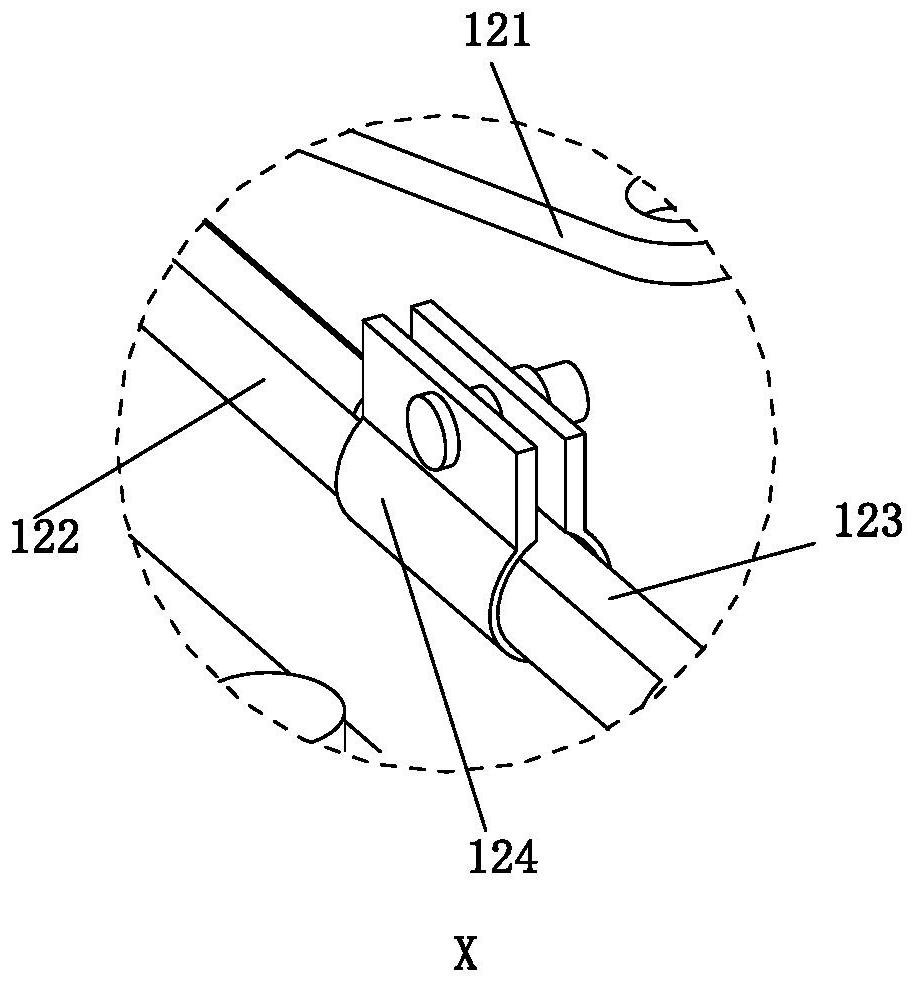

[0043] This embodiment provides a butt flange metal sealing cover structure for sealing the flange installed on the pipeline. The butt flange metal sealing cover structure includes a main cover mechanism 1 and an outer sealing mechanism 2, and the outer sealing mechanism 2 is fixed On the outside of the main cover mechanism 1, it is used to seal the main cover mechanism 1; the main cover mechanism 1 includes a semicircular cover 10 and a bottom support plate 11, a turning plate 12, an ear block 13, and a U-shaped clamping plate located inside the semicircular cover 10. 14. Fixing bolts 15, telescopic rods 16 and rubber suction blocks 17;

[0044] The number of the semicircular casings 10 is at least two, and the two semicircular casings 10 are arranged symmetrically up and down, and an accommodating cavity for accommodating flanges is formed inside; The bottom support plate 11 is supported by the semicircular cover 10, and one side of the bottom support plate 11 is matched wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com