Automatic sand discharging inspection device and method for sand supply tank of high-pressure water jet cleaning equipment

A high-pressure water jet, automatic inspection technology, used in abrasive feeding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in ensuring accuracy and real-time performance, and huge manual inspection workload, reducing labor costs. Detect the strength and ensure the effect of surface cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

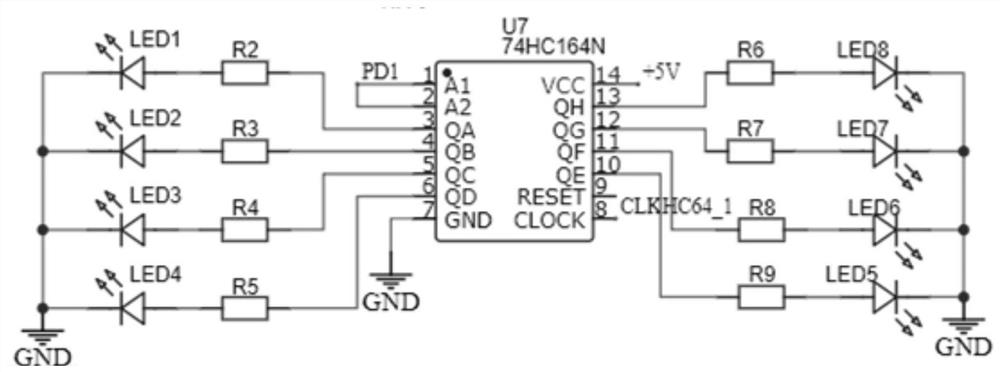

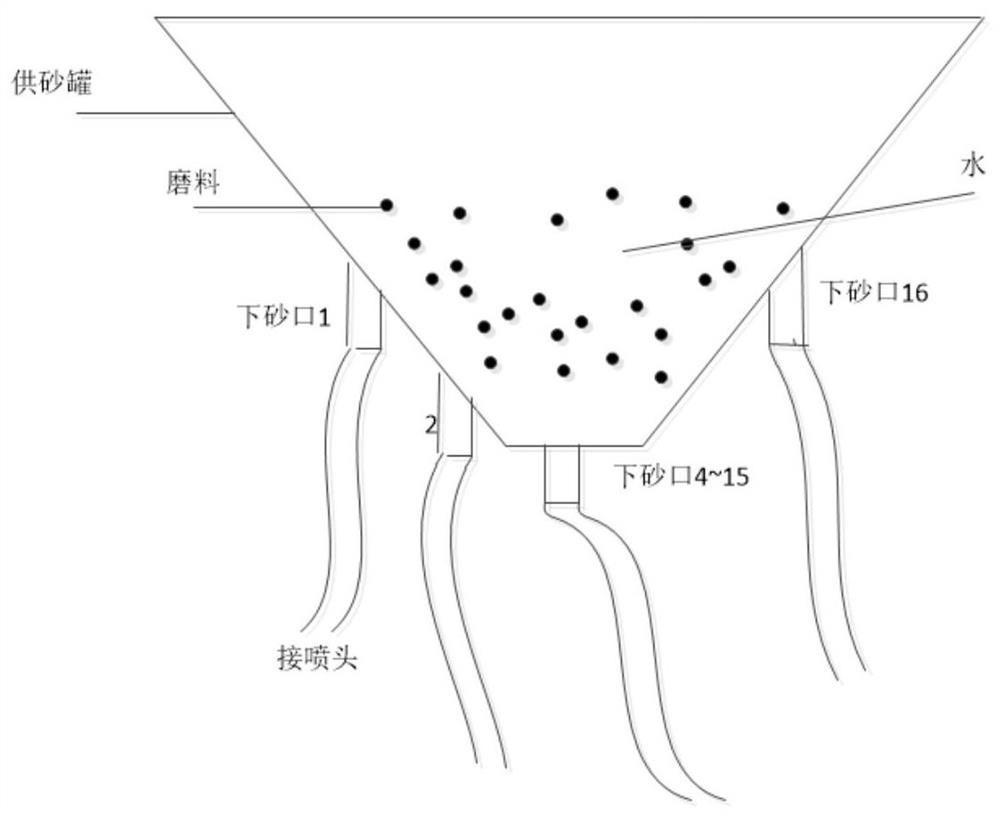

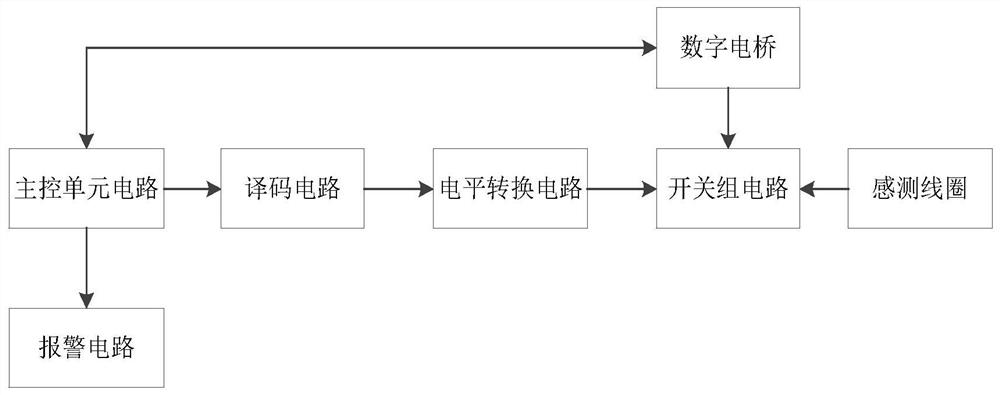

[0040] see figure 2 , the high-pressure water jet cleaning equipment of the present invention automatically inspects the sand in the sand supply tank, including: a plurality of sensors, a measuring bridge (LCR) and an inspection device, wherein the plurality of sensors are correspondingly arranged in each of the sand supply tanks. At the sand outlet; the measuring bridge is used to communicate with the corresponding sensor according to the gating control of the inspection device to obtain the instantaneous inductance value of the corresponding sensor; the inspection device is used to control the automatic cycle of the measuring bridge to measure the gating in turn and obtain the instantaneous inductance value of the corresponding sensor; compare the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com