System for automatically controlling thickening parameters in photoelectric monitoring thickening process and corresponding thickener

A photoelectric detection and density technology, applied in separation methods, precipitation separation, sedimentation tanks, etc., can solve the problems of inability to intelligently control density parameters, failure of concentration detection instruments, distortion of detection results, etc., so as to ensure the concentration effect, and the detection data is effective and reliable. , avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

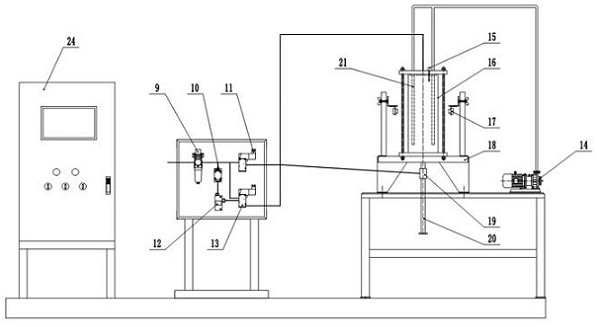

[0020] A system for automatically controlling thickening parameters in photoelectric monitoring thickening process (abbreviation: photoelectric monitoring automatic control system), the main points of the innovative overall implementation plan are: 1. On the basis of the existing thickener vacuum see-through container equipment, add photoelectric detection Instrument 17, and cancel the existing concentration detection device, the photoelectric detection instrument 17 can monitor the thickening process (including sedimentation speed and time) online in real time, and transmit the detection data to the PLC control system 24; 2. Use the PLC control system 24 to replace the current Some non-intelligent electrical control systems, PLC control system 24 real-time dynamic comparison of detection data and design parameters, intelligent control of dense parameters - timely adjustment of the feed amount and the reasonable amount of flocculant, to avoid the waste of flocculant, to ensure t...

Embodiment 2

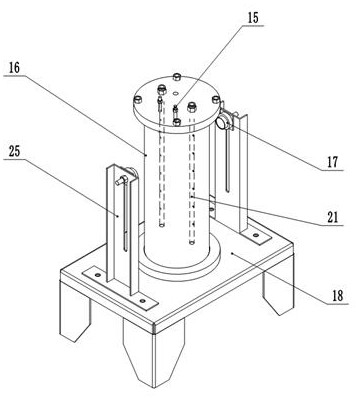

[0030] A thickener, that is, an automatic thickener, uses the system for automatically controlling the thickening parameters of the photoelectric monitoring thickening process (abbreviated as: photoelectric monitoring automatic control system) provided by the present invention; 2, scraper shaft 3, scraper 4), photoelectric monitoring automatic control system (the present invention) and other components; it is suitable for the concentration of suspension with low concentration - the solid content of 10% to 20% Suspension slurry (suspension) is concentrated into underflow sediment with a solid content of 45% to 55% by gravity sedimentation, which is used for subsequent treatment by terminal dewatering equipment such as filter presses.

[0031] The photoelectric monitoring automatic control system is mainly equipped with a vacuum perspective container (including a pocket transparent container 16 and its accessories, a container cleaning pump 14, a pneumatic control system), a phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com