Vacuum servo assistance system, vehicle control method, storage medium and vehicle

A vacuum servo and booster system technology, applied in the field of vehicles, can solve problems such as poor braking effect of vehicles, potential safety hazards of vehicles, and failure of vacuum boosters to reach the highest vacuum degree, so as to reduce potential safety hazards, increase boosting effect, and improve control effect of animation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present disclosure will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present disclosure, but not to limit the present disclosure.

[0031] In the following description, words such as "first" and "second" are only used for the purpose of distinguishing descriptions, and cannot be understood as indicating or implying relative importance, nor can they be understood as indicating or implying order.

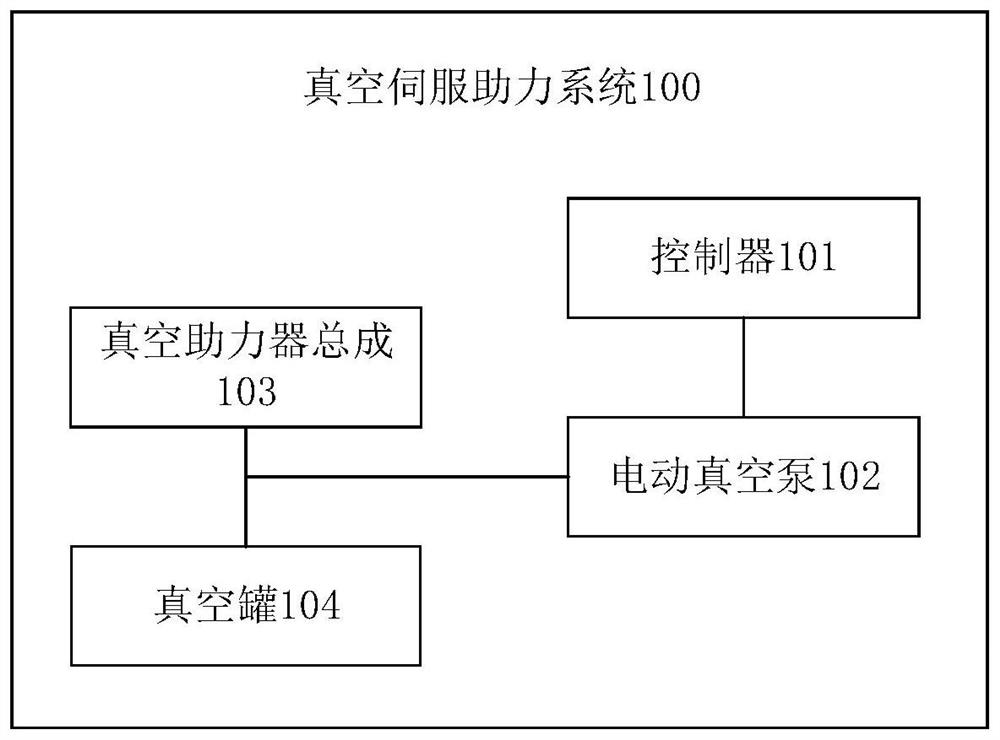

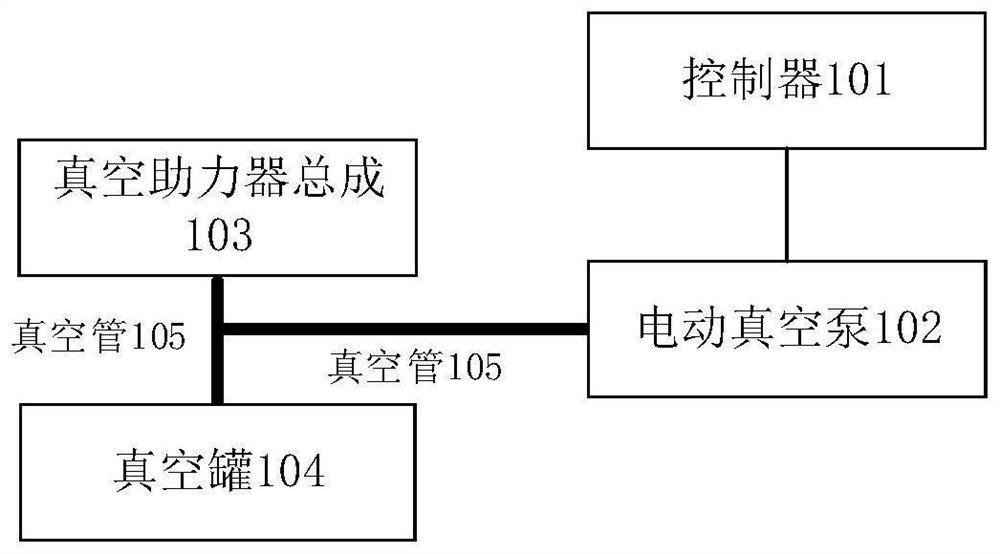

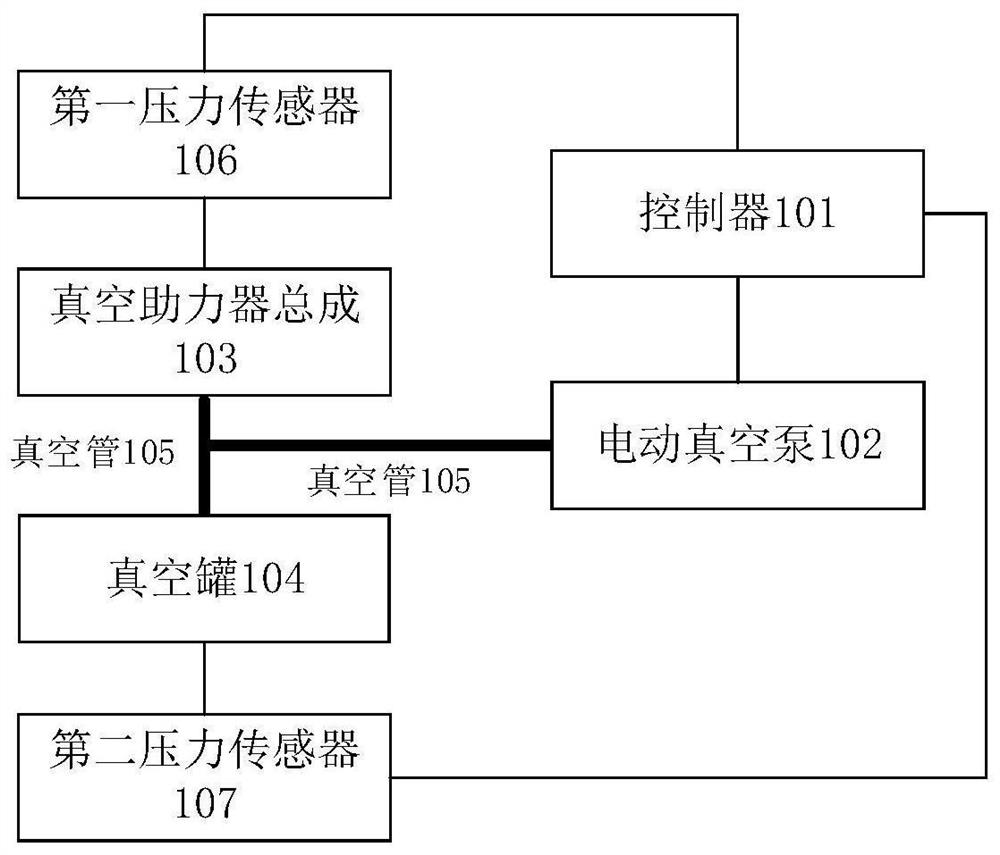

[0032] First, the application scenarios of the present disclosure will be described. The present disclosure can be applied to vehicles using a vacuum servo booster system. Currently, electric vacuum pumps are used as vacuum sources for new energy electric vehicles to extract air from the vacuum booster assembly, and some models will add a vacuum tank as a vacuum reserve. When the driver brakes in an emer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com