High-temperature and high-pressure vertical pipeline pump

A vertical pipeline, high temperature and high pressure technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems of cavitation, short service life of bearings, high temperature of bearing box oil chamber, etc., to prevent bearing temperature The effect of raising and lowering the load and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

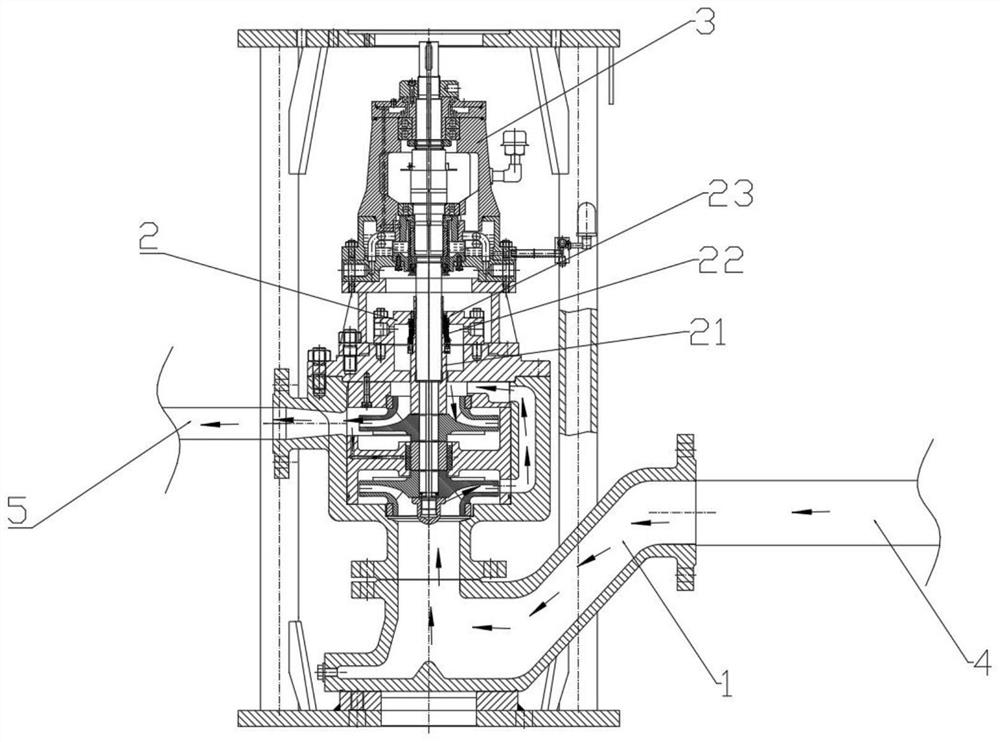

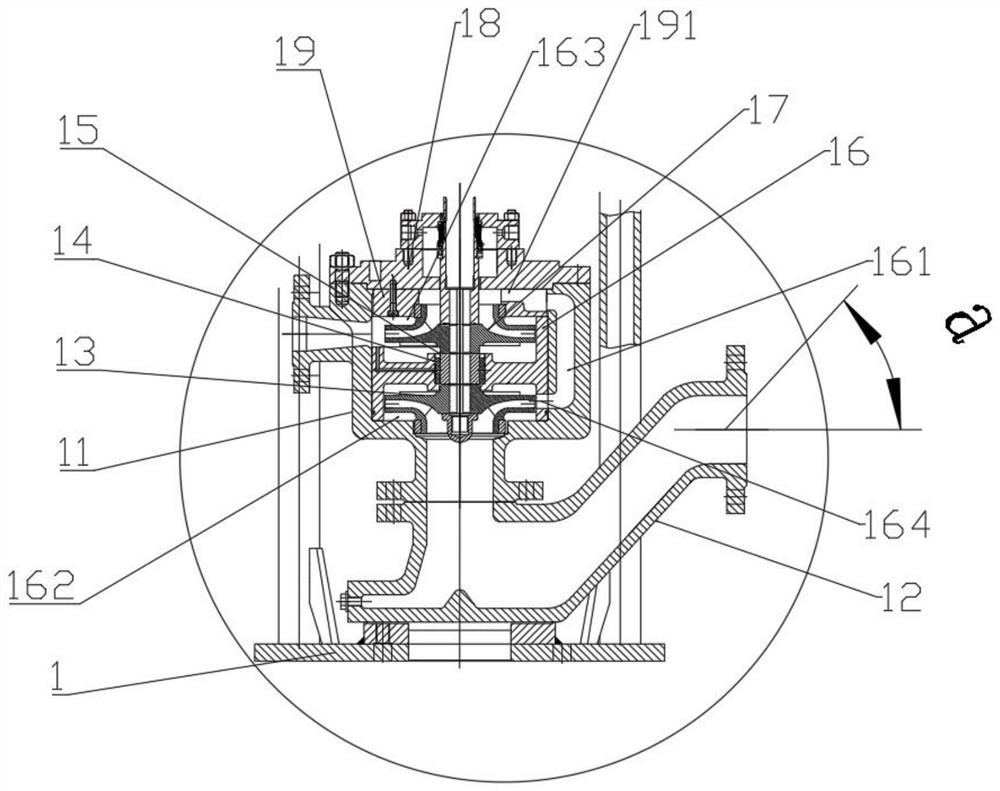

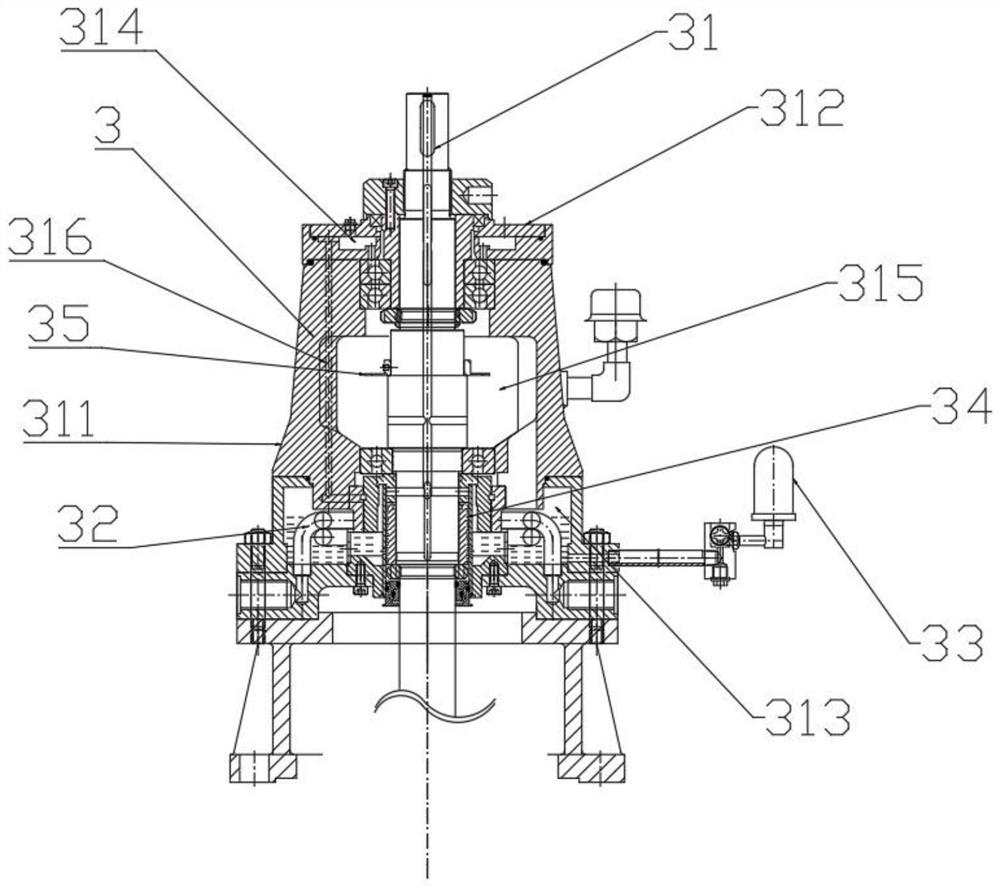

[0030] see Figure 1-Figure 4 , a high temperature and high pressure vertical pipeline pump, including a flow unit 1, a sealing unit 2 and a rotating shaft unit 3, the flow unit 1 is connected to the input pipe 4 and the output pipe 5, and provides the power for the flow of the medium in the pipeline, The sealing unit 2 is arranged between the overcurrent unit 1 and the rotating shaft unit 3, connects the overcurrent unit 1 and the rotating shaft unit 3 and isolates the overcurrent unit 1 and the rotating shaft unit 3, and the rotating shaft unit 3 includes The pump shaft 31 passes through the sealing unit 2 and is connected to the centrifugal impeller arranged in the flow unit 1, and the other end extends out of the rotating shaft unit 3 and is connected to the driving device. The driving device drives the centrifugal impeller through the pump shaft 31. The impeller rotates to pressurize the flow of the medium through the in-line pump.

[0031] see figure 2 , the overflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com