Winding type film covering device based on column and tower structural body of house building

A film-covering device and structure technology, which is applied in the direction of building structure, building, building type, etc., can solve the problems that the waterproof film cannot be attached, is dangerous, and troublesome to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] as attached figure 1 to the attached Figure 9 shown:

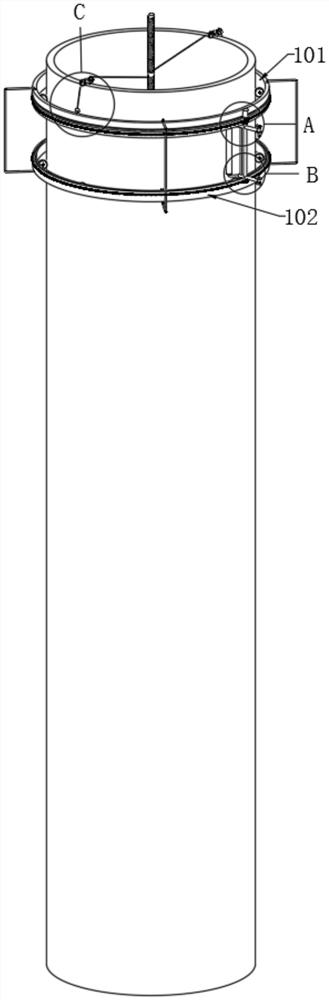

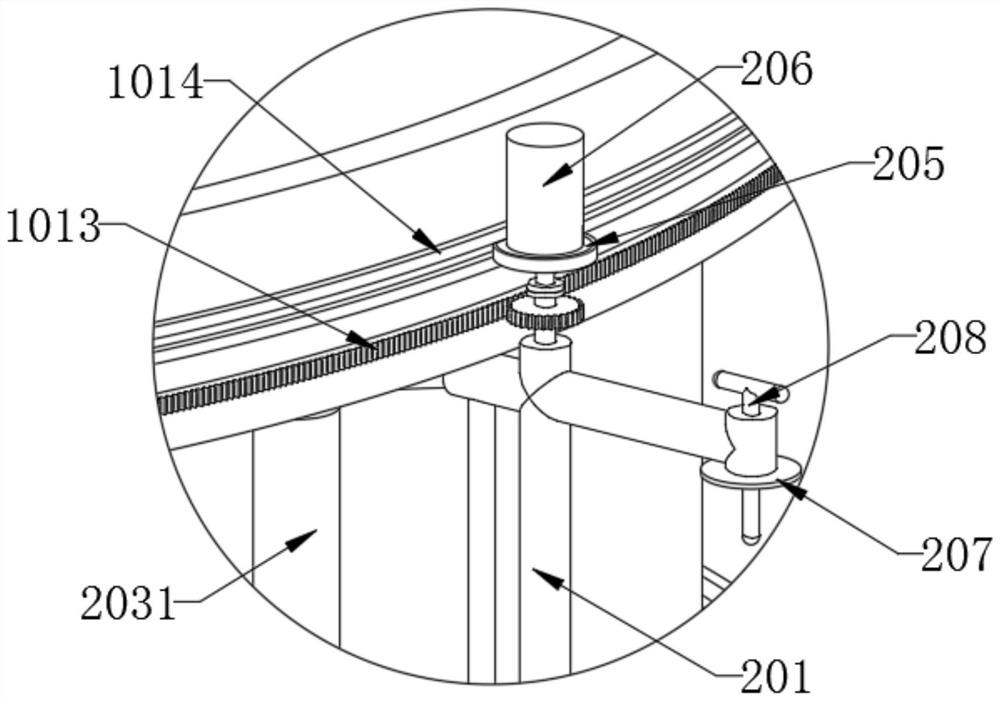

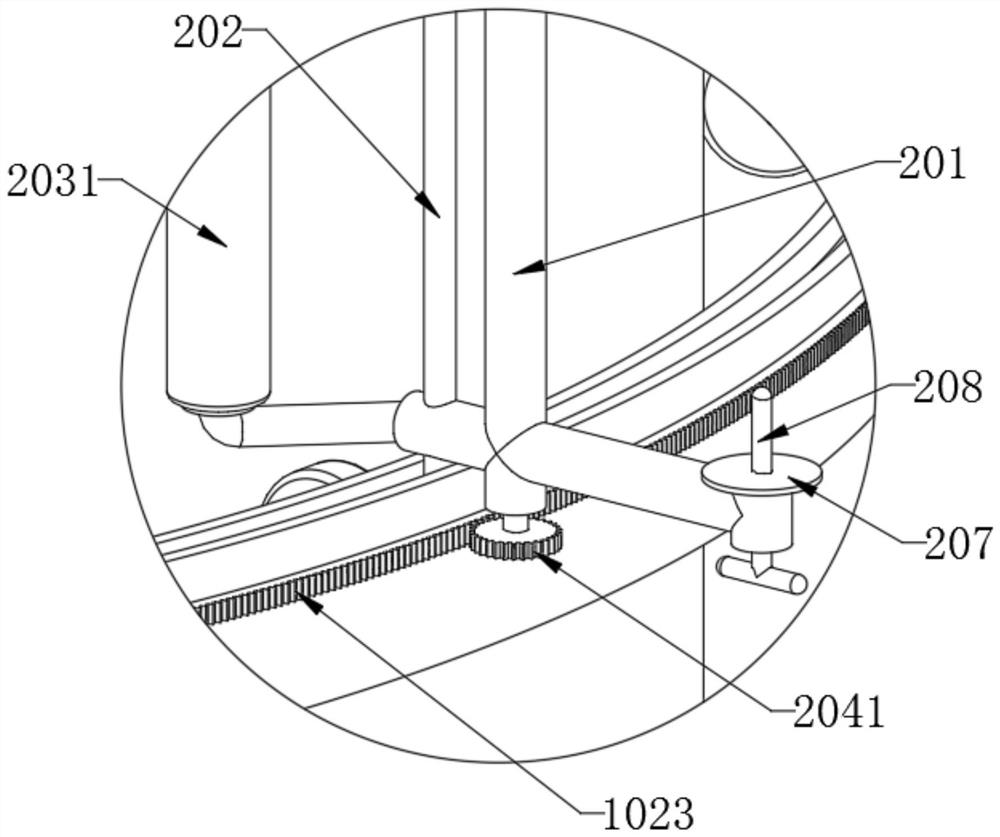

[0032] The present invention provides a wrapping film coating device based on a column tower structure of a building, comprising a snap ring body 1 and a film coating mechanism 2; the snap ring body 1 is composed of an upper snap ring 101, a lower snap ring 102 and a U-shaped connecting rod 103, the upper snap ring 101 and the lower snap ring 102 are respectively sleeved on the outside of the column tower, and the U-shaped connecting rods 103 are provided with four groups and are respectively connected between the outer sides of the upper snap ring 101 and the lower snap ring 102. The inner end of the ring 101 is connected with eight groups of inner guide wheels A1011, the inner guide wheels A1011 are attached to the outer wall of the column tower, the inner end of the lower snap ring 102 is connected with eight groups of inner guide wheels B1021, and the inner guide wheels B1021 are also attached to the column. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com