Device and method for measuring yield stress of viscous debris flow

A yield stress and measuring device technology, applied in the fields of geological engineering and debris flow disaster prevention, can solve the problems of inability to measure the yield stress of full-size debris fluid, poor repeatability of measurement results, time-consuming viscous debris flow, etc., and achieve stable calculation results and test results. Small sample, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

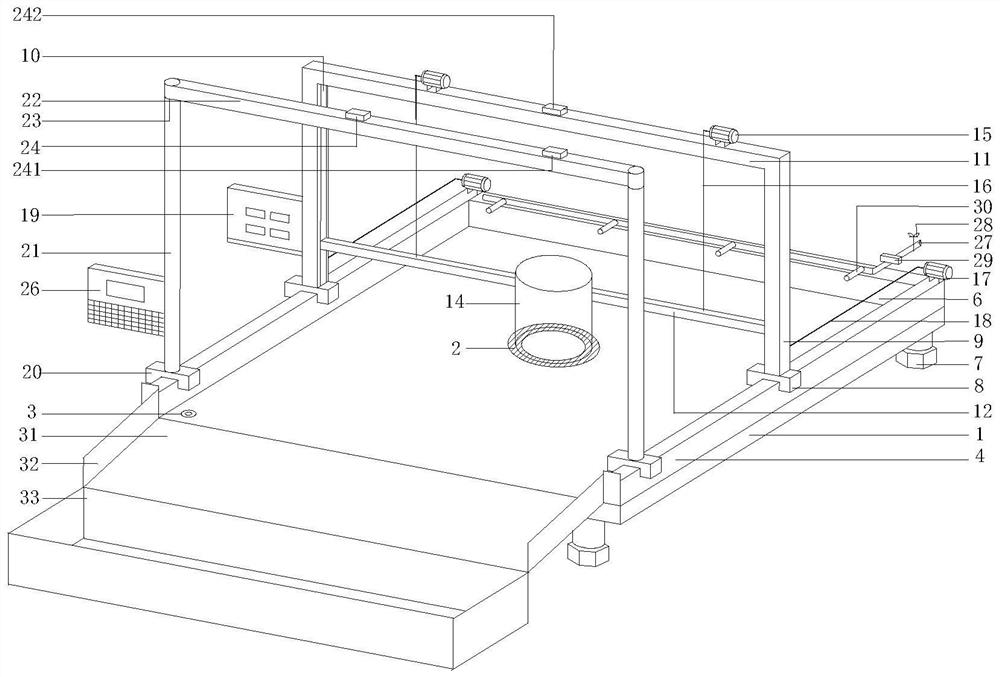

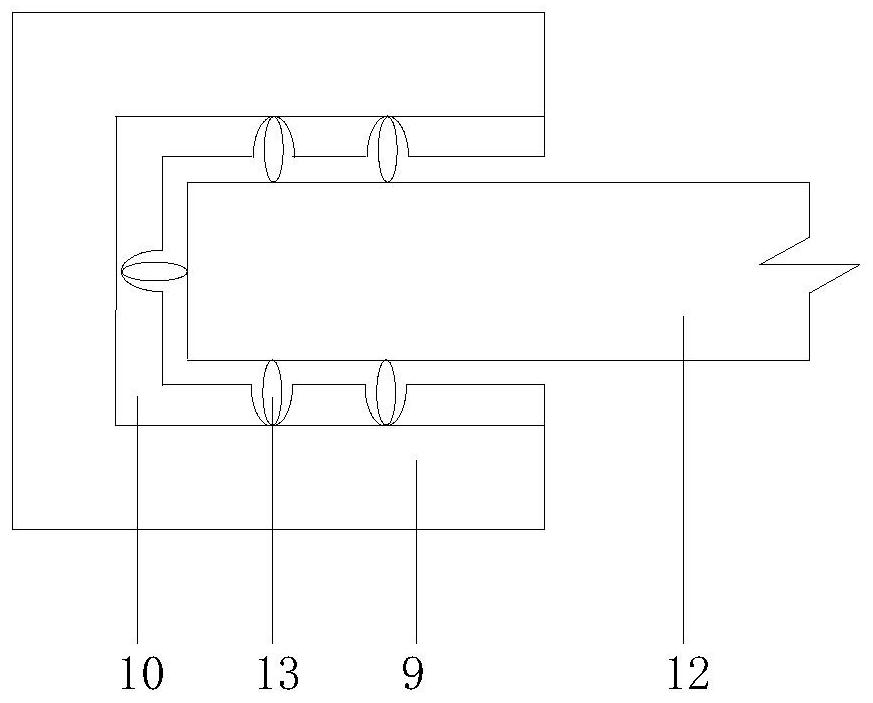

[0062] Example 1: as Figure 1-10 As shown, the viscous debris flow yield stress measurement device includes a yield stress measurement platform, a slump-expansion bucket lifting device, a traction device, a yield stress measurement and analysis device, and a cleaning and recovery device;

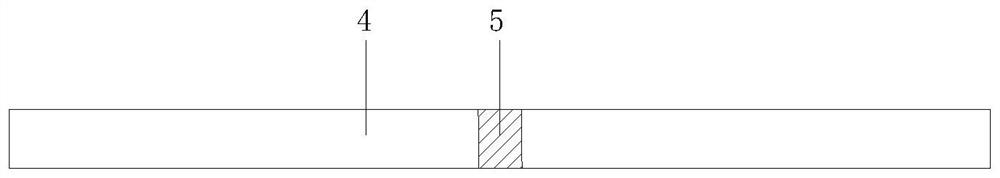

[0063] The yield stress measurement platform includes a rectangular flat plate 1, an annular de-energized electromagnet 2, a bubble level 3, a rectangular guide rail 4, a rectangular magnet 5, a transverse baffle 6 and a leveling foot 7; the lower left corner of the rectangular flat plate 1 is provided with a The bubble level 3 can be centered by adjusting the length of the leveling feet 7; the annular de-energized electromagnet 2 is embedded in the center of the rectangular flat plate 1, and is connected to an independent power supply unit of the power supply device 19 through a wire, It has magnetism in the case of power-off, but has no magnetism in the case of power-on; the rectangular g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com