Flexible electrode, preparation method thereof and massage instrument

A flexible electrode and elastic technology, applied in electrodes, electrotherapy, cable/conductor manufacturing, etc., can solve the problems of poor air permeability and elasticity of PU conductive film, and achieve the effect of improving air permeability, improving conductivity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

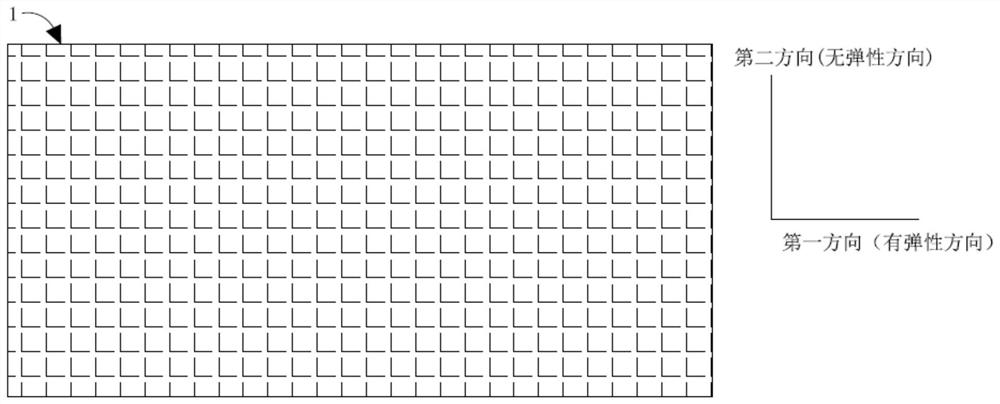

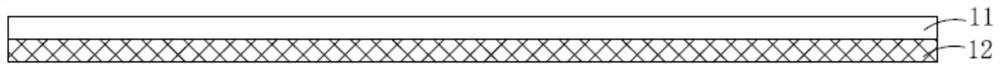

[0070] In a second aspect, an embodiment of the present application provides a method for preparing the above-mentioned flexible electrode 1, including the following steps:

[0071] A conductive cloth is provided as the bottom layer 12 , a conductive paste is coated on the conductive cloth along the second direction, and the surface layer 11 is formed after drying at 100° C.˜200° C., so as to obtain the flexible electrode 1 .

[0072] Through the above preparation method, the conductive paste is coated on the conductive cloth along the designated second direction and dried, so as to obtain a material that can meet the requirements of good electrical conductivity, good flexibility, good bonding strength, high reliability, good air permeability and certain elasticity at the same time. Flexible electrode 1. The preparation method has the advantages of simple operation steps and easy industrial application. In the preparation method, the conductive paste is coated along the inelas...

preparation example 1

[0081] This preparation example provides a conductive paste, in parts by mass, the conductive paste includes: 50 parts of polyurethane resin, 26 parts of solvent, 8 parts of conductive filler, 0.5 part of leveling agent, and 0.5 part of dispersant. The conductive filler is graphene oxide, the leveling agent is BYK-323, the dispersant is an anionic dispersant, and the solvent is N,N-dimethylformamide.

[0082] The preparation method of the conductive paste comprises the following steps: adding polyurethane resin, conductive filler, leveling agent and dispersant into a solvent according to the above-mentioned parts by mass, stirring evenly and defoaming to obtain conductive paste, and then adding conductive paste Coated on conductive cloth.

preparation example 2

[0084] The difference between this preparation example and preparation example 1 is that the types and amounts of the raw material components in the conductive paste are different: 60 parts of polyurethane resin, 41 parts of solvent, 12 parts of conductive filler, 1 part of leveling agent, and 1 part of dispersant . Among them, the conductive filler is carbon black, the leveling agent is BYK-352, the dispersant is a polymer type dispersant, and the solvent is acetone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com