Hydraulic side opening type turnover elevator

A hydraulic and elevator technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of inability to guarantee personnel safety, failure of mechanical elevators to adapt to various specifications underground, hidden safety risks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

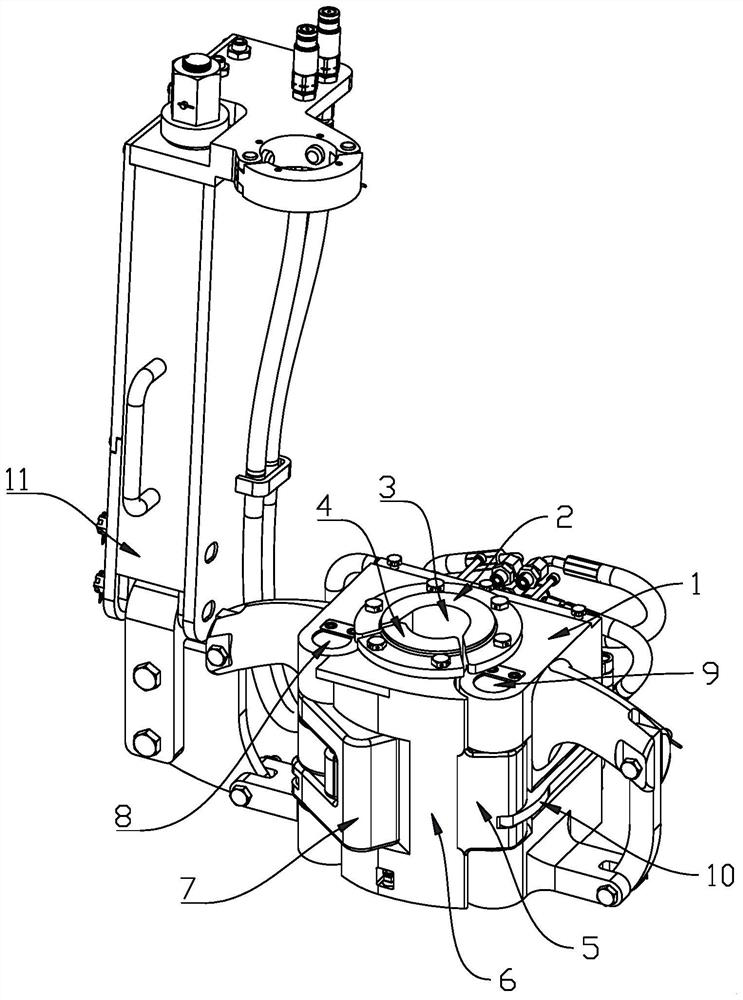

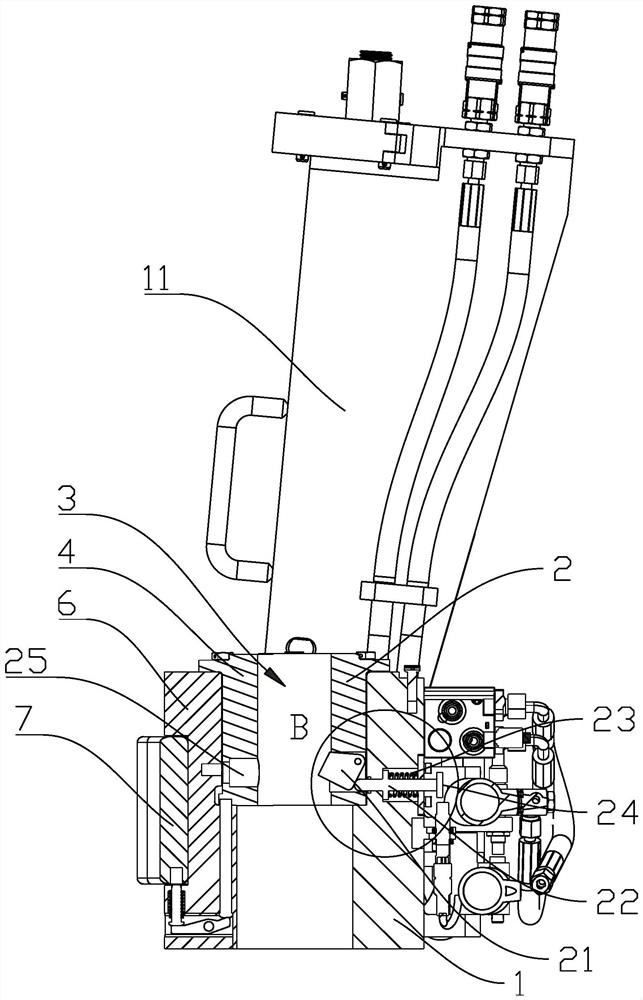

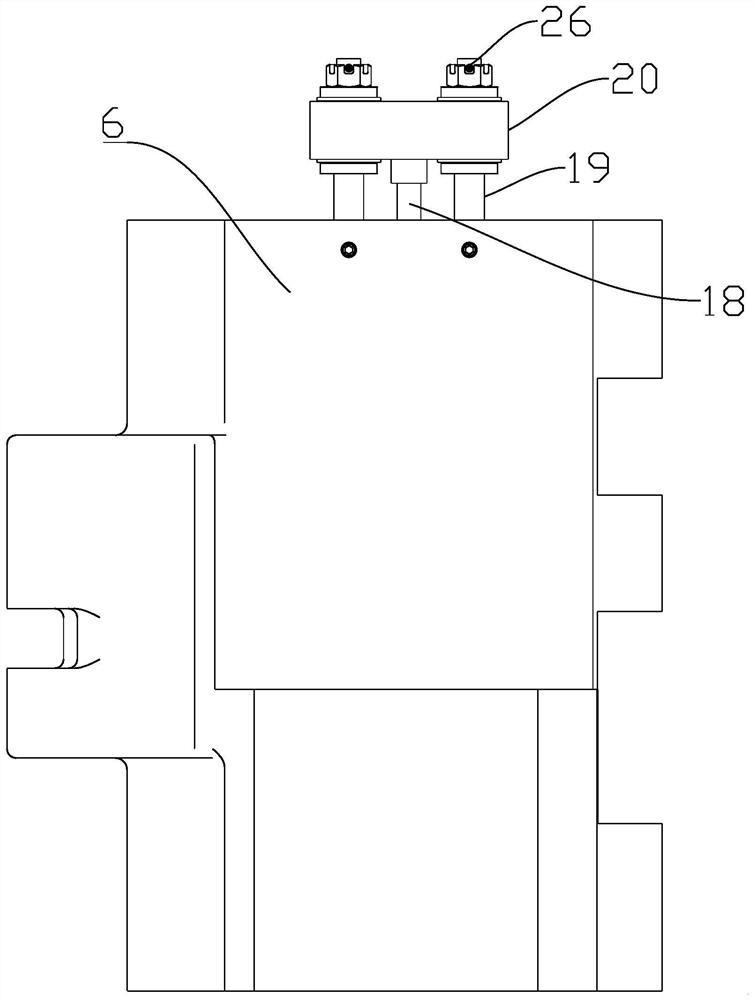

[0039] Please refer to figure 1 and figure 2 , figure 1 Shown is a schematic diagram of a three-dimensional structure of an embodiment of the present invention; figure 2 It is a cross-sectional view of an embodiment of the present invention. This embodiment provides a hydraulic side-opening flip elevator, which includes a flip assembly 11, a main assembly, a drive assembly and a control unit. The above-mentioned main assembly is the main component for hoisting the oil pipe and other pipe body equipment, which can clamp or loosen the pipe body equipment such as the oil pipe. The above-mentioned inversion assembly 11 is used to realize the inversion of the main body assembly, so as to achieve the purpose of inverting the pipe body equipment such as the oil pipe on the main body assembly. The above-mentioned driving assembly is used to drive the action of the main assembly to complete the clamping or loosening of the tubing and other equipment. The above-mentioned control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com