Pivot steering system and small multi-wheel carrying logistics vehicle

A technology for in-situ steering and logistics vehicles, which is applied in mechanical steering gears, electric steering mechanisms, superstructures of trucks, etc. Small turning radius, easy steering and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

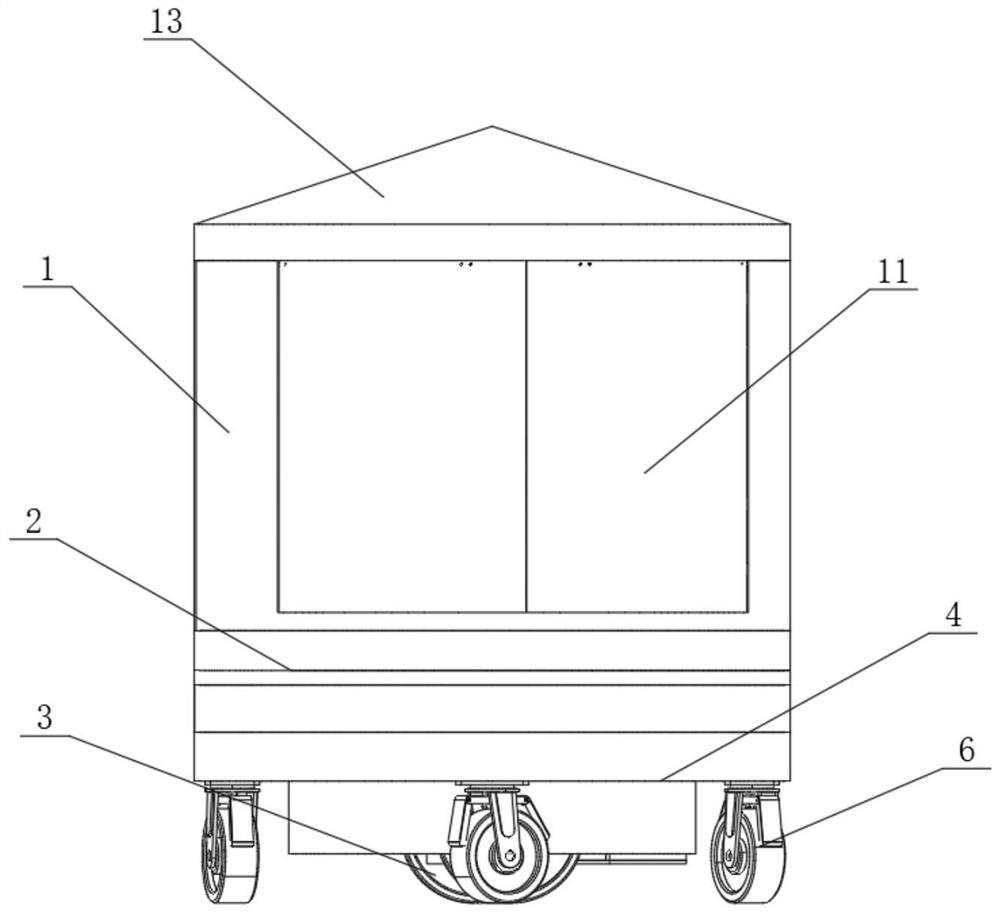

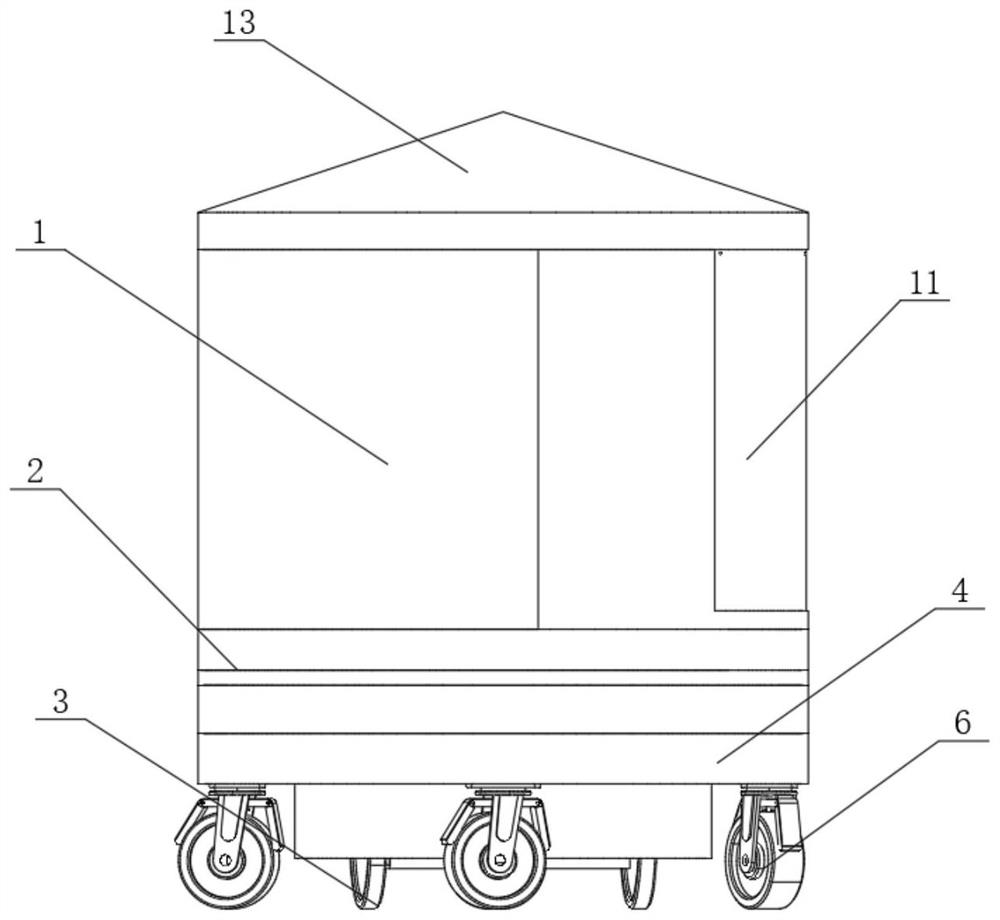

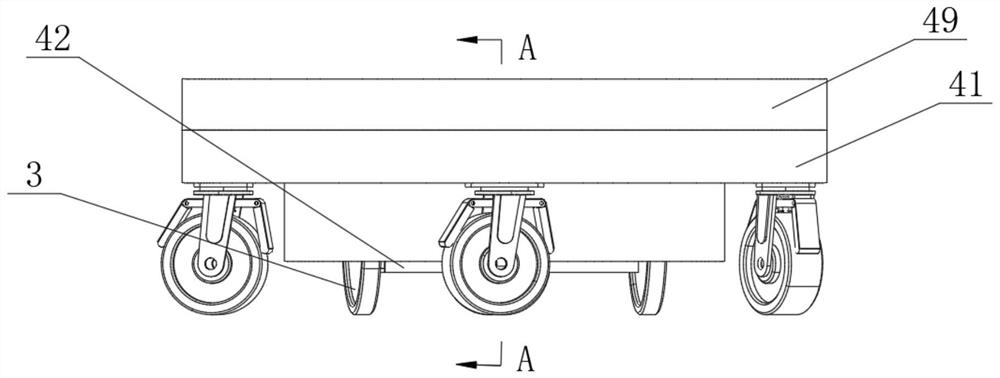

[0052] Figure 1 to Figure 10 An embodiment of a small multi-wheeled logistics vehicle of the present invention is shown. The small multi-wheeled logistics vehicle of this embodiment includes a cabin 1, a cabin rotation system 2 for rotating the cabin 1, a switch or The door opening and closing device 12 for closing the cabin door 11 of the cabin 1 (the door opening and closing device 12 in this embodiment is a planetary gear linkage door opening and closing system), the wheels 3, and the steering drive system for driving the wheels 3 to travel and turn 4. The wheel attachment adaptive adjustment system 5 and the braking system 6 for adjusting the overhang of the wheel 3 are attached. The cabin rotation system 2 is arranged between the cabin 1 and the steering drive system 4 .

[0053] like figure 1 , figure 2 and Figure 15 As shown in the figure, in this logistics vehicle, the cabin rotation system 2 can rotate the cabin 1, and in a narrow space, when the wheels 3 of the...

Embodiment 2

[0100] like Figure 26 and 27 As shown, the logistics vehicle of this embodiment is basically the same as that of the first embodiment, except that the hatch door opening and closing device 12 (the hatch door opening and closing device 12 in this embodiment is a multi-link linkage hatch door opening and closing system) is different.

[0101] The hatch door opening and closing device 12 of this embodiment includes a large center wheel 128 , a small center wheel 129 , a planetary wheel 130 , a planet carrier 131 , a third drive assembly 132 and a connecting frame 133 , and a large center wheel 128 , which are arranged on the top of the vehicle cabin 1 . It is rotatably arranged on the top of the cabin 1 and is fixedly connected with one of the cabin doors 11. The small central wheel 129 is fixedly connected with the other cabin door 11 through the connecting frame 133. Between the center wheels 129 and meshing with the two, one end of the planet carrier 131 is rotatably connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com