Desiliconization and hardness removal integrated device and method

A technology of desiliconization and desiliconization agent, which is applied in chemical instruments and methods, water softening, water/sewage multi-stage treatment, etc., can solve the problems of lack of efficient means, hardness or silicon single removal efficiency, etc., and achieve process integration high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

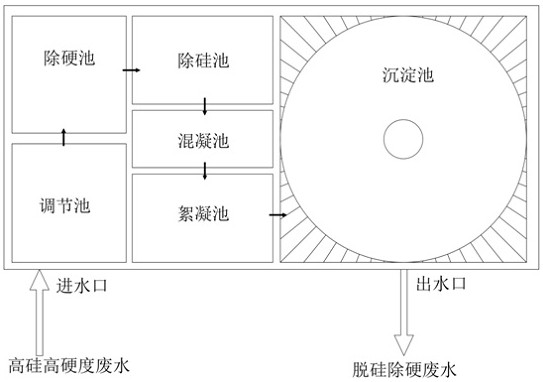

[0019] The process device and flow chart of this embodiment are shown in figure 1 .

[0020] This embodiment provides an integrated device for desiliconization and hardness removal. The device includes an adjustment tank, a hardness removal tank, a silicon removal tank, a coagulation tank, a flocculation tank and a sedimentation tank; wherein the volume of the adjustment tank is 25 m 3 , The volume of the hard pool is 25 m 3 , the volume of the desiliconization tank is 25 m 3 , the volume of the coagulation tank is 15 m 3 , the volume of the flocculation tank is 15 m 3 , the volume of the sedimentation tank is 280 m 3 . The above equipments are connected one by one, wherein the water outlet of the adjustment tank is the water inlet of the hard removal tank, the water outlet of the hard removal tank is the water inlet of the silicon removal tank, the water outlet of the silicon removal tank is the water inlet of the flocculation tank, and the water outlet of the flocculati...

Embodiment 2

[0023] This embodiment provides an integrated device for desiliconization and hardening removal. The device includes a conditioning tank, a hardening tank, a desiliconization tank, a coagulation tank, a flocculation tank and a sedimentation tank; wherein the volume of the adjustment tank is 30 m 3 , The volume of the hard pool is 30m 3 , the volume of the silicon removal tank is 33m 3 , the volume of the coagulation tank is 17m 3 , the volume of the flocculation tank is 33m 3 , the volume of the sedimentation tank is 280 m 3 . The above equipments are connected one by one, wherein the water outlet of the adjustment tank is the water inlet of the hard removal tank, the water outlet of the hard removal tank is the water inlet of the silicon removal tank, the water outlet of the silicon removal tank is the water inlet of the flocculation tank, and the water outlet of the flocculation tank is the water inlet of the flocculation tank. The water outlet is the water inlet of the ...

Embodiment 3

[0026] This embodiment provides an integrated device for desiliconization and hardening removal. The device includes a regulating tank, a hardening tank, a silicon removal tank, a coagulation tank, a flocculation tank and a sedimentation tank; wherein the volume of the regulating tank is 12 m 3 , The volume of the hard pool is 12 m 3 , the volume of the silicon removal tank is 12 m 3 , the volume of the coagulation tank is 1m 3 , the volume of the flocculation tank is 3m 3 , the volume of the sedimentation tank is 25 m 3 . The above equipments are connected one by one, wherein the water outlet of the adjustment tank is the water inlet of the hard removal tank, the water outlet of the hard removal tank is the water inlet of the silicon removal tank, the water outlet of the silicon removal tank is the water inlet of the flocculation tank, and the water outlet of the flocculation tank is the water inlet of the flocculation tank. The water outlet is the water inlet of the sedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com