Radial positioning code disc

A radial positioning and code disc technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of radial overstress protection, the inability to achieve precise positioning at any radial position, etc., achieve rapid positioning and improve assemblability and the effect of maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

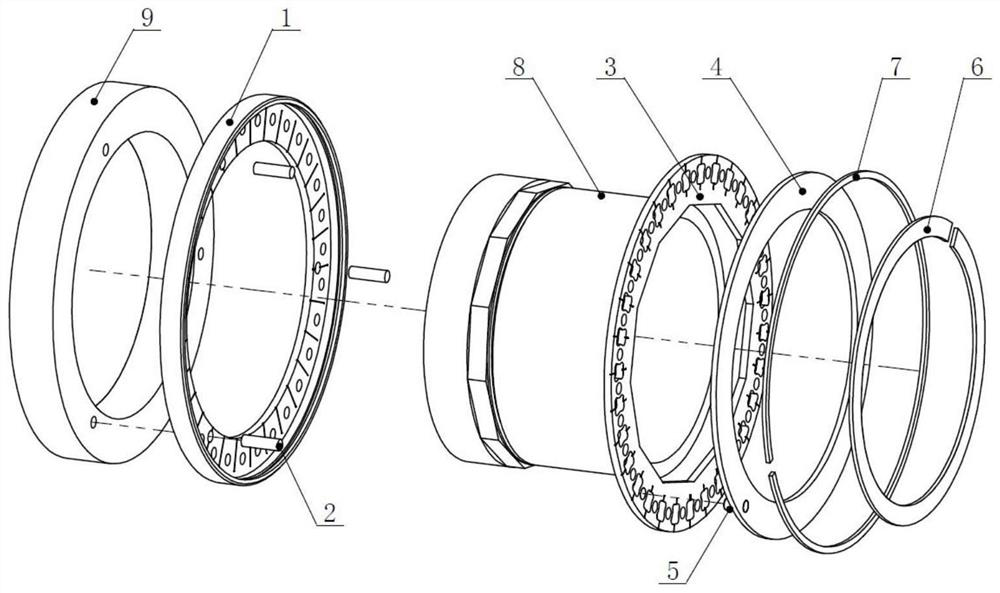

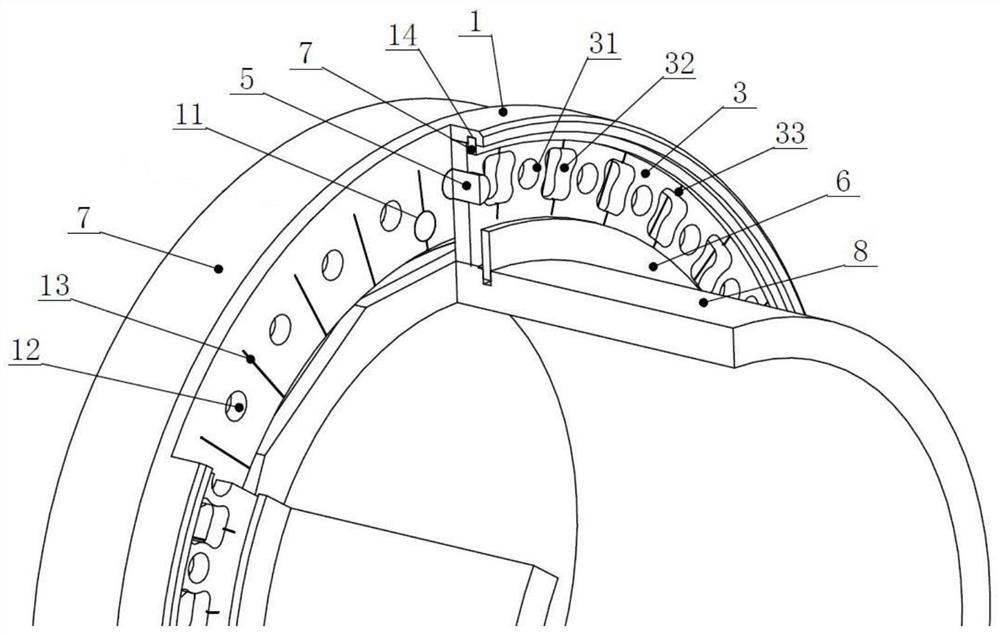

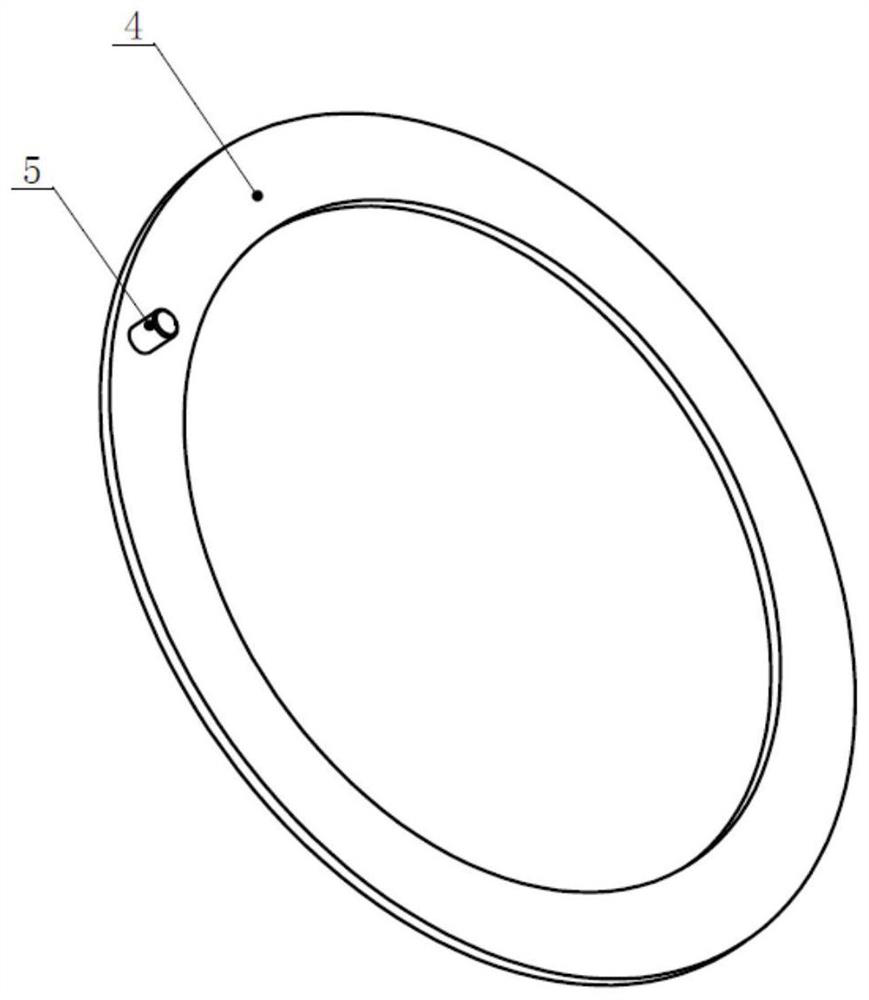

[0043] Example 1, see Figure 1-6 ,like figure 1 As shown, in this embodiment, a radial positioning code wheel includes:

[0044] Reference plate 1, floating plate 3, fixed ring 4, retaining ring 6, retaining ring 7, outer sleeve 9 and inner sleeve 8;

[0045] The reference disk 1 and the outer sleeve 9 are fixed to rotate as a whole, and the reference disk 1 is fixed on the end face of the outer sleeve 9;

[0046] The floating disk 3 and the inner sleeve 8 are fixed to rotate as a whole, and the floating disk 3 is fixed to the outer wall surface of the inner sleeve 8;

[0047] The inner sleeve 8 and the outer sleeve 9 are inserted and matched, and the inner sleeve 8 and the outer sleeve 9 can rotate with each other;

[0048] The reference disk 1 and the floating disk 3 are stacked and slidably matched; the reference disk 1 has n first holes 12, and the n holes are uniformly distributed in a ring shape, and the radius of the ring distribution circle is r; the floating disk ...

Embodiment 2

[0052] Example 2, see Figure 1-7 ,like figure 1 As shown, in this embodiment, a radial positioning code wheel includes:

[0053] Reference plate 1, floating plate 3, fixed ring 4, retaining ring 6, retaining ring 7, outer sleeve 9 and inner sleeve 8;

[0054] The reference disk 1 and the outer sleeve 9 are fixed to rotate as a whole, and the reference disk 1 is fixed on the end face of the outer sleeve 9;

[0055] The floating disk 3 and the inner sleeve 8 are fixed to rotate as a whole, and the floating disk 3 is fixed to the outer wall surface of the inner sleeve 8;

[0056] The inner sleeve 8 and the outer sleeve 9 are inserted and matched, and the inner sleeve 8 and the outer sleeve 9 can rotate with each other;

[0057] The reference disk 1 and the floating disk 3 are stacked and slidably matched; the reference disk 1 has n first holes 12, and the n holes are uniformly distributed in a ring shape, and the radius of the ring distribution circle is r; the floating disk ...

Embodiment 3

[0062] Example 3, see Figure 1-6 ,like figure 1 As shown, in this embodiment, a radial positioning code wheel includes:

[0063] Reference plate 1, floating plate 3, fixed ring 4, retaining ring 6, retaining ring 7, outer sleeve 9 and inner sleeve 8;

[0064] The reference disk 1 and the outer sleeve 9 are fixed to rotate as a whole, and the reference disk 1 is fixed on the end face of the outer sleeve 9;

[0065] The floating disk 3 and the inner sleeve 8 are fixed to rotate as a whole, and the floating disk 3 is fixed to the outer wall surface of the inner sleeve 8;

[0066] The inner sleeve 8 and the outer sleeve 9 are inserted and matched, and the inner sleeve 8 and the outer sleeve 9 can rotate with each other;

[0067] The reference disk 1 and the floating disk 3 are stacked and slidably matched; the reference disk 1 has n first holes 12, and the n holes are uniformly distributed in a ring shape, and the radius of the ring distribution circle is r; the floating disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com