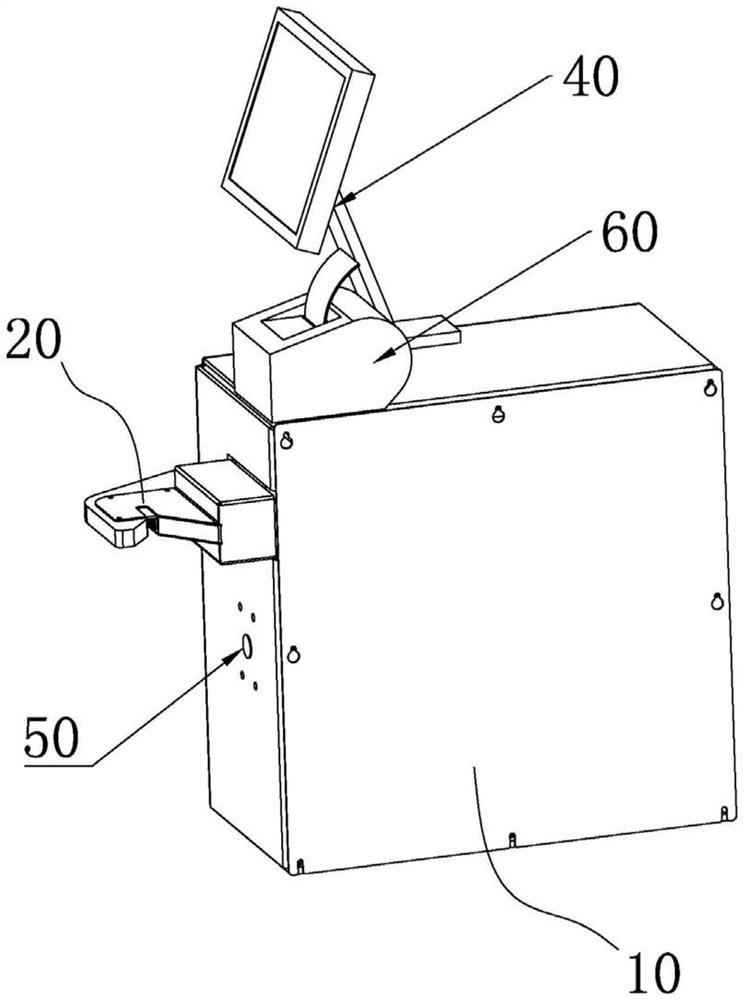

Intelligent weighing and sealing all-in-one machine

An intelligent weighing and all-in-one machine technology, which is applied in packaging sealing/fastening, transportation packaging, packaging, etc., can solve the problems of single function, only edge banding function, and low efficiency of ultrasonic sealing machine, so as to achieve effortless operation, Easy to use and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

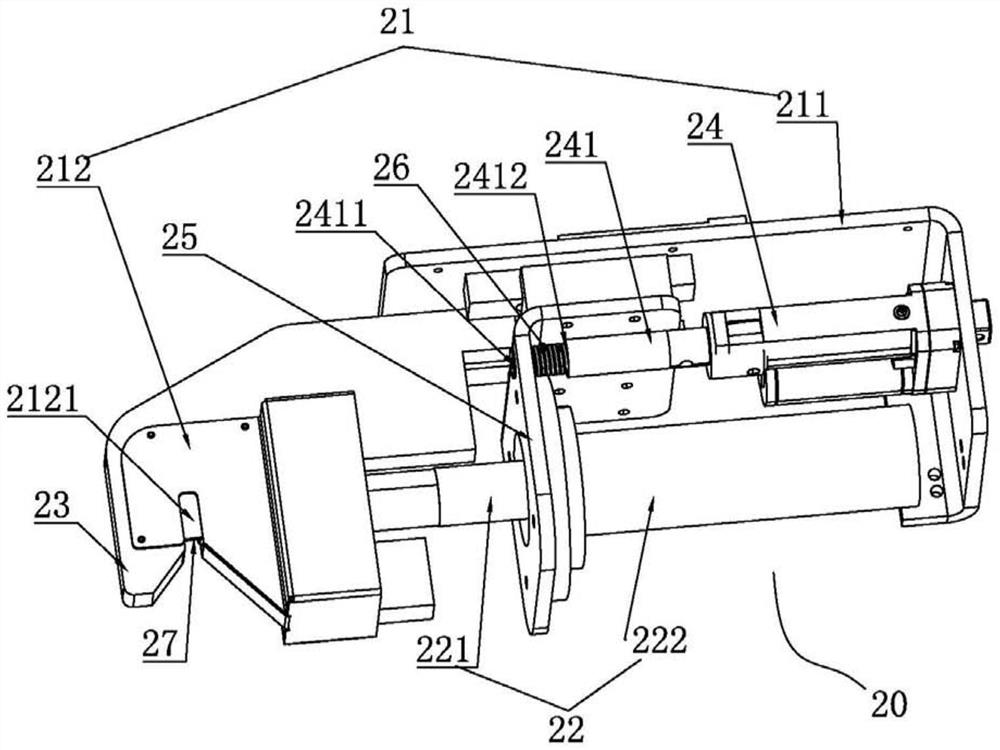

Embodiment 1

[0057] like Figure 4 As shown, the weighing unit 30 is elongated and extends in a horizontal first direction, one end of which is fixed on the rack 10 , and the other end is fixed on the bottom plate 2113 of the fixing frame 21 . In this embodiment, the weighing unit 30 can support the weight of the ultrasonic sealing unit 20 and its attachments, the structure of the ultrasonic sealing unit 20 is more stable, and the structure is simple and practical.

Embodiment 2

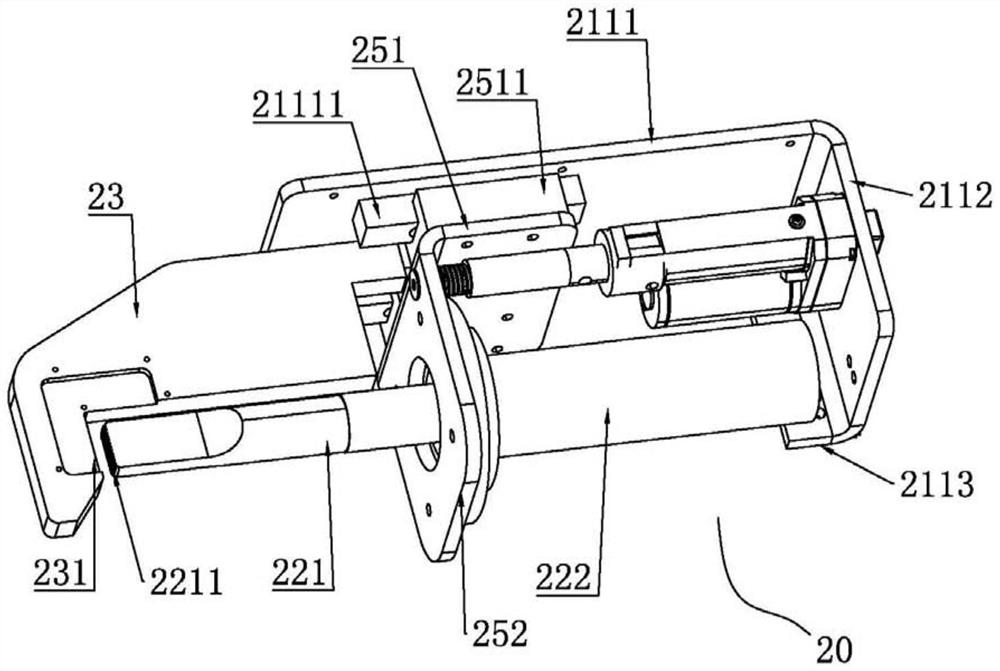

[0059] like Figure 5 As shown, the rack 10 is provided with a first wall 11 extending along the first direction and perpendicular to the first sealing surface 2211, the first wall 11 is parallel and opposite to the second wall 2111 of the body 211 of the fixing frame 21; the weighing unit 30 is a long strip, which is installed between the first wall 11 and the second wall 2111 , one end of which is fixed to the first wall 11 , and the other end is fixed to the second wall 2111 . In this embodiment, the ultrasonic sealing unit 20 can apply an elastic deformation force to the weighing unit 30 without occupying the space below the ultrasonic sealing unit 20, and the structure is simple and practical.

Embodiment 3

[0061] like Image 6As shown, the weighing unit 30 is elongated and extends along the first direction. One end of the weighing unit 30 is fixed to one end of the rack 10 away from the interval, and the other end is fixed to the end of the fixing frame 21 away from the interval. Specifically, one end of the weighing unit 30 is fixedly connected to the third wall 2112 , and the other end is fixedly connected to a wall of the rack 10 that is parallel and opposite to the third wall 2112 . In this embodiment, the ultrasonic sealing unit 20 can apply an elastic deformation force to the weighing unit 30 without occupying the space below the ultrasonic sealing unit 20, and the structure is simple and practical.

[0062] The working process is as follows:

[0063] In the initial state, the first sealing surface 2211 and the second sealing surface 231 are away from each other and the space between them is open in the second direction. The sealing member, that is, the opening of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com