Method for calculating breakage rate of core fuel element coated particles of pebble-bed high-temperature gas cooled reactor

A high-temperature gas-cooled reactor and fuel element technology, applied in the field of reactor engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be further described below with reference to specific embodiments and accompanying drawings.

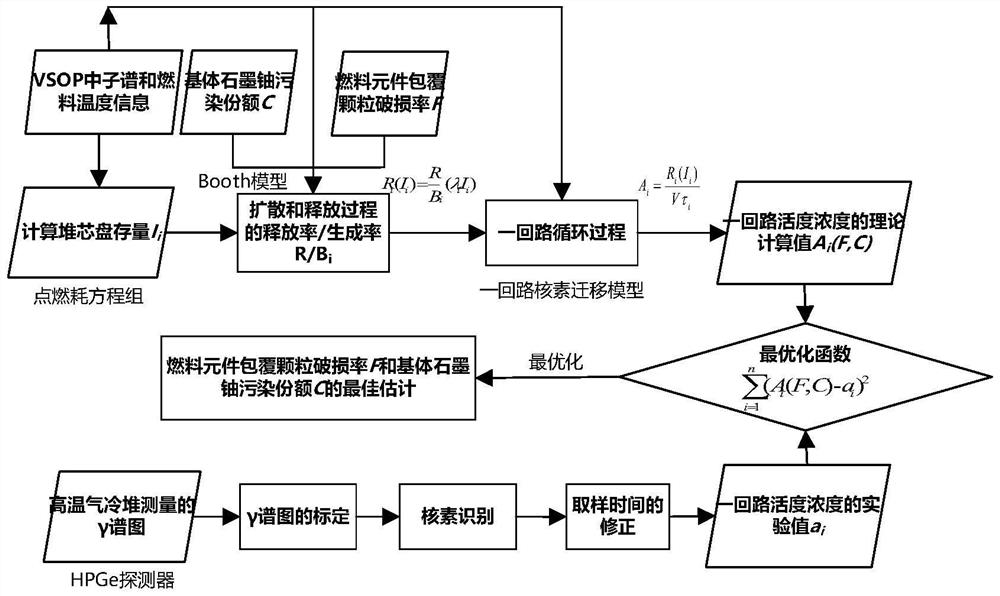

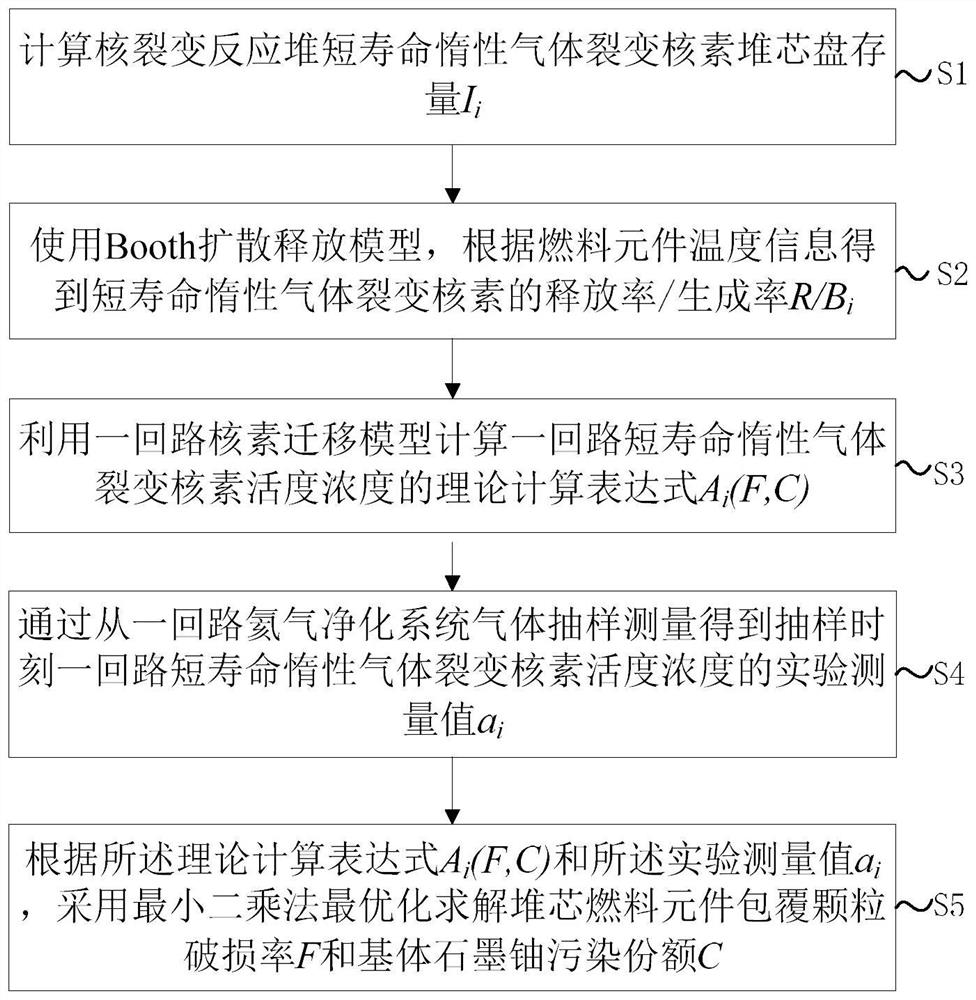

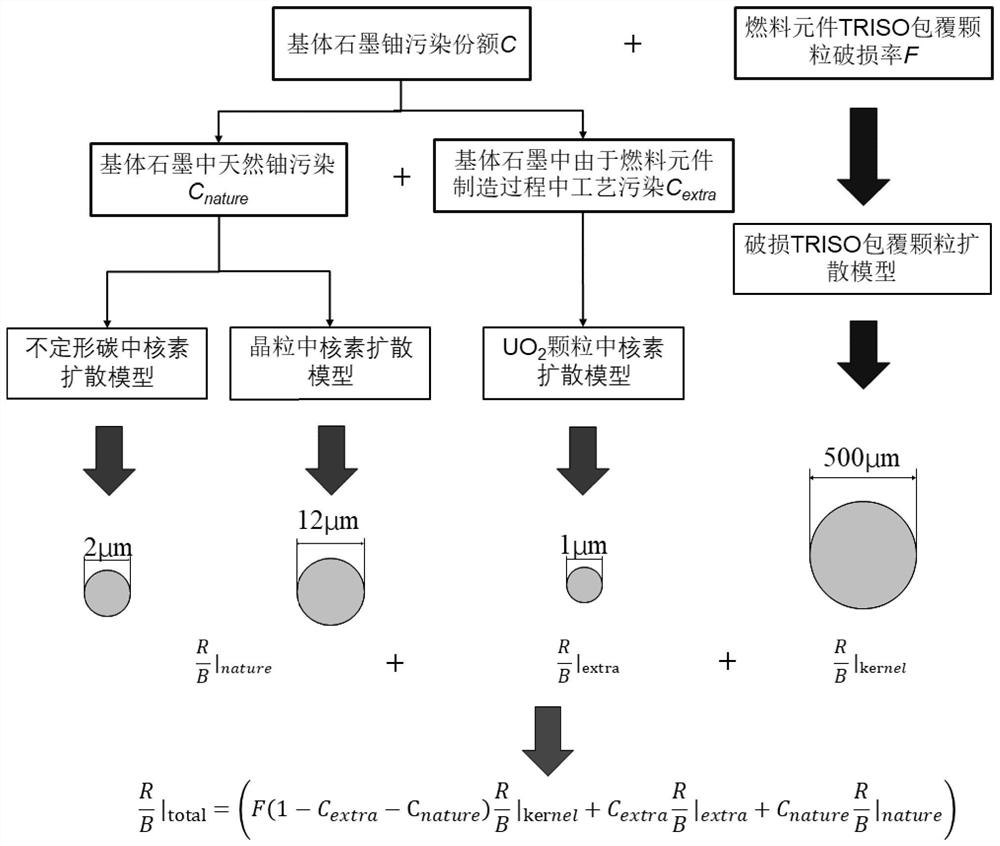

[0105] The present invention provides a method for calculating the damage rate of cladding particles of a pebble bed type high temperature gas-cooled reactor core fuel element, the general idea of which is as follows: figure 1 As shown, the performance and state of the core fuel elements are monitored by the activity concentration of the primary inert gas, which is divided into two parts: theoretical calculation and experimental measurement. Activity concentration A of short-lived noble gas fission nuclides calculated by theory i (F, C) and the actual measured primary short-lived noble gas fission nuclide activity concentration a i The least square method is used to optimize the core fuel element coating particle damage rate F and the matrix graphite-uranium pollution share C.

[0106] Theoretical calculation idea: First, use the IPRFGN simplifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com