Edge cutting equipment for processing soft package foil of battery

A battery soft pack and edge trimming technology, applied in metal processing, battery pack parts, circuits, etc., can solve the problems of occupying space, low degree of automation, large volume, etc., to reduce space occupation, flexible processing, and equipment. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

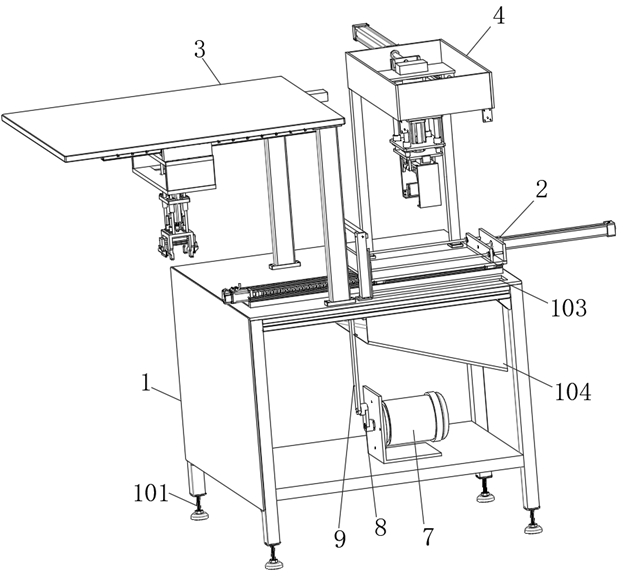

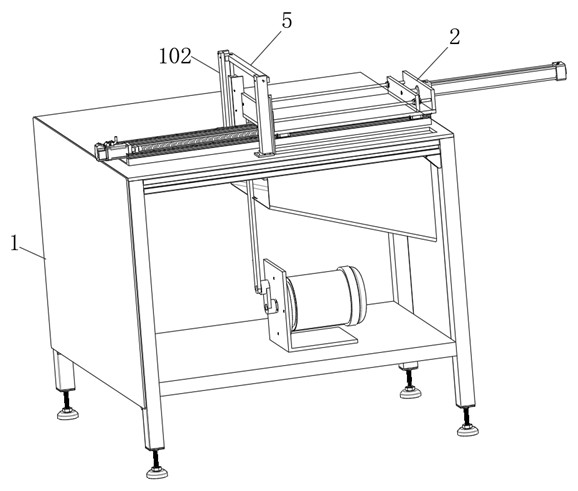

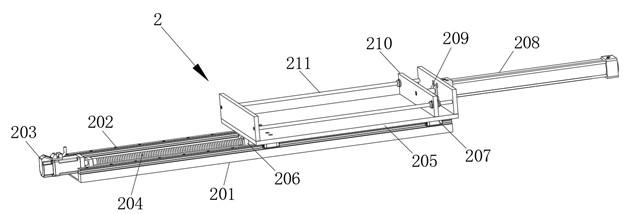

[0036] like Figure 1-Figure 9 As shown, an edge trimming device for battery soft package foil processing according to the present invention includes an operating table 1, a pushing component 2, a feeding component 3, an adjusting component 4, a cross bar 5 and a fourth motor 7. The top of the table 1 is provided with a push assembly 2, a feeding assembly 3 and an adjustment assembly 4. The feeding assembly 3 and the adjustment assembly 4 are respectively located at both ends of the push assembly 2, and the top of the operating table 1 is located between the feeding assembly 3 and the adjustment assembly 4. Two tool rests 102 are vertically fixed, and the two tool rests 102 are respectively located on both sides of the push assembly 2. A four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com