Maillard intermediate flavor material for improving flavor and color quality of soda biscuits

A technology for soda biscuits and intermediates, applied in the field of Maillard intermediate flavors, can solve the problems of insufficient color and luster, loss of aroma, etc., and achieve the effects of improving monotonous flavor, improving acceptability, and high thermal reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Weigh 17.8g of alanine and 72g of glucose, dissolve in 1000g of deionized water, adjust the pH to 7.0, place the mixed solution in a rotary evaporation flask, and react at 90°C and 25mbar for 25min to obtain Emera The German intermediate is the mixture of the main products. Adjust the pH of the Maillard intermediate mixture to 3, and use Dowex 50WX4 H+ type cation exchange resin for separation and purification to obtain pure alanine-glucose deoxyamino sugar. .

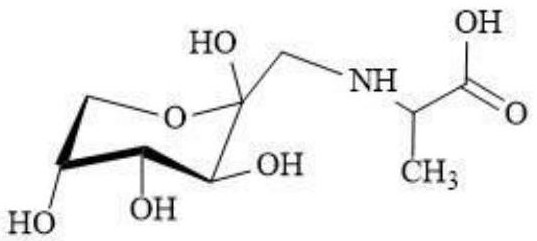

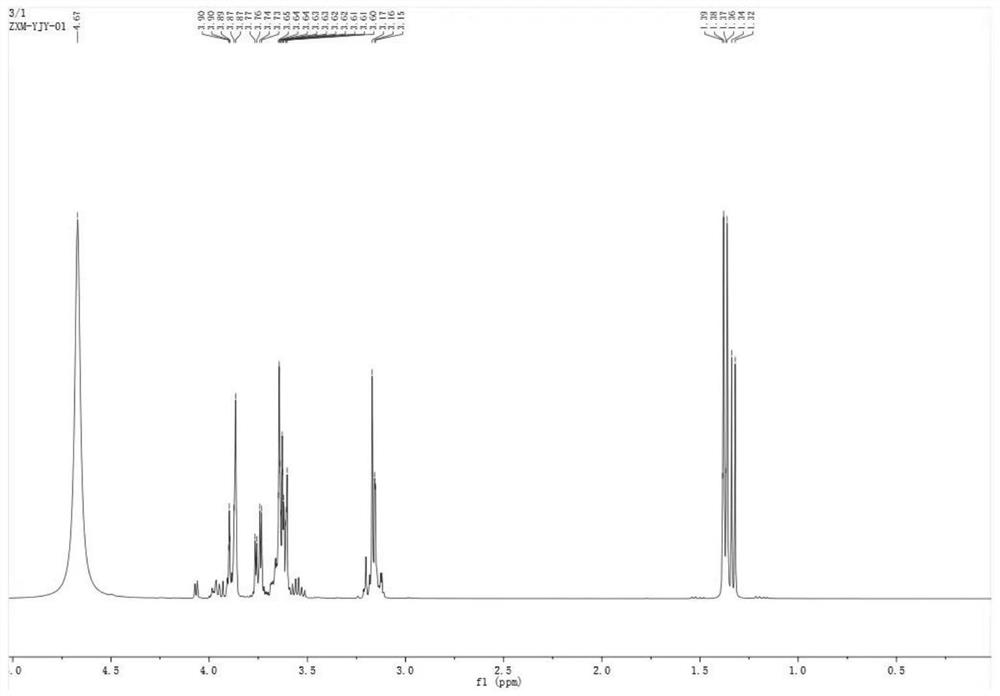

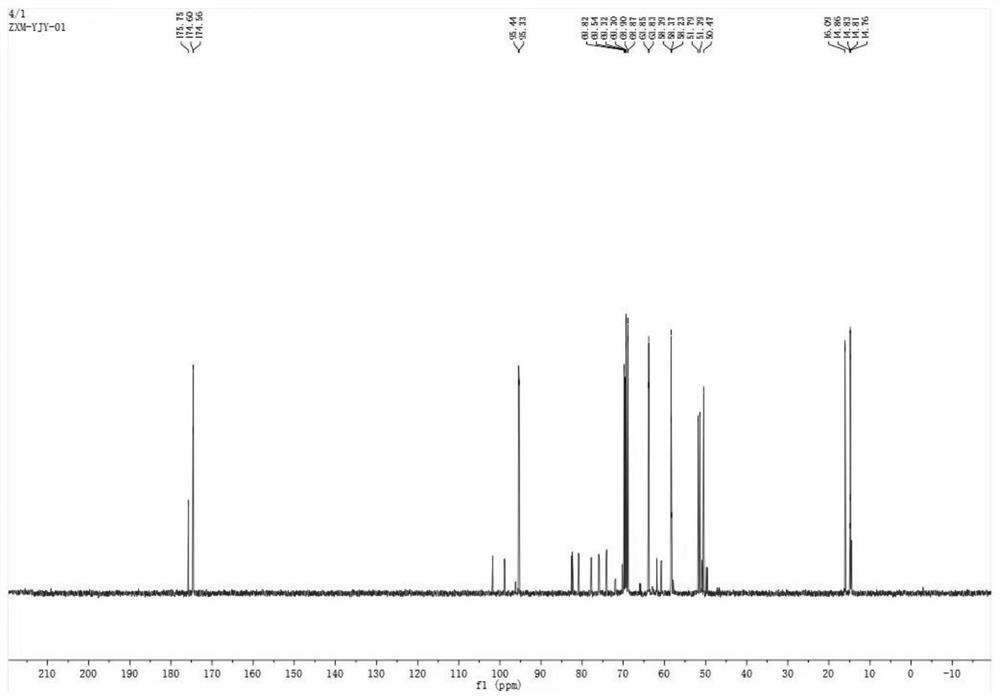

[0049] The resulting pure powder was completely dissolved in heavy water and transferred to an NMR tube. Using an all-digital nuclear magnetic resonance spectrometer and a 5mm PABBO probe, the 1H-NMR spectrum and the 13C-NMR spectrum were measured at 298K, and the nuclear magnetic resonance spectrum was obtained as follows figure 2 and image 3 As shown, it is confirmed that it is a deoxyamino sugar of alanine-glucose system, and its molecular structure in the aqueous phase is as follows Figure 4 shown.

Embodiment 2

[0051] The powdered intermediate flavoring material obtained in the above Example 1 was applied to the production of soda biscuits.

[0052] Mix 100g of low-gluten flour, 3g of baking powder, 2g of yeast, 0.6g of baking soda and 0.1g of intermediate flavoring (0.1%, w / w flour) evenly, add 40g of milk and 20g of butter, roll and knead into a dough, put in Cover and proof at room temperature for 30 minutes, perform secondary rolling, characterization, and piercing, and bake at 150° C. for 20 minutes to obtain soda biscuits with Maillard intermediates added.

[0053] Sensory evaluation of soda biscuits was carried out, and the results are shown in Table 1. The characteristic volatile flavor components of soda biscuits were analyzed by gas chromatography-mass spectrometry, and the results are shown in Table 2. The color difference analysis of soda biscuits was carried out using a high-precision spectrophotometer, and the results are shown in Table 3.

Embodiment 3

[0055] The powdered intermediate flavoring material obtained in the above Example 1 was applied to the production of soda biscuits.

[0056] Mix 100g of low-gluten flour, 3g of baking powder, 2g of yeast, 0.6g of baking soda and 0.3g of intermediate flavoring (0.3%, w / w flour) evenly, add 40g of milk and 20g of butter, roll and knead to form a dough. Cover and proof at room temperature for 30 minutes, perform secondary rolling, characterization, and piercing, and bake at 150° C. for 20 minutes to obtain soda biscuits with Maillard intermediates added.

[0057] Sensory evaluation of soda biscuits was carried out, and the results are shown in Table 1. The characteristic volatile flavor components of soda biscuits were analyzed by gas chromatography-mass spectrometry, and the results are shown in Table 2. The color difference analysis of soda biscuits was carried out using a high-precision spectrophotometer, and the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com