LLC high-frequency transformer and assembling method

A high-frequency transformer and assembly method technology, applied in the field of transformers, can solve the problems of low work efficiency, low winding efficiency, large air gap, etc., and achieve the effect of improving winding and installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

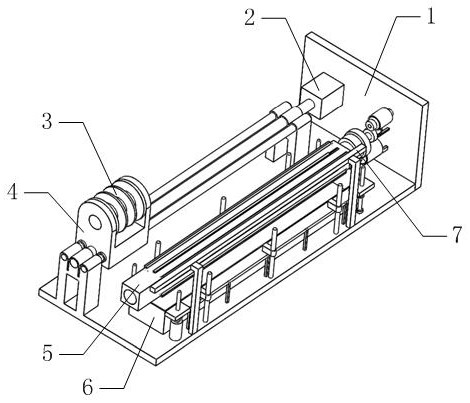

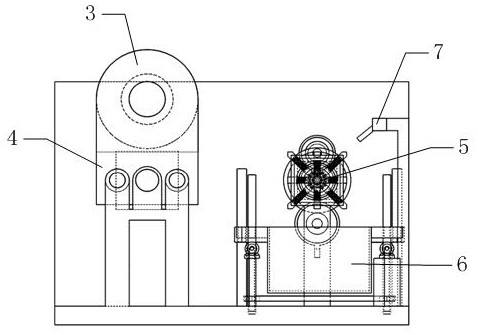

[0105] Embodiments: When using the transformer of the present invention, before assembling the transformer, coils need to be wound first.

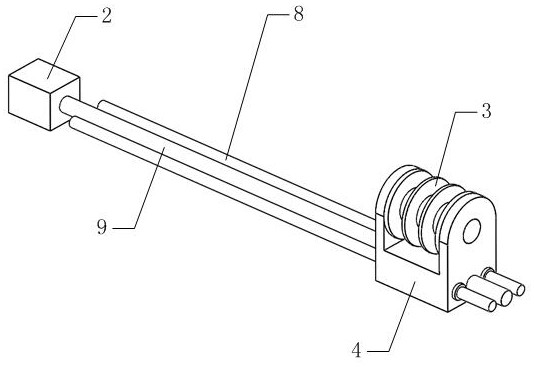

[0106] The specific winding method is as follows: the first motor 2 and the third motor 21 are controlled to work, the third motor 21 will drive the mounting shell 19 to rotate, and the mounting shell 19 will rotate to drive the mounting inner shell 20, the first support slide 16 and the second support slide 17 spins. The first motor 2 works to drive the first threaded rod 9 to rotate, and the first threaded rod 9 drives the mounting slider 4 to slide under the action of the thread, and the sliding of the mounting slider 4 drives the winding wheel 3 to slide. While sliding along the two first guide sliding bars 8 , the winding wheel 3 is pulled and rotated by the rotating winding roller 5 through the wire resistance, and the wire resistance on the winding roller 5 is wound on the winding roller 5 . By controlling the first motor 2, the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com