Intelligent automatic control system for cleaning workshop

An automatic control system and purification workshop technology, applied in the field of workshop purification, can solve the problems of inconvenient cleaning, poor cleaning effect, lack of automatic filter screen, etc., and achieve the effect of safe and convenient use, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

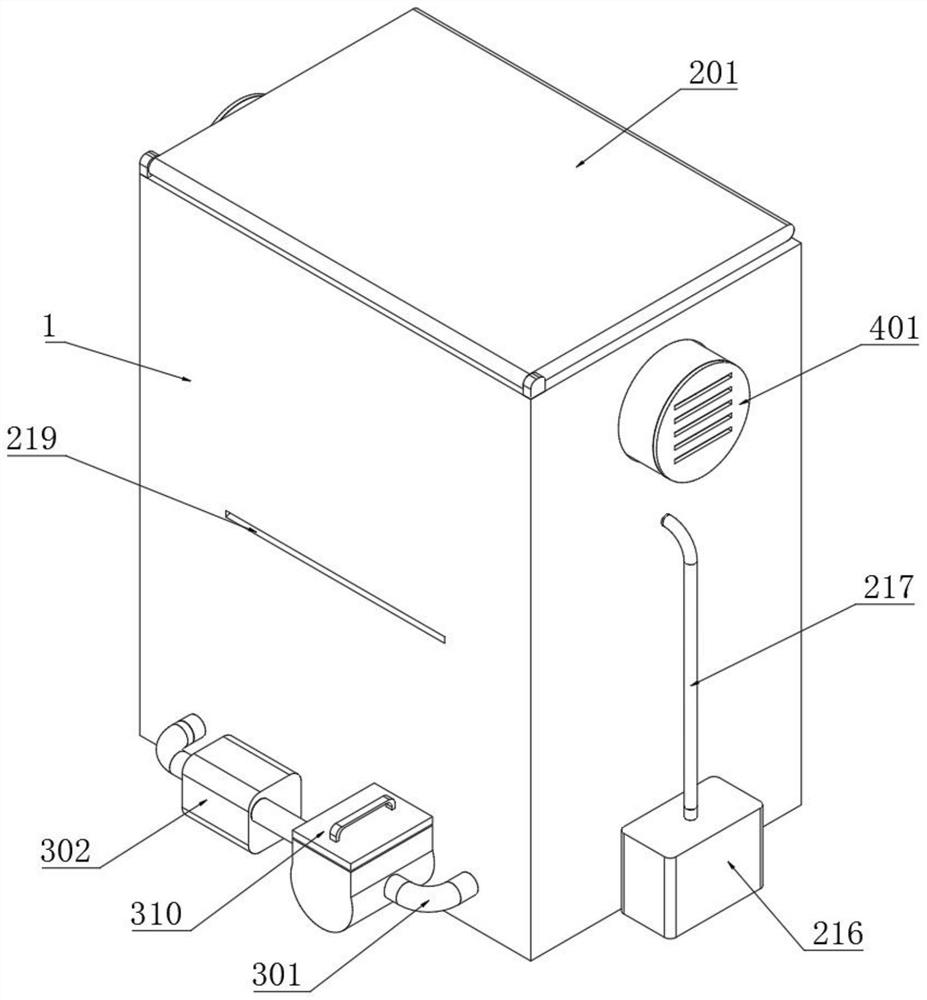

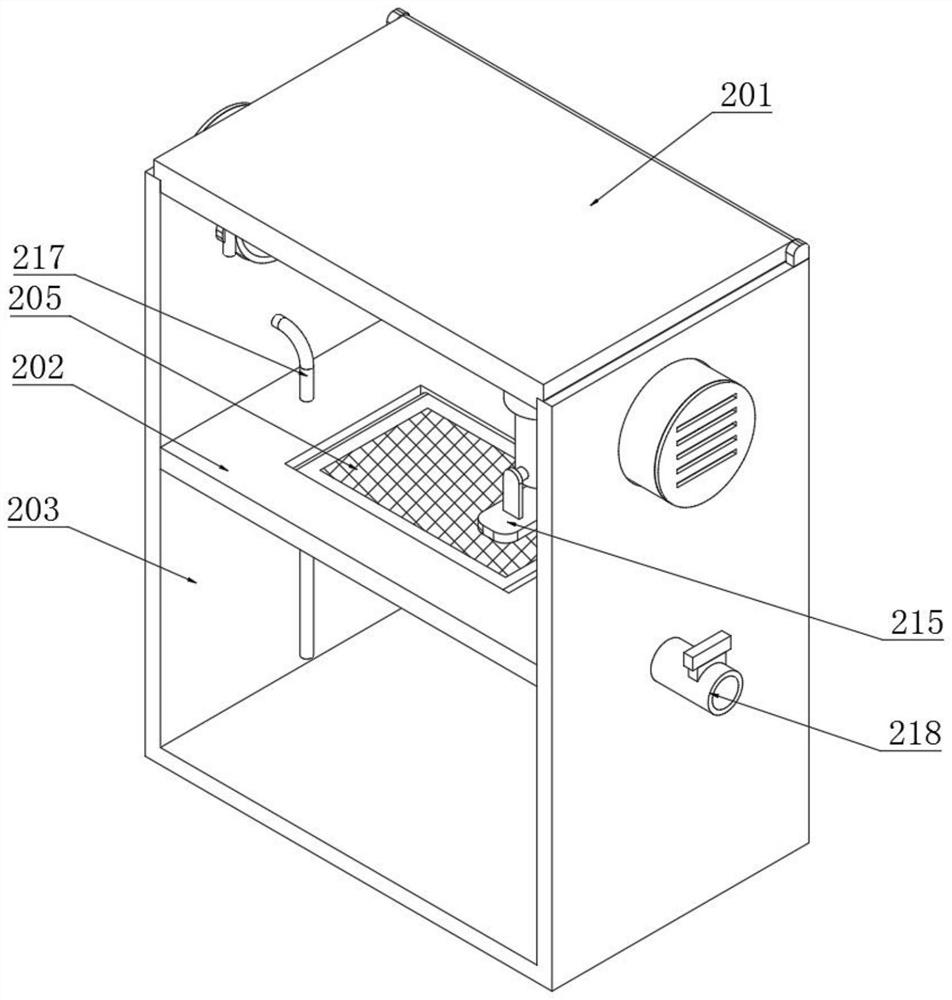

[0040] Example: as Figure 1-9 As shown, the present invention provides a technical solution, an intelligent automatic control system for a purification workshop, including a purification box 1, an automatic cleaning mechanism 2, and an air pump 216 to introduce external air into the water through the air intake pipe 217, so that the water storage chamber 203 A large amount of foam appears inside, so that the first filter screen 205 is shaken, making cleaning more clean;

[0041]In the backflow filter mechanism 3, the water flow contacts the second filter screen 308 to drive the installation frame 307 to rotate, and due to the function of the second filter screen 308, it is convenient to filter the impurity particles in the water;

[0042] In the disassembly mechanism 4 , when the rotating rod 408 slides out of the guide groove 407 , the restriction of the connecting plate 406 is released, and it is convenient for the staff to disassemble the guide cylinder 401 and repair the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com