Construction method of reinforced concrete cast-in-place pile under complex geological conditions

A technology of complex geological conditions and reinforced concrete, which is applied in earthwork drilling, drilling equipment and methods, excavation, etc., can solve problems such as high cost, uneven and uneconomical original geology and landforms of the project, and achieve cost reduction and work intensity. Conducive to environmental protection, improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

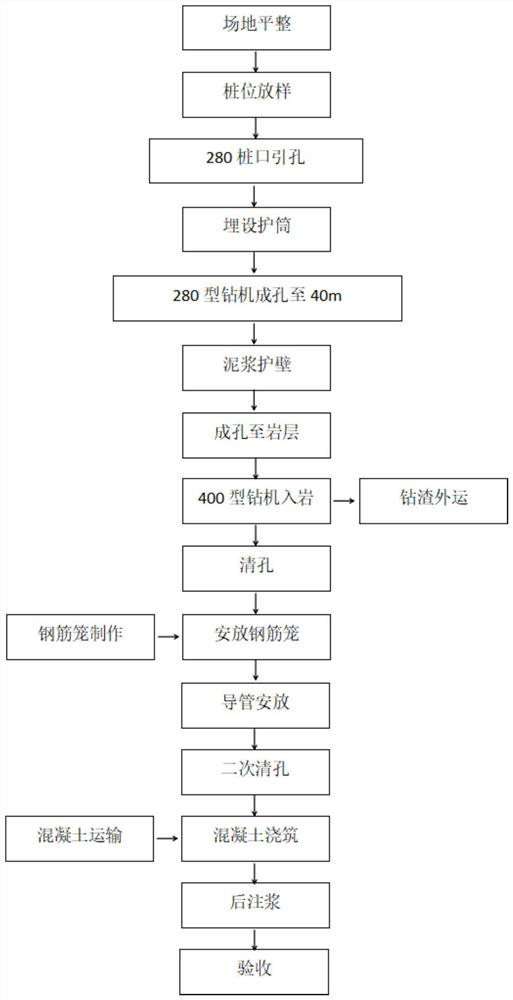

[0039] A construction method for reinforced concrete cast-in-place piles under complex geological conditions, comprising:

[0040] S1. The site is leveled, and the pile position is laid out;

[0041] Before construction, use an excavator for site leveling, positioning and laying out, and reserve 200 thick fly ash for manual leveling. The site must be leveled and compacted before the on-site lay-out to ensure that the mechanical driving and positioning of the pile foundation is stable and accurate. According to the coordinate control point given by the construction unit, the total station is used to carry out the stakeout and elevation measurement, and the RTK is re-measured and the error is controlled within 5mm.

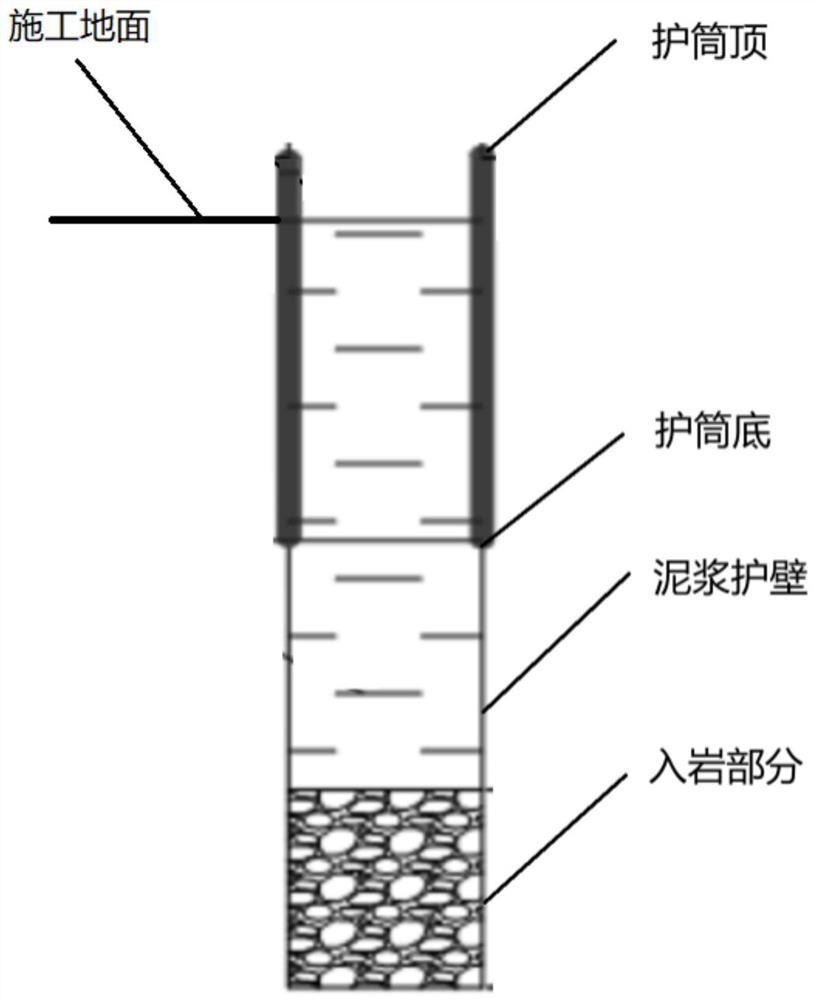

[0042] S2. Make a hole, borrow soil, and install the steel casing to a distance of X meters from the natural floor;

[0043] According to the measured stake points, after the crawler crane and the pipe rubbing machine are roughly in place, repeat the test again, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com