Original bamboo and recombined bamboo mixed one-way plate unit, composite floor and construction method

A technology of recombining bamboo and one-way panels, which is applied in the processing of floors, building materials, construction, etc., can solve problems limited to non-structural fields, and achieve the effects of simple and easy installation process, low cost and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

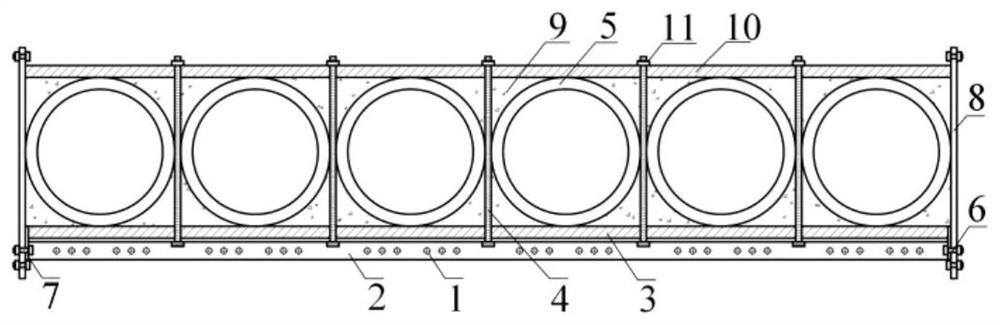

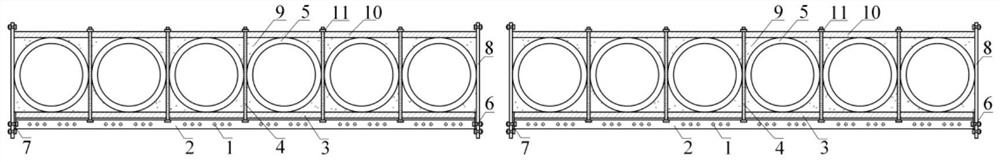

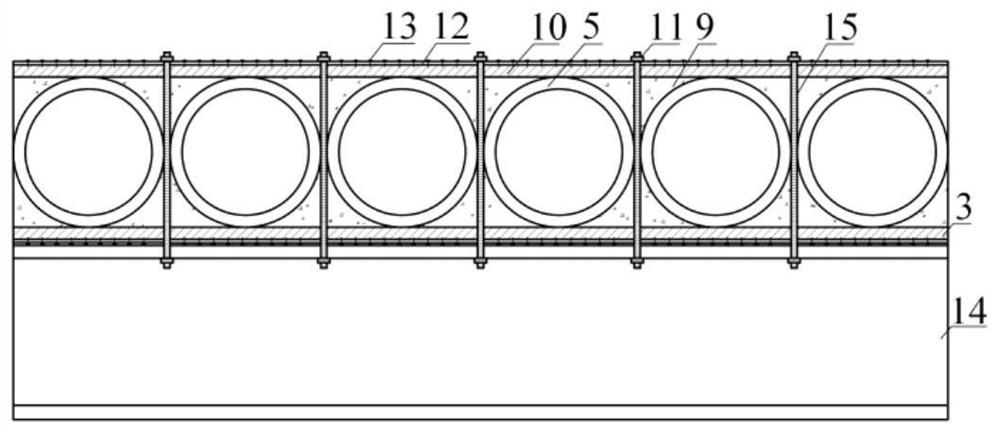

[0052] Example 1: Fully bolted bamboo composite floor

[0053] see Figure 1 to Figure 5 , the fully bolted bamboo composite floor proposed in the present invention mainly includes the bottom angle steel, the upper and lower reorganized bamboo boards, the original bamboo, the light desulfurization gypsum modified material, the long screw and the bolts and other connecting parts. The angle steel 2 is arranged on the bottom surface at a distance of 600mm along the longitudinal direction of the floor slab, and then the reconstituted bamboo base plate 3 is laid on the angle steel 2, and the long screw 4 with a nut passes through the back of the horizontal angle steel 2 and the reorganized bamboo base plate 3 from bottom to top, and then along the The original bamboo 5 is arranged between the long screws 4 with nuts in the horizontal direction, and the end plates 7 and the lateral end plates 8 are connected by bolts 6. At the same time, a template is installed around the rest of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com