Automated analyzer

An automatic analysis device, a part of the technology, is applied in the direction of measurement device, analysis material, material analysis by optical means, etc., can solve the problems of reduced precision or accuracy, unable to obtain the quantitative effect of 2-wavelength measurement method, etc., and achieves clear effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

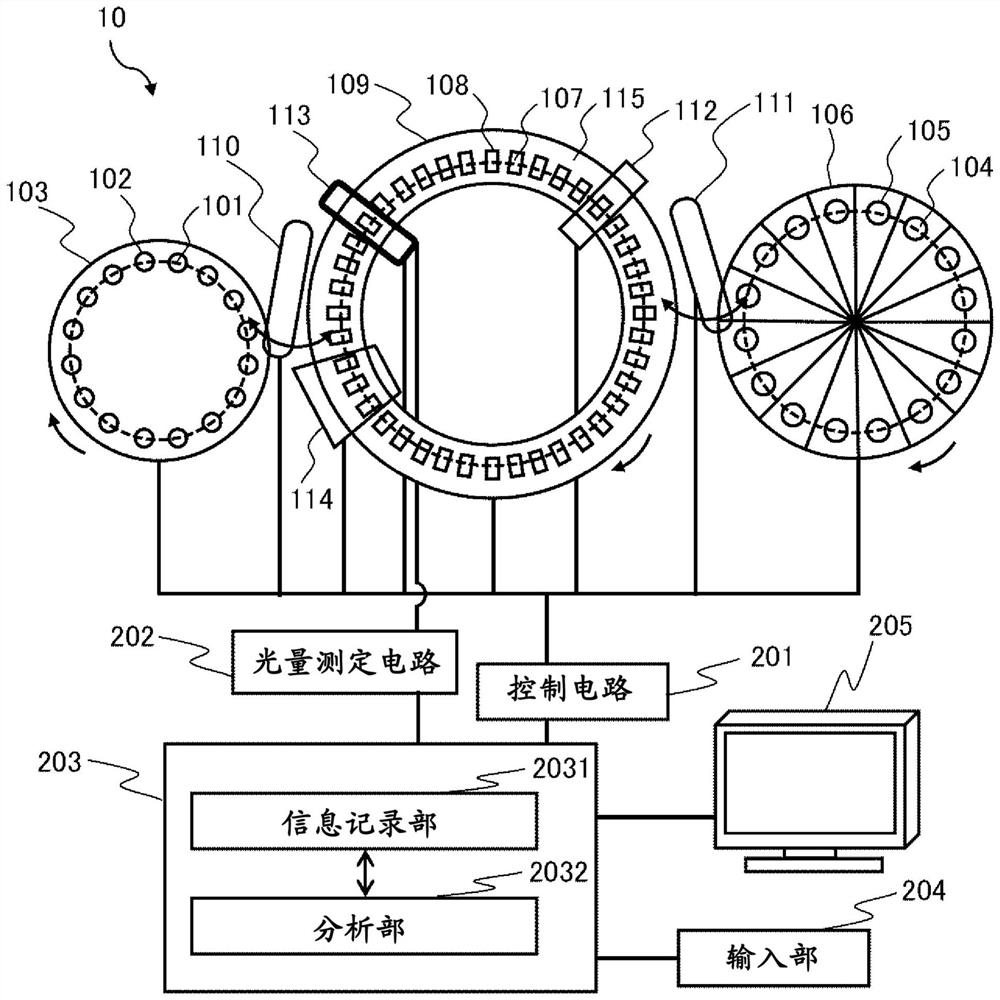

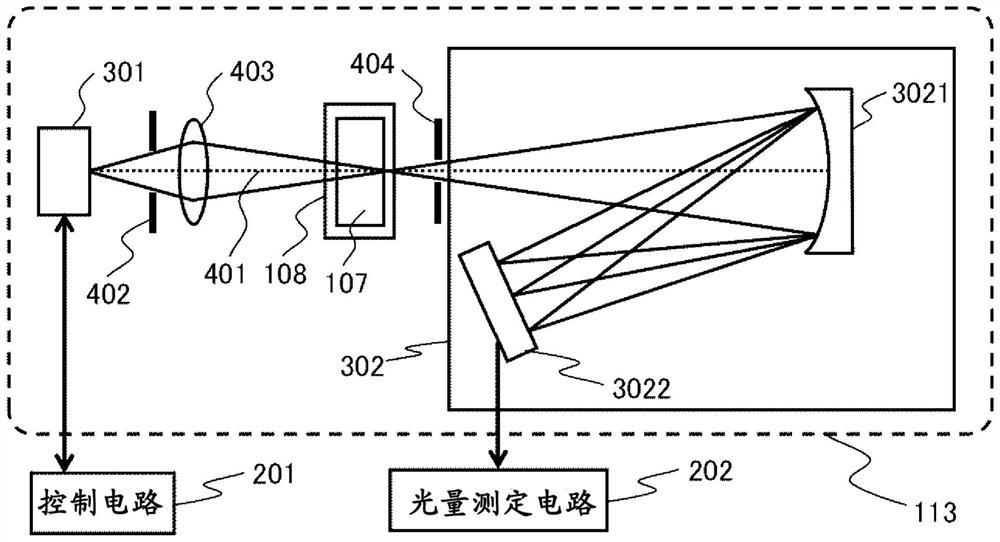

[0034] figure 1 It is a schematic diagram which shows the whole structure of the automatic analyzer 10 which concerns on Embodiment 1 of this invention. The automatic analyzer 10 performs measurement by irradiating a sample with light. The automatic analyzer 10 includes a sample disk 103 , a reagent disk 106 , a reaction disk 109 , a dispensing mechanism, a control circuit 201 , a light quantity measurement circuit 202 , a data processing unit 203 , an input unit 204 , and an output unit 205 .

[0035] The dispensing mechanism moves the sample and the reagent between the disks. The control circuit 201 controls each disk and the dispensing mechanism, and the light quantity measuring circuit 202 measures the absorbance of the reaction solution. The data processing unit 203 processes the data measured by the light quantity measurement circuit 202 . The input unit 204 and the output unit 205 are interfaces with the data processing unit 203 . The dispensing mechanism includes a...

Embodiment approach 2

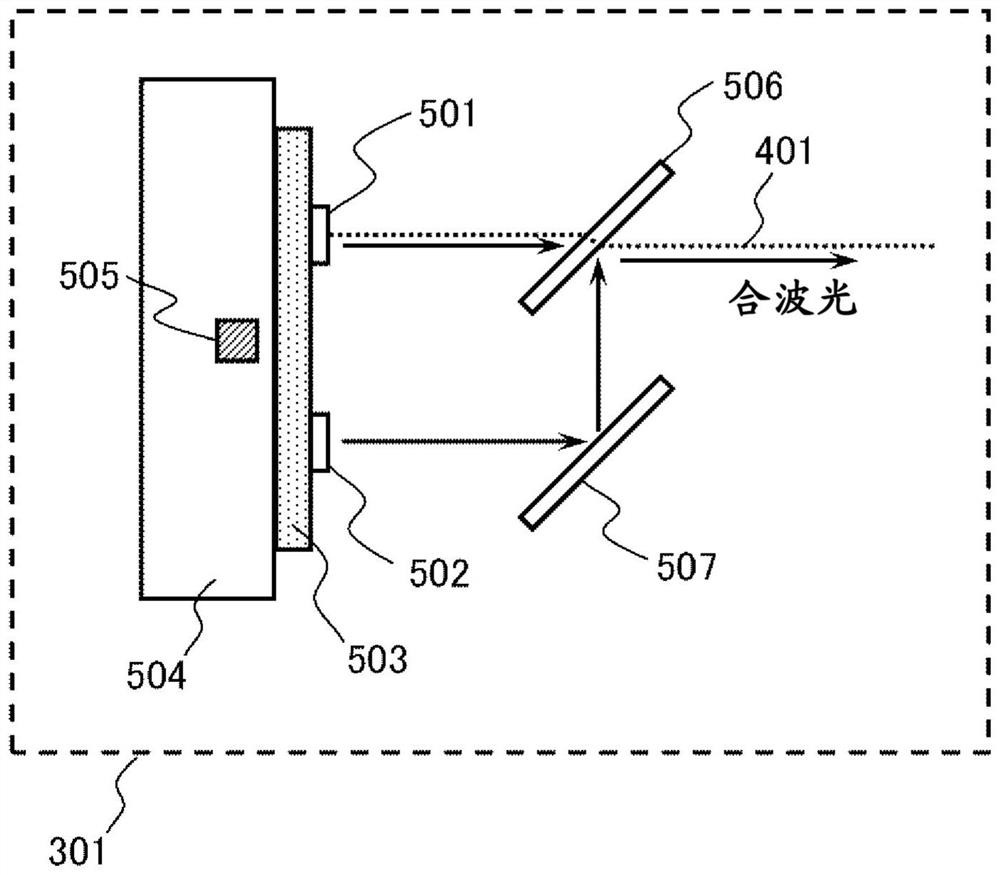

[0063] Figure 6A This is an example of the configuration of the light source unit 301 included in the automatic analyzer 10 according to Embodiment 2 of the present invention. In the second embodiment, by diffusing the emitted light of the second LED 502 , the light intensity distribution of the emitted light of the second LED 502 is made uniform on the light receiving surface of the light receiver of the spectroscope 302 . The other structures are the same as those of the first embodiment.

[0064] When the effective light-emitting area of the LED light source is 1.0 mm square, it is necessary to design only the optical axis of the first LED 501 to coincide with the optical axis 401 incident on the beam splitter 302 in order to obtain a light quantity capable of quantitative analysis with high accuracy. However, in this case, it is difficult to make the outgoing optical axis of the second LED 502 coincide with the optical axis 401 entering the beam splitter 302 . In this...

Embodiment approach 3

[0080] In order to stably obtain the analytical performance of the absorption analysis of the automatic analyzer 10, it is preferable that the light quantity of the light source unit 301 is always constant. As means for keeping the amount of light constant, temperature control of the LED mounting board 503 and drive current control of the LEDs can be used. Therefore, in Embodiment 3 of the present invention, a control procedure for stabilizing the light quantity of the automatic analyzer 10 will be described. The configuration of the automatic analyzer 10 is the same as that of the first to second embodiments.

[0081] For example, as an LED that generates ultraviolet light with a wavelength of 340 nm or less, AlGaN crystal, which is a compound semiconductor, is used. In the case of using AlGaN crystal as the light-emitting layer, the luminous efficiency of the ultraviolet LED is a fraction to one tenth lower than that of the InGaN crystal used in the light-emitting layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com