A guardrail welding device for painting boat production

A welding device and guardrail technology, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of position deviation and poor welding effect, and achieve the advantages of convenient welding work, good support and limit function, and high adjustment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

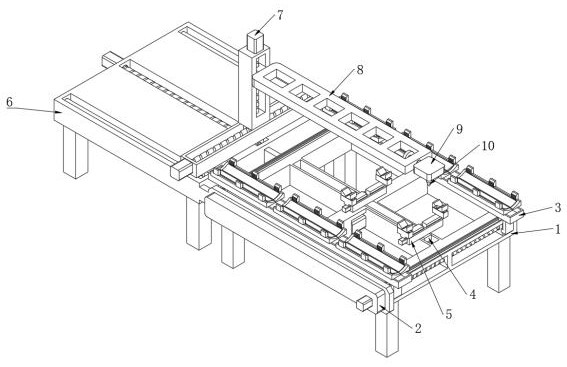

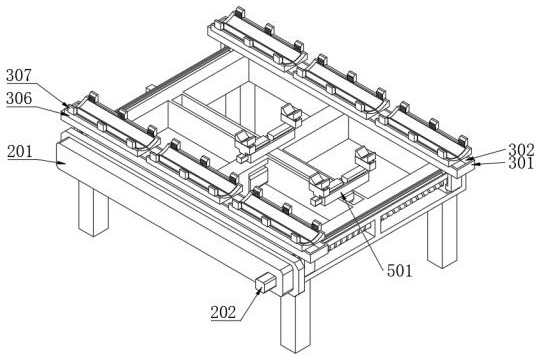

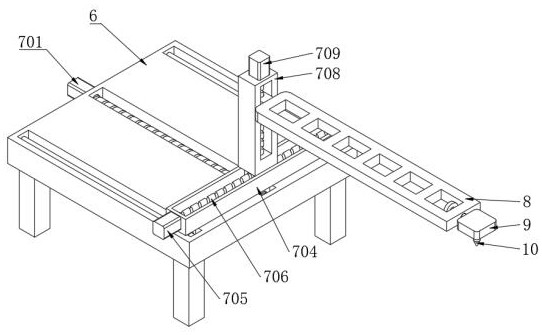

[0038] like Figure 1-13 As shown, a protective fence welding device for boat production includes a workbench 1, a first workpiece support mechanism 3 is movably installed on both sides of the upper surface of the workbench 1, and a first adjustment mechanism 2 is installed on one side surface of the workbench 1. , the middle of the upper surface of the workbench 1 is provided with a second adjustment mechanism 4, the upper surface of the workbench 1 is movably installed with a second workpiece support mechanism 5, and one end of the workbench 1 is fixedly installed with a mounting frame 6. The upper end is provided with a control mechanism 7, the upper end of the control mechanism 7 is movably mounted with a support frame 8, the other end of the support frame 8 is rotatably provided with a mounting block 9, and the bottom of the mounting block 9 is mounted with a welding torch 10.

[0039] In this embodiment, the first adjustment mechanism 2 includes an installation box 201, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com