Remote monitoring system for diesel generating set

A technology of diesel generator set and remote monitoring system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

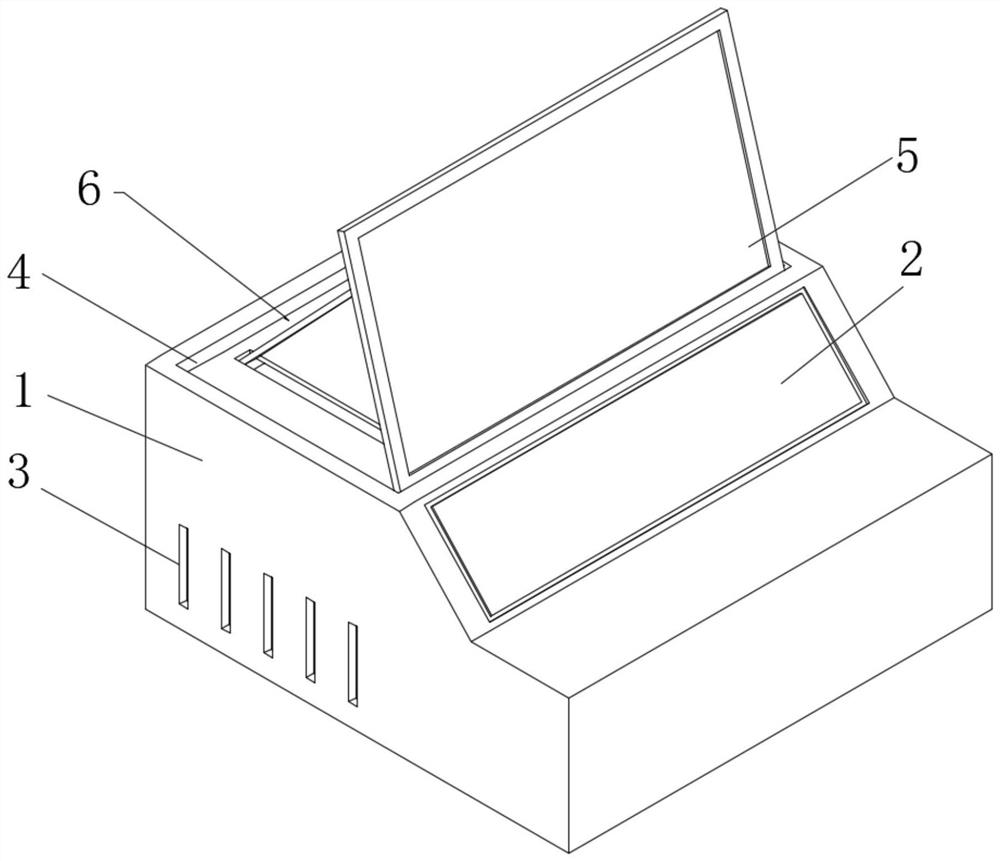

[0034] refer to Figure 1-5 , the embodiment of the present application discloses a remote monitoring system for diesel generator sets, including a main body 1, a control module 2 is arranged on the front of the main body 1, a number of sets of cooling grooves 3 are opened on the two inner side walls of the main body 1 near the bottom, and the upper end of the main body 1 is provided with storage Slot 4, a display module 5 is arranged near one side between the inner side walls of the storage slot 4, and an adjustment mechanism 6 is arranged between the inner bottom end of the storage slot 4 and the display module 5;

[0035] It also includes acquisition sensors, anomaly detection modules, surveillance cameras, cloud servers and data centers. The output ends of the acquisition sensors and surveillance cameras are all electrically connected to the input ends of the anomaly detection module, and the output ends of the data center are respectively connected to the cloud server and ...

Embodiment 2

[0049] refer to Figure 1-4 , the embodiment of the present application discloses a remote monitoring system for diesel generator sets, including a main body 1, a control module 2 is arranged on the front of the main body 1, a number of sets of cooling grooves 3 are opened on the two inner side walls of the main body 1 near the bottom, and the upper end of the main body 1 is provided with storage In the slot 4 , a display module 5 is arranged near one side between the inner side walls of the storage slot 4 , and an adjustment mechanism 6 is arranged between the bottom end of the storage slot 4 and the display module 5 .

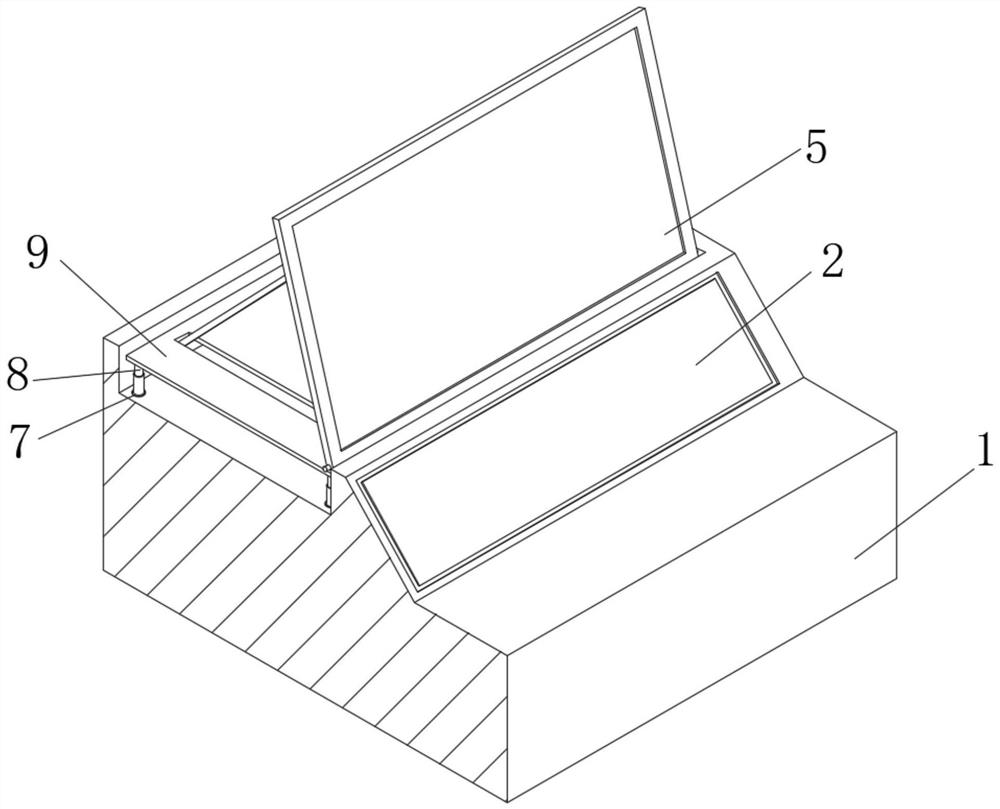

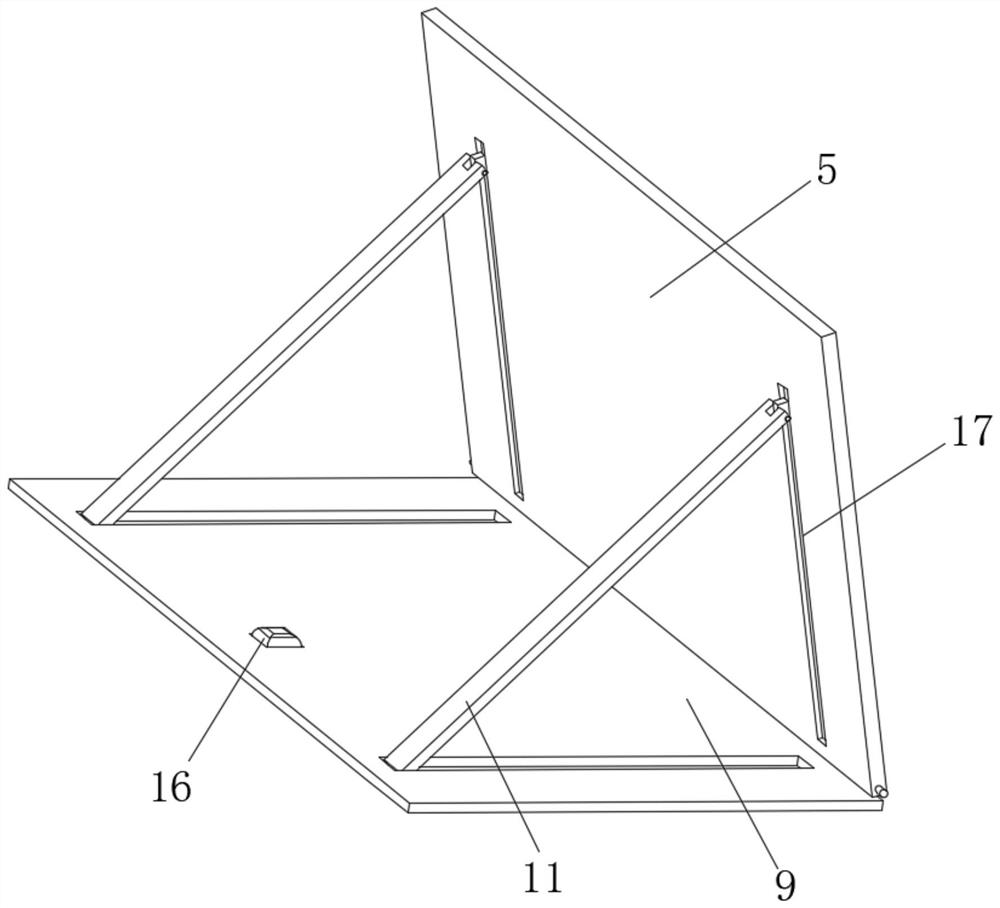

[0050] refer to Figure 2-4 , the adjustment mechanism 6 includes a lifting plate 9, the inner bottom end of the storage slot 4 is provided with a groove 7 near the corners, the groove 7 is provided with an electric telescopic rod 8, and the top of the electric telescopic rod 8 and the bottom end of the lifting plate 9 are close to the edge The angular posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com